Designed to dissolve rapidly in a glass of water, these user-friendly formulations help to overcome the unpleasant effects that many individuals experience when swallowing conventional tablets and capsules.

A recent study revealed that — depending on tablet or capsule size, shape and surface texture — almost half of us find swallowing traditional oral dosage forms difficult or uncomfortable.1 The unpleasant taste and odour that patients and consumers often experience can also be a factor that contributes to poor adherence to treatment regimens.

Effervescent tablets and instant drinks, by contrast, offer an easy and more pleasant oral experience. These dosage forms undergo effervescence upon exposure to water, allowing the active pharmaceutical ingredient (API) or nutrient to be rapidly released into a solution for the patient to drink as a beverage.

The application of taste-masking and flavouring technologies in formulation development makes it possible to design products that taste pleasant and can even be enjoyed. In addition, the fact that these formulations allow large amounts or even multiple APIs to be delivered in a single dose means effervescent tablets and instant drinks offer a very versatile approach to oral administration.

Owing to the moisture-sensitive nature of these formulations, specialist granulation expertise is required to create high-quality and stable products with a shelf-life of up to 3 years and usability in hot and humid climates (climate zones III–IV). In this article, we look at the granulation technologies that are available when developing effervescent tablet and instant drink formulations and highlight the factors that should be considered when making this choice.

The importance of granulation

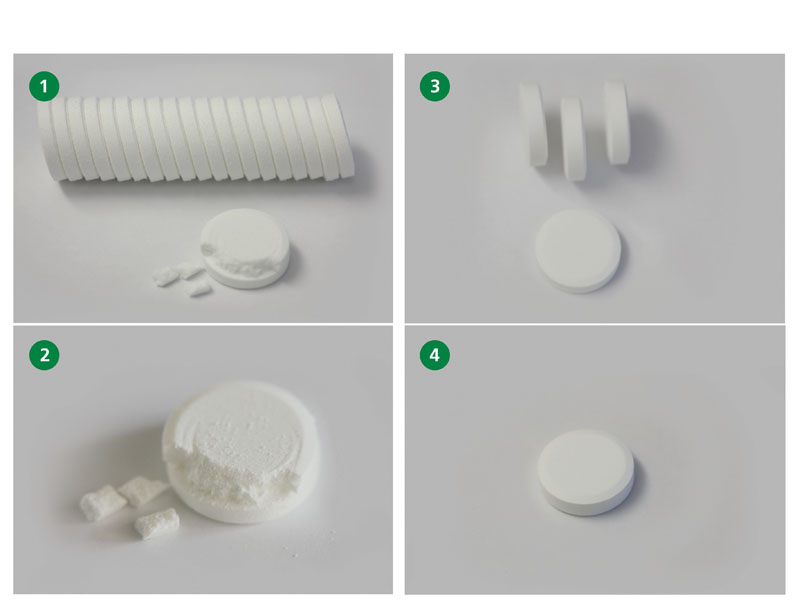

Granulation is a key step in the development and later manufacture of effervescent dosage forms (Figure 1). Pharmaceutical powders, such as active ingredients and excipients, typically contain a broad distribution of particle sizes that can make processing difficult. Granulation is used to transform these fine powders into larger granules of a consistent size, which can be more easily processed in subsequent production steps.

Figure 1: Comparison of a conventional wet granulation method (1 & 2) and TOPO granulation (3 & 4) to manufacture an effervescent painkiller

The formation of dust-free granules enhances the flowability of materials — a factor that is necessary to control API dosage and deliver a homogenous distribution of actives within products. This is important to ensure that they perform as intended when taken by patients. Granulation is also important to achieve a narrow particle size distribution, which is beneficial for reliable and cost-effective product manufacture.

Granulation breaks down awkwardly shaped needle-like particles, which would otherwise be impossible to further process. Adjusting granule morphology also affects API bioavailability, allowing the release profile of the active ingredient to be tuned according to the requirements of the finished product.

Importantly for moisture-sensitive effervescent formulations, granulation can be used to reduce the accessible surface area of the reactive components. As the stability of effervescent products is related to the contact area of the active ingredients, granulation results in the manufacture of more stable products — as the active ingredients cannot interact through surface interactions.

