Selecting the best construction material is an important element of plant design. For powder handling applications, choosing a surface finish that promotes smooth, controlled flow through the process is key to trouble-free production and will enhance operability over the long term. So one of the first tasks for production and packaging machine manufacturer Harro Hoefliger when developing capsule filling equipment is to determine the most appropriate materials of construction and surface finish. The FT4 powder tester from Freeman Technology, with its ability to generate sensitive wall friction angle data, is being used in support of this task.

Harro Hoefliger is a major supplier of flexible production and packaging machines tailored to the specifications of the pharmaceutical industry. Dosing requirements for pharmaceuticals are highly demanding, often requiring the extraction of a small, single dose from a powder bulk. Oral capsules typically have a fill weight in the range 50 to 500mg but dry powder inhaler (DPI) applications are now increasingly common. This technology requires the filling of capsules or blisterpacks with much smaller doses of 0.5 to 15mg. Furthermore, processing powders for inhalation can be especially challenging because to minimise any deposition of unnecessary material in the lung they generally do not contain additives, such as magnesium stearate, used to improve the properties of oral formulations. DPI formulations tend, therefore, to be "sticky" with a pronounced tendency to adhere to hoppers, slides and/or the dosing system itself.

characterising friction

The inability of existing methods to differentiate between different construction materials in terms of their relevance for processing DPI formulations has encouraged Harro Hoefliger to investigate new techniques for characterising the friction between a surface finish and formulation. Tests suggest that the FT4 is a good choice for this application since it provides wall friction angle (WFA) data that sensitively differentiate between alternative materials of construction/ surface finishes.

An examination of the different techniques that are used for capsule filling illustrates the demands of the process in terms of powder flow and defines certain targets in selecting an optimal material of construction.

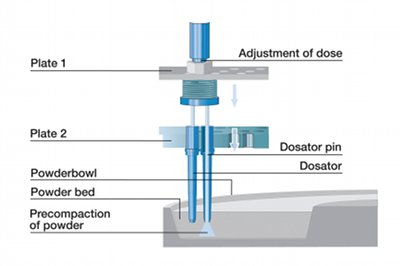

A frequently employed method for capsule filling is the rotating dosing plate and tamping pin (see Fig. 1). The dosing plate has a number of holes drilled through it, which for most of the time remain closed off by the tamping plate. As the dosing plate rotates below the powder bed, material flows into each hole, the tamping pins successively compressing the powder to a closely controlled depth. The equipment is somewhat analogous to a tablet press although the compression forces used are much lower.

After several "filling cycles" the compacted powder plug is ejected through the dosing plate into the capsule shell. Smooth and complete ejection of the powder plug is critical to ensure dosing consistency. Furthermore, any powder that adheres to the machine surfaces can create operating problems. Residual powder on the sides of the holes or where the plates rotate against each other will inhibit the action of the machine and cause wear.

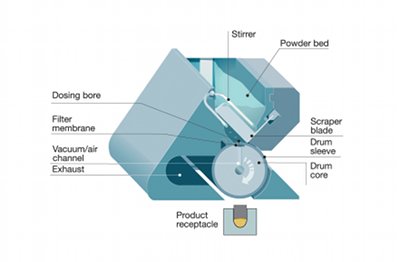

With a dosator and pin system (Fig. 2) the dosator is plunged into a loosely packed powder bed, filling through the open end. A pin inside the dosator compresses the extracted dose, which is subsequently ejected into the capsule shell. Here, there is a clear balance to be struck with respect to the frictional force between the powder and dosator surface. Powder must flow easily into the tube as it is pushed into the powder bed, otherwise filling will be incomplete. Low friction between the dosator surface and the formulation will make this easier but will also hold the powder less securely during transfer, necessitating use of relatively high compression forces to produce a more stable plug.

