Forward-looking production technologies rely on process intensification and the efficient use of time, energy and raw materials, reports Hans-Joachim Jacob, Senior Expert, Process and Applications, at ystral.

When mixing and dispersing ingredients with optimised processes, the differences in terms of required energy, volume-specific capacity or newly created phase boundaries compared with conventional technologies such as agitators, injectors or high-speed dissolvers are significant.

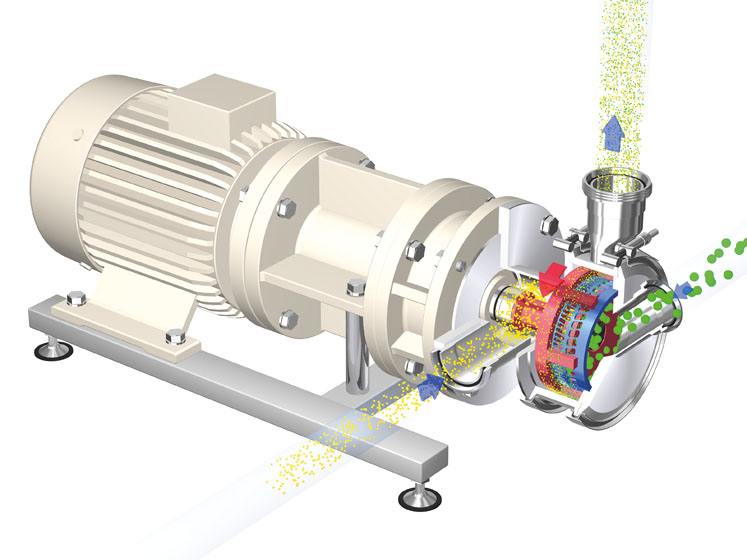

With the YSTRAL Conti-TDS disperser, for example, which is operated outside of the vessel, the processes of wetting and dispersing are concentrated in one zone — with an effective volume of approx. 0.25 L.

Compared with a high-speed dissolver (HSD), operated inside the vessel, the disperser generates 30,000 times more volume-specific power. This concentrated power is crucial for successful dispersion.

Using a rotor-stator system, the Conti-TDS also builds up shear forces that are a thousand times higher. The dwell time is extremely short, so that only a fraction of the energy is needed compared with an HSD.

Pollution-free process control

New findings with regard to health hazards when handling powders and liquids, more rigorous specifications concerning occupational safety, growing hygiene demands and, last but not least, the use of sensitive electronics increasingly make process control that is free from dust, gas and fumes a must-have.

For mixtures of dust and fumes, for instance, conventional technologies cannot rule out health hazards for the operator — as the powder materials are added to the liquid surface in the vessel in an open process.

Health hazards and risks can be avoided with powder induction systems in which the powders are not added to the liquid surface from the top in an open vessel … but are inducted directly into the liquid in a dust-free manner.

Less or fewer biocides

Manufacturers in very different industries have tasked themselves with reducing — or completely avoiding — biocides in their products. This is mainly handling biocides can be problematic or because they are accompanied by undesirable effects in the end product.

Giving up the use of biocides is possible if the item in the production process is not contaminated with germs — particularly those from the ambient air.

With ystral processes, powder and liquid components are added in a closed circuit. The interior of the process vessel is sealed off against the ambient air by means of sterile filters.

Flexible modularisation in process technology

In light of differing requirements, variable batch sizes and ever more frequent product changes, a flexible machine and plant design is becoming increasingly important. Manufacturers must be able to produce a large number of product versions and newly developed products to order.

Whereas machines with a rigid design must be replaced completely in case of a process change, selective adaptations can be achieved with modular systems.

With systems from ystral, physical/control modules can be flexibly combined and/or adapted and extended in accordance with the current requirements. On machine level, ystral uses conversion sets consisting of few parts to adapt a universal basic machine to meet new needs.

Twin tank versus single tank

A twin tank plant is suited to continuous processing: while production takes place in one vessel, the finished product is pumped out in the second one. As soon as this vessel is empty, the switch occurs.

But the twin tank principle is also used at ystral to increase plant capacity; the YSTRAL Conti-TDS disperser is only used for powder induction and dispersing, but is not required for other process steps such as rinsing, filling and pumping out.

Owing to the alternating use of the Conti-TDS on two identical process vessels, machine downtime can be minimised. With the twin tank concept, ystral achieves increased system efficiencies by up to 100% with minimum additional space requirement.

Only a second identical process vessel, which is connected to the disperser by a pipe, is required with the Jetstream Mixer.

Trends don’t always point in one direction

The changes in process technology are varied. For certain applications or industries such as the pharmaceutical industry, a key driver is reduced batch sizes; other industries are focusing on larger output quantities and continuous inline processes.

Independent of this, future solutions in terms of process technology that enable decreased production costs, shorter production times, improved plant efficiency, lower energy consumption and more efficient use of raw materials will prevail.

ystral.com.