When it comes to the technologies that are used for granulation, two approaches are commonly adopted: dry granulation, whereby primary powder particles are bonded together by physical compaction, or wet granulation, achieved through the addition of a solvent to form larger, multiparticular granules.

Dry granulation

For many non-effervescent formulations and some less-reactive effervescents, dry granulation is an efficient manufacturing option. The most common method of dry granulation is roller compaction, whereby a powder is compacted between two counter-rotating rollers and then compressed into a ribbon.

This ribbon is further processed via milling to generate particles of the desired size. Roller compaction is a high-throughput method that can be operated continuously with minimal supervision.

As no liquids are used, the method does not involve costly and time-consuming drying steps. Furthermore, any material that does not meet the required particle size can be recycled back in the process, minimising waste. As a result, this approach to granulation can be very cost-effective in cases when processability and the morphology of particles need to be improved.

However, when it comes to the manufacture of more reactive effervescent products, dry granulation is often not suitable as the effervescent components are compacted without passivation. This passivation step is important to stabilise the reactive ingredients and maintain product quality during manufacture, shipping and storage. As a result, more advanced technologies are required.

Granulation is a key step in the development and later manufacture of effervescent dosage forms

TOPO granulation

TOPO vacuum granulation is a patented wet granulation technology designed to stabilise the moisture-sensitive components of effervescent dosage forms in air, whilst ensuring they react rapidly and completely in water.

TOPO granulation modifies the surface of the reactive acidic components within effervescent mixtures (most commonly citric acid) causing a layer of less reactive citrate to form on the surface of the acid particles, passivating them.

The vacuum allows manufacturers to achieve lower drying temperatures and shorter drying times, decreasing the likelihood of any thermal degradation occurring to the effervescent components or the APIs and resulting in a more cost-effective production process. It also prevents uncontrolled effervescent chain reactions from occurring — a factor that is important for the creation of consistent, high-quality products.

The use of TOPO granulation offers a very effective means of producing effervescent tablets that remain stable even when packaged in tubes that are repeatedly opened and exposed to air and humidity, such as in bathrooms.

As a result, the technology is ideal for the production of medicinal products and food/dietary supplements designed for tropical and high-humidity regions. Moreover, because TOPO allows the manufacture of effervescents under conditions of up to 30% humidity, the technology can help to minimise the costs associated with air conditioning in manufacturing plants.

TOPO granulates also have excellent compressibility characteristics, leading to effervescent tablets with high physical stability. This avoids the tablets breaking during transport or when a tablet is removed from the tube, while maintaining their rapid dissolvability. Furthermore, the particle size distribution of granules can be modified so that they can be easily blended with other excipients.

Unlike other methods, the pure water used in TOPO granulation ensures that there are no solvent residues left in the finished product. TOPO granulation also minimises or avoids the need for insoluble excipients, which can lead to unattractive foams or films when the tablet is dissolved in water.

In addition, as TOPO technology requires only a small amount of water and no organic solvents, it is a more environmentally friendly, sustainable and cost-efficient method of manufacturing effervescent products.

Continuous flow

Continuous flow (CF) technology is a further development of TOPO granulation that’s specifically designed for the high-throughput manufacturing of effervescent products. The process is performed within an inclined drum, with the primary particle powder being fed in at one end and the granules collected from the other.

CF allows the manufacture of up to 10 tons of granules every day and is a very economical approach for the production of highly stable effervescent tablets and granules. As such, CF is often the most appropriate solution when large volumes of product are required, especially when they contain sensitive APIs, such as calcium and vitamin D3.

Conclusion

Effervescent tablets and instant drinks are user-friendly alternatives to traditional oral dosage forms and help to overcome the unpleasant effects that many patients and consumers experience when swallowing conventional tablets and capsules.

Granulation plays an important role in the development and manufacture of these products, helping to turn fine powders into free-flowing, dust-free granules, which can be processed more easily.

Although traditional dry granulation strategies can be used for the production of some effervescent products, when more sensitive active ingredients are involved, these approaches perform less effectively. Advanced technologies, such as TOPO and CF granulation, enable effective passivation of the reactive effervescent components, ensuring optimal stability, usability and overall quality of the final product.

Reference

1. www.swallowingtablets.com