Fig. 2: Dosator and pin capsule filling process

A vacuum drum filling system (Fig. 3) presents somewhat similar challenges. Here powder is transferred from a hopper, under vacuum, into a port in which it is held as the drum rotates. A scraper or doctor blade passes over the surface of the rotating drum, removing any excess powder. Once the port is directly above the capsule or vial the powder plug is ejected using positive pressure. Low friction between the drum surface and powder will once again assist with filling (and also emptying) of the port, potentially affecting the strength of both the vacuum and positive pressure required for effective processing. It will also reduce the tendency for material to adhere to the surface of the drum as the excess powder is scraped away.

Fig. 3: Schematic of a vacuum filling process

In summary, for each of these dosing techniques the friction between the powder and the material of construction or surface finish influences processing behaviour. Choosing the right material will enhance dose consistency and/or reduce the severity of processing conditions. Equipment manufacturers therefore rely on information that supports this choice.

To assess the likely success of a given construction material, Harro Hoefliger engineers use a simple test whereby a sample of powder is sandwiched between two discs of the proposed material. The discs are rotated relative to one another and then separated and held upright. From a subjective assessment of how much material remains adhered to the discs, the system is scored from one to six. Six denotes a relatively adhesive powder and one indicates a powder that falls easily from the discs leaving a clean surface.

The test is attractively simple and offers helpful guidance as to the best material choice. Different surface finishes can be ranked in the same way for any given powder. Unfortunately, the technique fails to be clearly differentiating with formulations for DPIs, resulting in a classification of five or six, whatever the surface finish. A more sensitive descriptor of the degree of friction between powder and surface is required.

quantifying friction

Wall friction angle (WFA) is a parameter used to quantify the level of friction between a construction material and powder, most commonly in connection with the specification of hoppers using the methods developed by Jenike.1 The amount of WFA data in the open literature is limited but there have been studies investigating links between this variable and capsule filling performance. Work by Joliffe and Newton2 examines the impact on dosing of re-surfacing the bore of a dosator, to create different surface roughness. One of their conclusions is that for the dosator and piston system studied there is a correlation between WFA and process behaviour that supports "the concept of an optimum wall friction angle for powder retention (and hence uniformity of fill weight) with minimum stress".

The technique for measuring WFA involves shearing a powder bed against a disc of the proposed construction material. The core methodology3 has remained unchanged for decades but measurement precision and reproducibility have advanced considerably as a result of improved sample preparation, greater equipment sensitivity and fully automated test routines. With modern instruments WFA can be determined with a high degree of confidence even for low friction materials.

WFA determination involves measurement of rotational torque, as the sample is sheared under the application of a known normal stress, an applied force in the vertical axis. Modern instruments can control and record these stresses with exemplary precision, down to low values, in order to give more reliable data. The most sophisticated, such as the FT4 universal powder tester, also incorporate a conditioning step prior to measurement: gentle agitation of the sample in a prescribed way. Conditioning leaves a consistent, loosely packed powder bed, largely eliminating the impact of processing history and establishing a baseline state for measurement. This significantly improves reproducibility.

The following study of 15 different materials demonstrates the ability of the FT4 to measure even very small WFA values (low friction systems) and to differentiate sensitively between alternative materials of construction or surface finishes in tests with an inhalation grade lactose.

The WFA of a range of different materials of construction and surface finishes was measured using a single powder, Respitose ML001, a commercially available, inhalation grade lactose with a broad particle size distribution, low to moderate cohesivity and high compressibility. The materials of construction and surface finishes selected are all ones used in pharmaceutical processing plant.

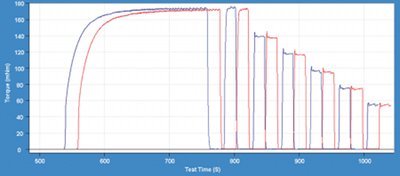

Figure 4 shows raw data from the testing process. Initially pre-shear is applied to a consolidated powder sample to reach a pre-shear steady state condition. Once this is achieved, rotation is stopped and the normal force reduced in preparation for the first measurement. Rotation re-starts and the shear stress increases until it reaches a maximum value. Rotation then stops once more to allow further reduction of the normal force in preparation for the next measurement. This process is repeated at several levels of consolidating stress.

