Introduction

Scaling up a pharmaceutical film-coating process can be very challenging due to many factors such as product/process complexity, absence of proper pilot and production size equipment, limited availability of ingredients (particularly active ingredients), and costs. Different approaches have been proposed, some representing simple and straightforward practical approaches. Keeping the amount of dispersion applied to a single core when it passes through the spray pattern constant (Figure 1) proved to be the most reliable concept. It was demonstrated that by maintaining the ratio of spray rate and inlet air quantity, as well as the spray rate per nozzle and the circumferential drum speed constant, comparable results at different scales could be achieved.

Objective

The aim of this work was to investigate the possibility of managing an up-scaling process using the same drum/equipment set-up for both small- and large-scale batches, bypassing the need for different coater facilities. An innovative approach is proposed to process different batch sizes in the same pan. With successful implementation, pilot-scale equipment would not be mandatory for a scale-up procedure, addressing a pressing need for many pharmaceutical companies that do not have both installations.

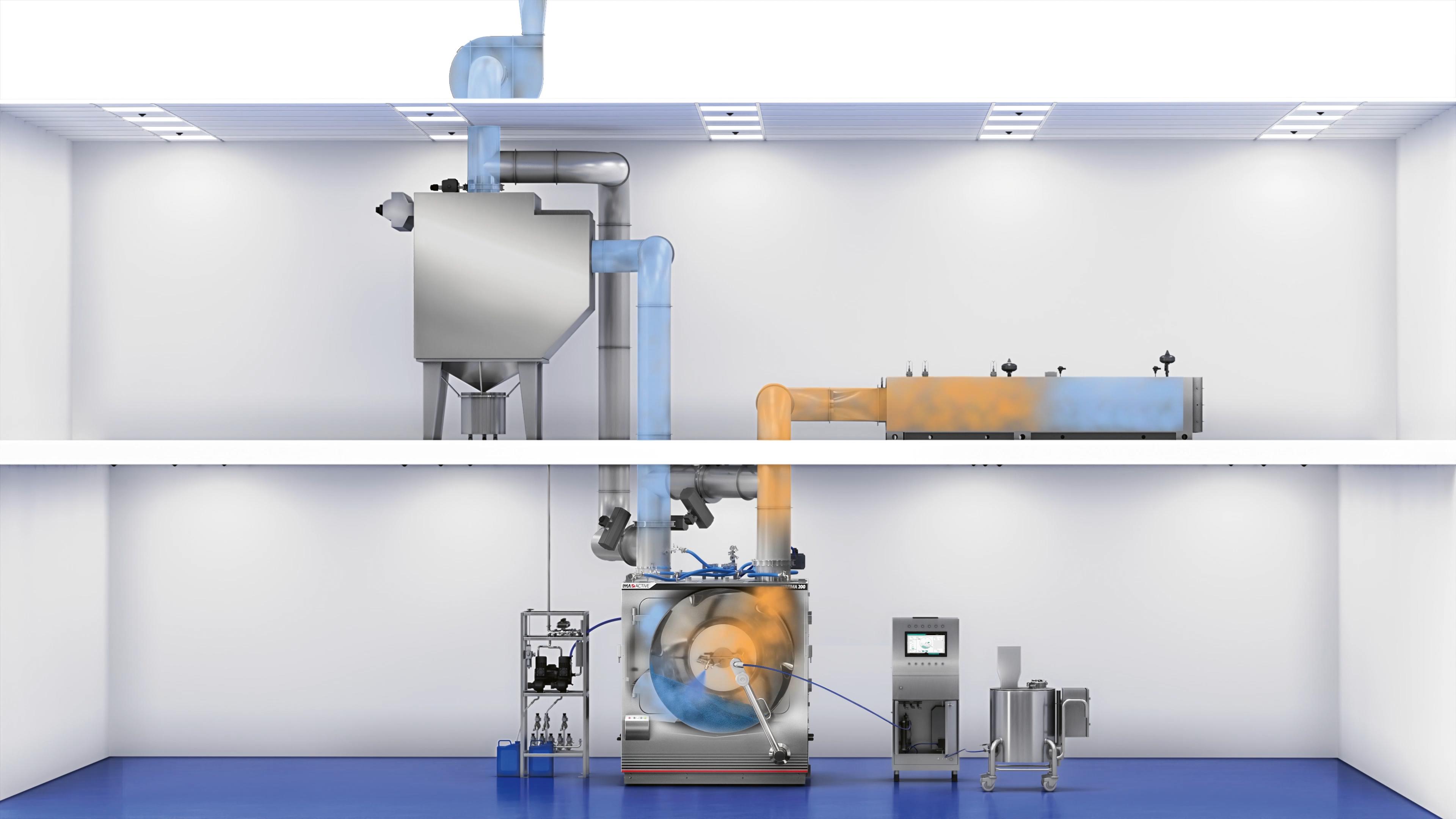

Figure 1: Perfima set up.

Experimental materials

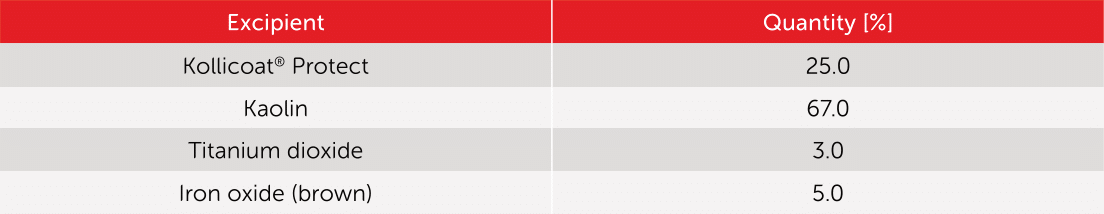

Kollicoat® Protect is a combination of Kollicoat® IR and polyvinyl alcohol in a 6:4 ratio. Due to its excellent properties, it can be used as a film former for effective moisture-protective instant release coatings. Table 1 shows the formulation tested.

