Biocatalysis has emerged as a pivotal technology within the pharmaceutical industry and is revolutionising the research, development and manufacturing of small- and large-molecule APIs/HPAPIs.

During the past two decades, the uptake and incorporation of biocatalysis in the pharmaceutical sector has seen tremendous growth, broader implementation and more sophisticated application.

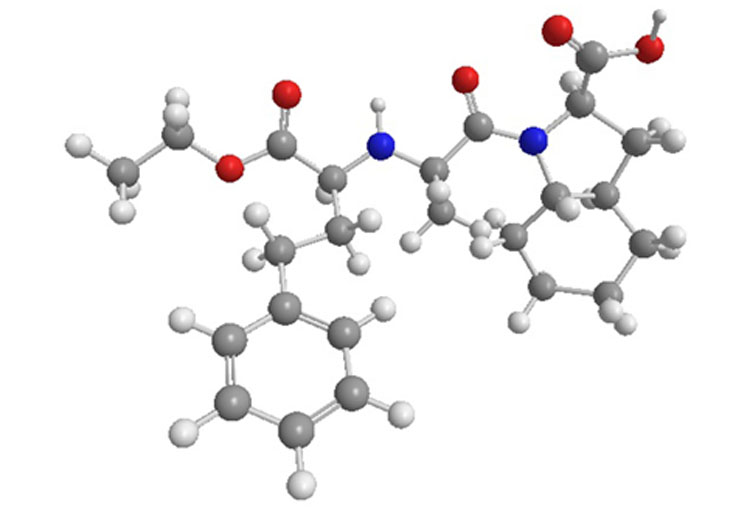

Enzymatic catalysis has several major benefits as an enabling active pharmaceutical ingredient (API) synthetic technology, including the ability to mediate chemical transformations with exquisite chemo-, regio- and enantioselectivity.

Thanks to recent advances in biotechnology, protein engineering and the 2018 Nobel Prize in Chemistry — awarded to Gregory Winter, George Smith and Frances Arnold for the concept of direct enzymatic evolution — the synthetic enzymatic toolbox has expanded significantly in the pharmaceutical research and development (R&D) industry.

This capability is paramount in terms of augmenting the application of wild-type enzymes to unconventional substrates while bolstering their efficacy and resilience against the stringent process parameters necessary to render syntheses both commercially and ecologically viable.

The sustainable ethos underpinning biocatalysis aligns seamlessly with the burgeoning impetus towards embracing green chemistry principles.

These initiatives seek to mitigate environmental impact, both in terms of raw material utilisation and waste management, while also enhancing the safety profile of reactions — particularly at industrial scale.

Biocatalytic reactions inherently address these challenges by predominantly operating in aqueous solvents under mild temperature and pressure conditions.

However, for biocatalysis to truly embody its mantle as a sustainable technology, there is a pressing need to uphold process intensification metrics that mirror those of conventional synthetic organic chemistry.

Maximising the utilisation efficiency of biocatalysts with large substrate-to-enzyme ratios and minimising process mass intensity (PMI) are pivotal steps towards ensuring that biocatalytic reactions epitomise environmentally benign processes.

Biocatalysis in pharmaceutical R&D: benefits and challenges

From lead optimisation to large-scale manufacturing, biocatalysis has broad application throughout the drug development pipeline.

In the early stages of drug discovery, enzymes facilitate the rapid generation of diverse compound libraries, thereby accelerating the identification of promising preclinical drug candidates.

Subsequently, biocatalytic processes are integrated into synthetic routes for lead optimisation, enabling the efficient synthesis of analogues with improved pharmacological properties for structure-activity relationship (SAR) studies.

In process development and manufacturing, biocatalysis offers significant advantages in terms of efficiency, sustainability and cost-effectiveness. Enzymatic transformations allow for streamlined synthetic routes, reducing the number of steps and minimising waste generation.

Biocatalytic processes also often exhibit high yields and productivity, leading to improved process economics. Furthermore, biocatalyst production scale-up is predictable and straightforward, shortening the time-to-market of new products under development.

The traditional application of biocatalysis in late-stage development has remained a fundamental focus of this technology.

Unlike the early development phase, when project attrition rates are typically higher, late-stage development benefits from positive clinical data readouts; these help when it comes to investing in the dedicated design and development of bespoke biocatalysts to industrialise target molecule transformation.

Although early stage candidates are often associated with high failure rates in clinical development, biocatalysis also provides benefits during the discovery process by accelerating translational research from preclinical to clinical development.

In early stage chemistry, manufacturing and controls (CMC) phases, timeframes and resources are often constrained owing to the concurrent progress of multiple projects.