Fig. 4: Raw data from WFA measurement showing the initial build-up of shear stress to a steady state condition and data for all following tests at reduced normal stresses

The raw data build a plot of shear stress versus normal stress, from which the wall friction yield locus is constructed and the WFA determined.

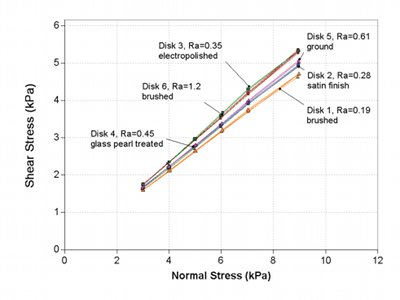

Fig. 5: Shear stress vs. normal stress data for stainless steel showing the impact of surface roughness on the level of friction between the powder and metal (surface friction is quantified by Ra, a higher Ra value equating to a rougher surface)

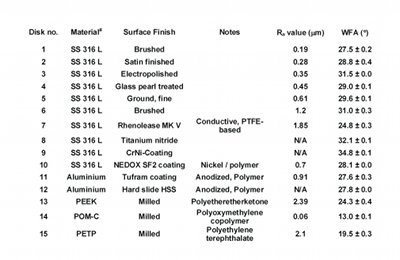

For this study, the complete test cycle was repeated two to four times for each material to assess reproducibility and create the database shown in Table 1.

Table 1

Within the resulting dataset reproducibility is excellent, and there is clear differentiation between the materials. Chromium-Nickel-plated 316L stainless steel presents the greatest frictional resistance and milled polyoxy-methylene copolymer the least.

Taking the stainless steel results as a group, WFA generally increases with surface roughness, as might be expected. The anomalous result for electropolishing is interesting, and significant, as the technique is commonly used to try to improve powder flow. For this particular lactose it appears that electropolishing is unlikely to have a beneficial effect.

Analysis of the different polymeric samples as a separate discrete group shows a similar relationship, higher surface roughness giving rise to higher WFA values. However, all the polymeric materials give a lower friction than the stainless steel samples despite having, on the whole, higher surface roughness. This indicates there is no universally applicable relationship between WFA and surface roughness as quantified by Ra, suggesting that other factors must also influence frictional resistance.

This observation echoes the findings of Joliffe and Newton, who concluded that where surfaces are produced using different preparation techniques Ra values alone may not provide sufficient characterisation information to rationalise trends in WFA.2 In the current study, all the discs were circumferentially finished, eliminating the possibility of any directional effect of surface textures. Meticulous cleaning and the consistency of data from the first measurement on a brand new disc make it extremely unlikely that the results are skewed by fines "filling" the textured surface. Here then it seems possible that the differences between the polymer and metal results are attributable to effects such as electrostatics or some form of surface interaction between the powder and construction material.

In conclusion, quantifying the degree of friction between a powder and proposed material of construction or surface finish assists with design, helping to ensure in-built compatibility between the powder and processing equipment. Modern powder testers measure WFA, a descriptor of friction, with precision and sensitivity, making them a highly differentiating tool for equipment manufacturers.

For Harro Hoefliger, a key goal is to learn how to characterise powder-construction material systems in a way that relates to capsule filling and dosing, especially for DPI formulations. The results presented highlight the potential of WFA measurements within this context. Quantifying WFA provides information that can be used to guide the specification, for example, of the surface finish of a dosator or of a rotating disc, and to ensure more consistent dosing.

For equipment manufacturers, building a database of WFA values and correlating with performance develops the knowledge required more successfully to specify an optimal surface finish for a given piece of plant.

References

1 A. W. Jenike, University of Utah, Storage and flow of solids, Bulletin 123 of the Utah Engineering Experiment Station, November 1964 (Revised 1980)

2 I. G. Joliffe and J. M. Newton J. Pharm Pharmacol 1983 35 pages 7-11

3 Standard Shear Testing Technique for particulate solids using the Jenike Shear cell. IChemE/EFCE, 198