From June 10-14, 2024 Optima will be at ACHEMA in Frankfurt am Main. At the world's leading trade show for the process industry, the packaging and filling equipment provider will present its complete, integrated turnkey solutions for the pharmaceutical and biotech industries. Visitors at the booth A73 in hall 3.0 will get an exclusive look at a highly flexible MultiUse system with isolator, the sterility test isolator STISO, and the new LYO-SCALE freeze dryer for scale-up processes.

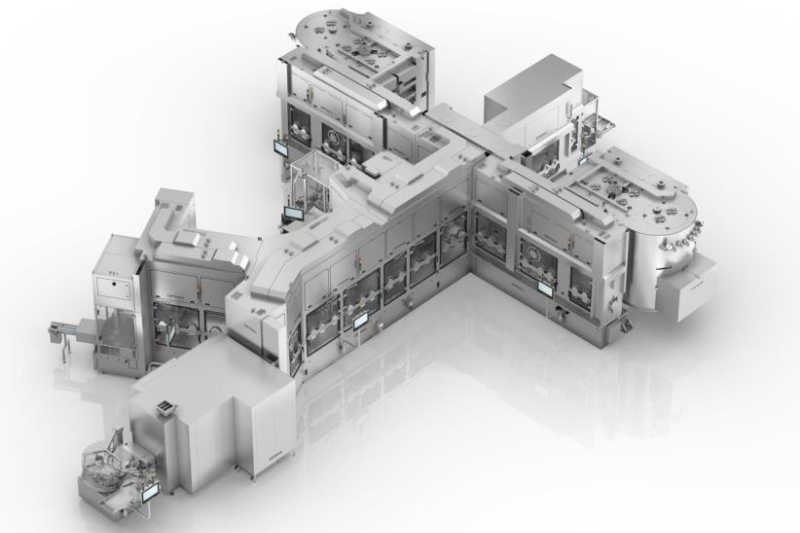

Optima has a unique position in the market as an expert in turnkey systems comprised of filling lines, isolators, and freeze dryers. Its integrated complete solutions from a single source include filling and closing of various products, as well as containment and freeze-drying systems. At ACHEMA, the technology leader from Schwäbisch Hall, Germany will be exhibiting the MultiUse filling line, the latest sterility test isolator STISO, and the new LYO-SCALE freeze dryer. Visitors will gain comprehensive insight into the three components of a turnkey system.

"With our turnkey approach for filling systems, freeze dryers, and isolators, we ensure that all components fit together seamlessly and that our customers benefit from maximum safety,” says Matthias Poslovski, Vice President Sales at Optima Pharma. "Only when every component is perfectly matched you can assure safe and smooth production.”

Live experience on the booth

Flexibility and innovation - this is Optima's MultiUse portfolio. From R&D product and process development to clinical studies and commercial production, the system portfolio covers all applications and performance ranges. The MultiUse is flexible and cost-effective and handles different types of containers including vials, syringes, and cartridges. As turnkey partner, Optima integrates all process steps, including isolator and freeze dryer, to provide a complete solution. The integrated filling solution with isolator will be demonstrated at booth A73 in hall 3.0

"Processing of highly sensitive pharmaceutical or biotech products requires maximum safety. Our holistic turnkey approach of filling machines with isolators meets the highest requirements," explains Matthias Aster, Director Sales at Optima Pharma.

Isolators are used in a wide variety of applications, with one thing in common: Providing maximum safety and protection. Optima's sterility test isolator STISO ensures batch sterility through stable testing and fast, reproducible decontamination. Modularly adapted to production, it accelerates processes and the path to batch release. The latest version of the STISO will be on display at Achema.

Visitors will also be able to experience Optima’s new freeze-drying solution. With the OPTIMA LYO-SCALE, recipe parameters for lyophilisation processes can be developed on a small scale and precisely scaled-up for larger systems. Optima's lyophilisation solutions preserve highly sensitive pharmaceutical or biotech drugs and ensure maximum shelf life. Integrated into a filling line with isolator, they provide customers a complete turnkey system.

The Expert Zone offers more displays of isolator technology and digitalisation. Experts will be on hand to discuss turnkey solutions, bio-decontamination, glove minimisation, digitalisation, and Annex 1.

Optima's experts are already providing additional insights into the highlights of the booth at: www.optima-packaging.com/achema-en

At ACHEMA, the technology leader from Schwäbisch Hall, Germany will display its MultiUse filling line. Visitors will see an integrated filling solution with an isolator