Conducting quality control analyses in-house can offer time-saving benefits and help to control costs and protect confidential information.

However, for companies that lack experience when selecting an appropriate microscope, outsourcing SEM capabilities to a university or laboratory can be a tempting option.

Here, Robbie O’Connell, Sales Account Manager (Electron Microscopy) at SEM specialist Thermo Fisher Scientific, offers advice regarding what to look for when purchasing an SEM for quality control purposes.

Electron microscopy offers unmatched capabilities when it comes to identifying material defects, assessing surface morphology and verifying material composition.

By visualising materials at the micro and nanoscale, it identifies particles, detects impurities and ensures compliance with industry standards — ultimately improving product quality.

The advantages of in-house SEM

Many companies, particularly those without a large in-house laboratory team, are often swayed towards outsourcing their SEM. Although using an external lab has its own set of benefits, bringing SEM in-house presents several compelling advantages.

One of the most significant benefits is the faster turnaround time. In-house, companies can conduct quality control analyses immediately without the delays associated with shipping externally and waiting for results.

This rapid analysis is particularly advantageous when quick decision making is critical, such as in the case of time-sensitive product releases or when immediate corrective actions are needed.

In-house SEM also offers more flexibility and greater control of the analysis process. Companies can prioritise and customise analyses according to their specific needs and adjust workflows as required.

This level of control can lead to long-term cost savings, especially if SEM analysis is a regular requirement. By eliminating outsourcing fees and relevant expenses, companies can achieve a more efficient and cost-effective quality control process.

Another key advantage of in-house SEM is the ability to maintain confidentiality as sensitive information about products or materials remains secure and protected. This is particularly important when working with proprietary or confidential materials as it minimises the risk of intellectual property (IP) exposure.

Making the leap

Before investing in an in-house SEM, companies must make a few considerations. First, it is useful to clarify why the technology is needed in the first instance.

Determining whether it is to comply with industry standards, analyse specific material characteristics or to transition from outsourcing to in-house processes will help to guide the decision and ensure that the SEM meets the company’s specific requirements.

Likewise, identifying the characteristics of the sample you want to understand will help to determine the most suitable SEM. Different systems are optimised for various sample types, whether they are organic, metallurgic or ceramic materials, for instance.

Consider factors such as sample size, conductivity and the need for additional capabilities such as energy dispersive X-ray spectroscopy (EDS) for elemental analysis.

Matching the SEM's capabilities to your sample requirements is crucial for accurate and efficient analysis.

You’ll also want to assess the level of detail you want to achieve. Consider the magnification range, resolution and imagining modes available to ensure the SEM can meet your specific analytical needs.

Ease-of-use is another consideration, particularly if this is the first time you’re purchasing a SEM to use in-house. Some SEMs are more user-friendly and require less specialised training, making them ideal for environments in which multiple users will operate the instrumentation.

The right SEM partner

A good SEM partner can offer you the tools and support needed to ensure that your investment meets both your current and future analytical requirements. They should be able to offer a range of products that fit different budget levels and performance needs … whether it’s a desktop solution or a larger standalone model.

Thermo Fisher Scientific offers SEM solutions that meet a diverse range of customer needs. Our experts can work with your business to recommend a SEM based on your performance, budget and technology requirements and can provide ongoing training and equipment servicing.

For instance, the Apreo ChemiSEM is specifically designed to pose much smaller demands on its users.

Featuring an optics system that aligns itself, as well as an automated image fine-tuning process, users new to electron microscopy can access high-end in-house performance without needing to outsource to an external lab.

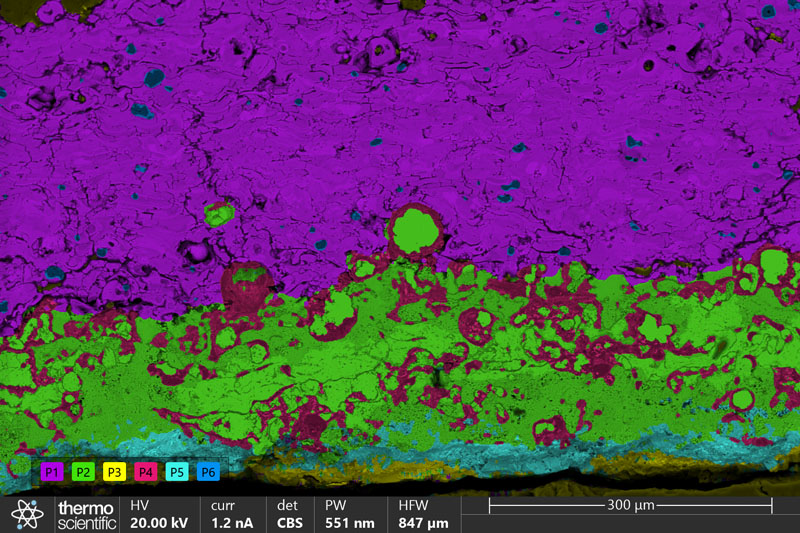

Moreover, with Thermo Fisher Scientific’s ChemiSEM technology integrated into the microscope’s user interface, SEM, EDS and electron backscatter diffraction (EBSD) can be obtained in a single seamless workflow.

This means that, while high-resolution imaging delivers topographical, surface and compositional information, EDS and EBSD analysis delivers both the chemical composition and crystallographic characterisation of an observed specimen.

This instantaneous access to elemental and structural data is available while the user is imaging their sample, thus providing a streamlined way to conduct thorough materials analyses in one place.

Bringing SEM in-house reaps many benefits. Although for some this may mark a step into unknown territory, choosing the right SEM partner can make the technology accessible for all who want to better understand their materials.

Ultimately, choosing a partner that can tailor solutions and offer a scalable and user-friendly approach means that SEM analyses can be performed with confidence.