Sticking is one of the most common issues for tablet manufacturers. It occurs when particles from the formulation adhere to the punch cup, resulting in defective tablets.

Picking is a specific type of sticking that refers to particles getting stuck in or around the logo/characters embossed on the punch face.

Sticking and picking issues are often not detected until transferring the product from development to production. When a sticking defect is noticed on a tablet, one must first identify where the sticking is occurring (upper punch, lower punch or both). The location of the sticking/picking will help in identifying the root cause.

There are as many causes of sticking and picking as there are formulations. A few of the most common are discussed below.

Tablet Design

When a tablet drawing is submitted for approval, many of those involved with the review and approval process are not familiar with the intricacies of tablet design or are not well versed in mechanical drawing.

Typically, a pharmaceutical company’s marketing department requests certain tablet shapes and logos in order to promote brand recognition and tablet identification. However, some designs may not be optimal for manufacturing requirements and demands. Experienced tablet design experts can identify potential sticking and picking issues before tablet designs are finalised, ensuring a trouble-free operation. Utilise the experience of the tool vendor during the tablet design process.

Tablet Design Solutions

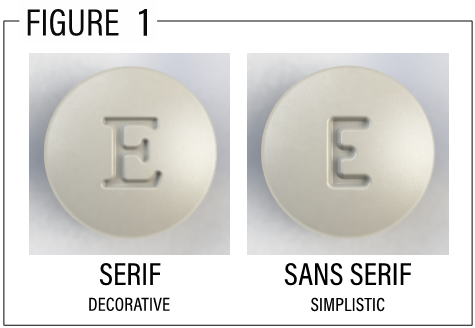

Marginal formulations that are prone to sticking require a closer look at font and logo design. For example, an ornate, decorative Serif font is more prone to picking problems while a more simplistic Sans Serif font is less likely to have issues.

Serif font has a more ornate, decorative design, but increases the risk of picking especially with marginal formulations.

Pre-Picking & Tapered Engraving Cuts

Pre-picking letter or numeral islands as well as tapering the peninsulas for some letters or numerals will often alleviate picking issues.

Picking is a term used for material that sticks to the enclosed areas (islands) and inside corners of logos, numerals, and characters. For example, picking can occur in many different numerals, such as 4, 6, 8, 9, and 0.

Pre-picking is a special engraving feature used in order to minimise or eliminate picking. A pre-picked engraving cut can be engineered to be 100% (which removes the island entirely) or, more typically, by a percentage of the engraving depth.

To reduce or eliminate problems with material picking in the enclosed islands of numerals and characters, pre-picking should be incorporated in the design. Pre-picking decreases the height of the resulting island or pad by intentionally adjusting the depth of the engraving cut.

Consideration must be given to tablets that will be coated post-compression. Therefore, it’s recommended to not exceed more than 30% pre-pick on coated tablets.

The partial pre-pick concept is applicable to any letter or numeral with fully enclosed areas (i.e., islands or pads).

Figure 1.

Tapering

Characters that do not have fully enclosed areas are also prone to picking. Letters like E, S, K, and M and numerals such as 2, 3, and 5 all contain these peninsulas.

For corners (partially enclosed areas), a feature called “tapering” is employed to reduce the likelihood of picking in these areas. Taper starts at the internal corner and ramps up to the tablet surface.

