A stronger focus during the clinical stages of development on longer-term commercial packaging considerations may lead to both cost and time efficiencies in terms of commercialisation, reports Gary Butler, Vice President and General Manager, Commercial Operations Europe, PCI Pharma Services.

Partnering with a single vendor that has experience across the entire clinical-to-commercial spectrum may offer far more value and speed to market than working with different vendors throughout the cycle.

The ongoing global pandemic has taught us that expert packaging partners have been able to help pharmaceutical companies to deliver time-critical supplies from early clinical phases to commercial launch, often with specialist cold-chain and ultra-cold chain requirements.

The industry has seen expert partners working with their clients to launch vaccines in less than 12 months from development inception.

There are some important underlying principles within this process that may reduce both potential risks and associated costs. These include planning for commercial launch early in the development cycle and working with a partner with specialist packaging design capabilities, expertise and experience across the development-to-commercial launch cycle.

Is there an opportunity to expedite launch whilst reducing costs and risk?

Historically, teams within companies have tended to focus only on the current development phase of a given product. Internal departmental structures and budget flows may have been the driving force behind this approach, with early stage R&D teams operating relatively separately to their later stage commercial launch counterparts.

Gary Butler

However, it is becoming increasingly clear that taking a more holistic approach, breaking the silos and managing the cycle as one seamless process from development to launch may offer many benefits.

For example, planning for your commercial launch requirements earlier within the clinical development cycle may reduce risk-to-launch timelines and therefore avoid unnecessary delays. Early consideration of commercial launch dates may also offer the opportunity to expedite the process, reduce costs and improve the patient experience compared with a more traditional model.

Complexity is increasing: what does that mean?

A number of factors are driving increased complexity. The growth in biologics and immunology drugs is associated with more complex product delivery. This in turn has regulatory implications, which can be better managed by working with partners with experience of clinical through to commercial packaging regulatory needs.

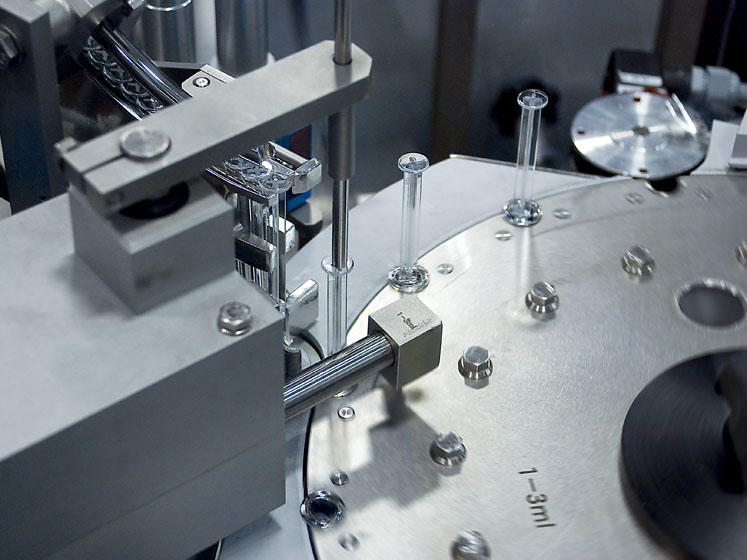

The increasing requirement of cold-chain and ultra-cold chain transportation adds further complexity, as does the constantly evolving area of actual drug delivery systems. The increased use of patient self-administration with autoinjectors and prefilled syringes creates a need for more sophisticated packaging requirements.

All such variables lead to an ever-evolving level of sophistication in packaging requirements and, in some instances, a need for bespoke packaging solutions to accommodate additional devices within one patient kit. As such, the extent of commercial packaging considerations for new innovative drugs has increased.

Broadly speaking, when dealing with non-oral combination products, there is an exponential increase in complexity, with companies having to evaluate how sterilisation procedures work with the packaging of products given via an injection or implant delivery form.

The team may have been successful when optimising the sterilisation method for the drug product; yet, they may not have considered the impact of the packaging and the packaging process … and therefore the packaging design requirements.

There is also the added complication of human factors and an increased focus on patient adherence. Historically, delivery forms such as inhalers were subject to testing with regard to human factors in terms of how the patient administers the product; however, such requirements are now starting to creep into injectables — with the US FDA expecting companies to demonstrate clear thinking with regards to human factors. This has led to a stepwise change in terms of packaging development and design needs.

It is also worth noting that for those products that are on a fast track process or designated as a breakthrough therapy, the clinical development process is hugely accelerated — meaning that CMC development may become a rate-limiting factor in terms of submission. In such instances, early decision making related to CMC is critical in terms of delivering the fastest possible launch timelines.

What are the benefits of working with a specialist and experienced partner?

There are many reasons why a company will choose to work with an external vendor. Irrespective of company size, the reasons are usually similar (with size perhaps just affecting the scale).

It may be because of internal capacity constraints or capabilities, particularly when entering new markets in which, perhaps, the specialist capabilities needed simply do not exist. Smaller companies may have a total reliance on external vendors, whereas larger ones may have a specific challenge that requires a partner.

Irrespective of the reason, there is one overarching requirement that is of critical importance: any packaging partner must be familiar with the actual manufacturing and packaging technologies because of the impact these may have on the packaging process itself.

Therefore, utilising a standalone packaging design partner that’s not intimately involved with the manufacturing or packaging process may ultimately lead to oversights, increased costs and prolonged timelines.

Is partnering with one vendor from development to launch a good idea?

If a packaging vendor has the capabilities throughout the development-to-launch cycle, it can be far simpler and beneficial compared with using one partner for the clinical phases and then changing to another for the commercial launch.

This is because a vendor with experience in all aspects of the cycle may offer a more seamless transition between the stages, using knowledge gained at each stage to inform the next, as well as ensuring a focus on the commercial launch early in the development process.

This may be especially beneficial when a global partner with an international presence is well versed in the technical and regulatory requirements of a global, multi-SKU launch programme.

There may be a need to focus on a multiregional strategy for packaging, allowing for the unique requirements of individual markets. This is especially true in the EU where there are differing mandates relating to serialisation, Braille and child-resistant packaging, to name but a few.

In the US, there are also differing needs between states with regard to the use of tamper-evident seals; therefore, engaging with a vendor who both understands regional differences and is able to navigate the associated packaging requirements would offer a clear advantage.

Put simply, working with a specialist partner that’s able to demonstrate a synergistic relationship between the clinical and commercial divisions, and operates from a central set of design standards, may drive efficiencies, result in innovation, minimise risk and deliver time and cost efficiencies.