Therefore, for biocatalysis to make a significant impact, synthetic solutions must be swiftly scaled-up to deliver cGMP API material for early biological testing and, ultimately, for Phase I (first-in-human) studies.

This leads to reactions being enabled with “off-the-shelf” enzymes (wild type and commercially available) and processes that are fit-for-purpose to deliver cGMP material.

For selected enzyme classes, libraries of variants are commercially available for biocatalyst screening (lipases, transaminases, hydrolases, oxidoreductases, glycosyltransferases, decarboxylases, aldolases, etc.), which often display highly desirable enantiocomplementary selectivity.

However, despite intense efforts, certain types of enzymes are still not (yet) available for large-scale production — often because of poor turnover numbers and insufficient protein stability under process conditions.

This may be addressed by identifying alternative options or improved variants.

Despite its numerous benefits and extreme versatility — from laboratory scale synthesis to industrial production — the widespread adoption of biocatalysis in the pharmaceutical industry still faces challenges such as enzyme stability, substrate specificity and scalability, to name a few.

The advancements and ongoing research aimed at enzyme engineering, immobilisation and recycling, bioprocess optimisation and bioreactor design are increasingly expanding the applicability of biocatalysis in API synthesis.

In the years to come, flow chemistry will undoubtedly become the default solution in pharma R&D to overcome the well-known limitations of “classic” enzymatic catalysis.

The rise of flow biocatalysis

Continuous flow biocatalysis is the ultimate evolution of biocatalysis and has brought enzymes to a whole new dimension. The rapid and exciting progress in the field of enzyme immobilisation techniques and microreactor technology (MRT) has prompted a renaissance in the field of flow biocatalysis research.

This revival derives from the ability to combine the strengths of microreactors with biocatalysts to make enantioselective synthetic routes more industrial and ecofriendly.

Improved heat/mass transfer, faster reactions, process intensification, easier scale-up/technology transfer, R&D cost savings and expedited development-to-market timeframes are just some of the benefits of continuous bioenzymatic flow processes.

From an application perspective, flow chemistry and biocatalysis can be used to optimise process chemistry metrics (yield, chemo/regio/stereoselectivity, E-factor) and safety/environmental/quality profiles (compared with “standard” chemistry).

The asymmetric amination of ketones/aldehydes, the oxidation of amines and alcohols, the asymmetric reduction of ketones and the hydroxylation of alkanes and fatty acids are just a few examples of reactions that have recently become mature enough to be exploited for API synthesis.

However, fundamental challenges remain; the most obvious omission from the biocatalytic toolbox is a broad-spectrum way to make C–C bond forming methods more efficient.

Several research programmes are under way at Farmhispania Group (FHG). Key foci are the chemical development of a continuous and biocatalytic process to support clinical trials and the commercial launch of custom APIs/HPAPIs.

Continuous flow biocatalysis offers new ways to explore novel processes at large-scale, filling a current gap in pharma R&D between medicinal and process chemistry.

To respond to the rising number of chiral and complex APIs/HPAPIs that require ever more specialised and niche chemistry, the research in this field must become a pivot point for the sustainable development of tomorrow’s pharmaceutical industry.

At FHG, several “proof-of-scalability” trials (>100 kg) have already been done and a wide range of bioenzymatic reactions are at the “proof-of-concept” stage in our R&D labs, ready to be exploited for scale-up.

The new and ongoing investments in flow chemistry and biocatalysis are important milestone for the long-term strategy and vision of FHG to develop new R&D pipelines for our pharmaceutical customers.

New horizons for enzymes

Although the research community continues to increase the number of scientific publications and patents in this field, the scale-up and industrialisation of flow bioprocesses is still quite limited — mainly because of the lack of off-the-shelf equipment for large-scale packed-bed flow reactors (compared with coil- and plate-type reactors) and a lack of efficient enzyme immobilisation techniques.

Aiming to broaden the potential of flow biocatalysis, academia and industry are increasingly partnering to design and develop novel solid-supported enzymes that are practical and facilitate catalyst separation/recovery operations.

A rational approach to the development of new and/or improved polymers for solid-phase catalysis is an essential design factor if future biocatalysis research is to cover this technology gap.

It’s well known that some of the polymers that are currently used as support materials for solid-phase catalysis (PS, PEG, pAAM, etc.) suffer from the “swelling effect” in organic solvents, which negatively affects biocatalytic performance.

Another essential contributor to the success of flow biocatalysis in the API process chemistry space is that the pharmaceutical industry needs to invest in educational programmes to train the next generation of chemists and engineers in this vibrant new research area.