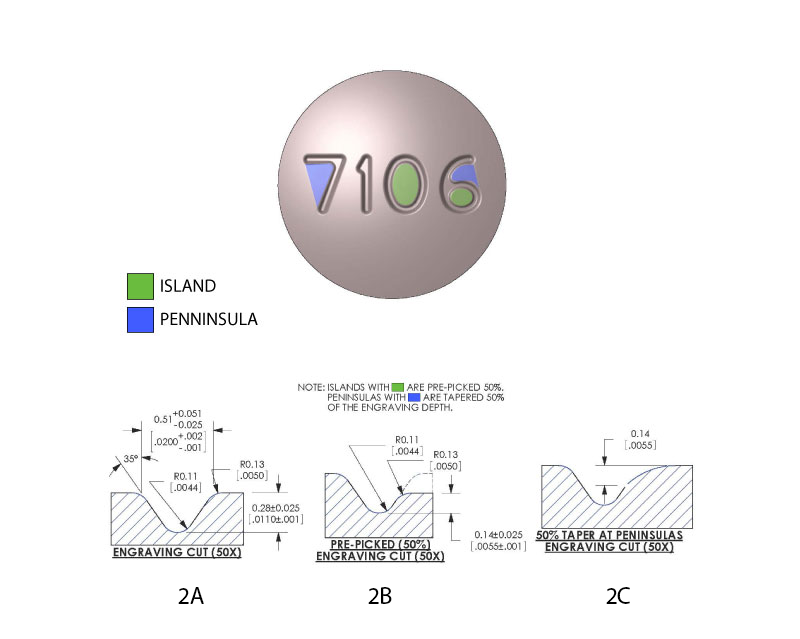

Figure 2. The risk of picking in an island or peninsula in a typical engraving cut (shown in 2A) can be reduced by decreasing the depth applying pre-pick (2B) or tapering (2C)

In figure 2, you’ll see that the peninsula (partially enclosed area of the 7 and 6), and the island (the fully enclosed area of the 0 and 6), are formed within a typeface on this typical round tablet.

The engraving of the “7106” cut into the tablet is shown in Figure 2A with typical engraving width, depth, and an angle of 35 degrees. Most product formulations can readily be compressed into tablets using tools with this style of engraving design. However, many formulations are not typical, and picking problems can still occur.

Logo/Identifier Placement

Although font selection and design of the engraving cut are two crucial aspects of tablet design, attention should also be paid to the placement of the identifier. The size and spacing of the characters can be modified to reduce the occurrence of picking. Moving the placement of the characters off center on a curved face tablet can also be an effective option, as illustrated in Figure 3.

Exploring Tooling Material

Figure 3.

If sticking has been observed, specialty grade steel types or coatings should be considered to help eliminate these issues.

It is widely accepted that high chromium punch steel, such as M340, 440C and K340, are beneficial for sticky products because the high chrome content yields improved product-release characteristics. However, steels with higher levels of carbon (D2, DC53) and vanadium (PM-3V, 9V, 10V) provide better wear resistance for abrasive formulations common in nutraceuticals, as sticking can occasionally be caused by a degradation in cup surface finish. A matte finish cup surface can also be employed to mitigate sticking for some products. There have been occasions (for specific products) where a matte finished punch cup provides significantly better product release than the traditional mirror finished cup surface.

In special situations or for special products, a coating may be advantageous to address sticking/picking or other tableting defects. The most popular coatings for sticky products include Hard Chrome, Chromium Nitride and Zirconium Nitride.

Formulation

Other factors can affect sticking propensity as well, including formulation moisture content, percent (%) lubricant in powder blend, compression force, and dwell time. Generally, excessive moisture or humidity in the processing area will result in an increase in sticking or picking. Also, increasing the amount of lubricant in a formulation can improve product release, but too much lubricant (most common is magnesium stearate) can negatively impact tablet compact-ability and hardness.

Process Related

Increasing compression force and dwell time are often helpful in reducing sticking and picking. Generally, increases in compression force can assist with forming a more robust tablet.

Extended head flats can be used to increase dwell time (the time the head flat spends under the pressure roll) while maintaining a given press speed (RPM), as longer dwell times generally result in a more robust tablet. Both increased compression forces and extended dwell times can help to reduce sticking as they encourage particles in the formulation to bind to one another rather than sticking to the punch face.

An overlooked cause of sticking is using a deeper than necessary fill cam. Excessive fill means a greater amount of formulation will be ejected from the die at the weight adjustment stage and recirculated back into the feeder. The feeder paddles will then essentially over blend the powder potentially creating additional fines.

Over-blending the lubricant can negate its benefit and lead to increased sticking/picking.

A Proactive Approach

Consulting with a qualified tooling vendor and discussing sticking and picking issues early in the design and development process will help reduce potential production issues.

While we’ve discussed the most common solutions for sticking and picking, it’s important to discuss all product properties with the tool vendor during the tablet design phase to help eliminate potential sticking and picking issues before they occur.