Equipment

Side-vented pan coater Perfima 200 (IMA, Italy).

Methods

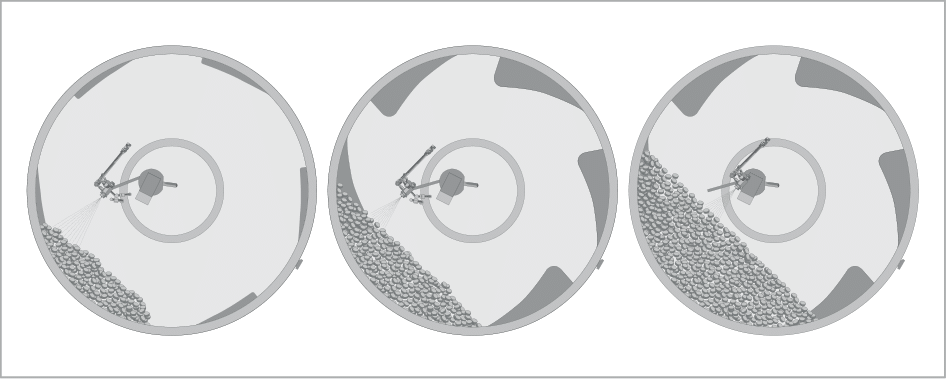

The side-vented pan coater Perfima 200 was used for the investigation. A moisture-protective film-coating formulation based on Kollicoat® Protect was employed to investigate the coating and up-scaling characteristics of three incremental batches, providing 35, 75, and 136 kg loads respectively. Considering the tablets' density of 0.75 kg/L, the corresponding filling volumes were 47, 100, and 181 L, representing 19%, 40%, and 72% respectively. In contrast to other types of equipment, the positioning of the baffles on the perforated area of the Perfima 200 allows effective mixing even of small batches from 10% to 100% of total capacity. Therefore, batch sizes from 25 to 250 L can be coated in one coater without interchanging the drum (Figure 2).

Figure 2: Perfima 200 (250 L) pan fillings.

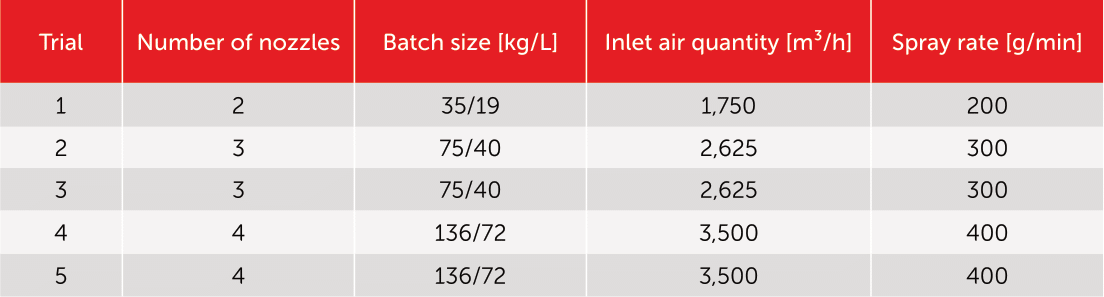

The optimal circumferential drum speed was found as a first step for the 35 kg batch and then kept constant for the other batch sizes. Since using the same drum size/geometry and a constant peripheral speed, it can be assumed that the tablet speed in the spray pattern remains constant regardless of batch size. The same drum speed was used in all trials, and the number of nozzles was changed to adapt to the batch volume. The fact that drying efficiency depends on the ratio between the overall spray rate and the amount of process air can be used for scaling up by keeping the inlet air quantity and the spray rate per nozzle constant (Table 2).

Table 2: tested parameters at constant spray rate per nozzle and pan speed.

Results

The number of nozzles was chosen to mimic a pilot lab coater, even though all the filling ranges can be worked using four nozzles due to pan geometry. An optimal inlet air quantity of 875 m³/h per nozzle (overall 3500 m³/h) was found experimentally and combined with a spray rate of 100 g/min per nozzle. Nozzle diameter and atomization/pattern pressure were kept constant during all trials to maintain consistent tablet humidity exposure. In all trials, the following parameters were kept constant:

- 24 cm gun distance

- 2.5 bar atomization pressure

- 2 bar pattern pressure

- 60-65°C inlet air temperature

Final coating quality achieved in the different trials was comparable, as were parameters like exhaust air humidity.

Discussion

The Perfima 200 enabled the operator to process a huge variety of batch sizes in one type of equipment, without requiring any equipment modifications (e.g., drum exchange). The perforated standard drum provides a workable range between 10% and 100% of maximum capacity, a feature that allowed the evaluation of the up-scaling properties of a film-coating formulation in just one piece of equipment (Figure 3). Three different batch sizes and relative appropriate numbers of nozzles were used to predict the up-scaling characteristics. The air flow rate was calculated for the small-scale batches after a theoretical estimation of the final production batch size. The maximum dispersion flow rate in small scale was determined to predict the maximum humidity exposure for tablets. Using this value, the settings for the different batch sizes and numbers of nozzles were calculated and tested. The results confirmed that both predictability and processability were provided over the range of batch sizes.

Figure 3: Perfima 200 pan filling 10-100%.

Conclusions

- Independent of scale, the ratio of spray rate to inlet air volume is responsible for the surface quality.

- The Perfima 200 is a very flexible coater system enabling a broad range of batch sizes (10-100% drum filling).

- Kollicoat® Protect formulations can be used with a very low polymer content of just 25% in both pilot and production scales. This enables formulations offering the highest protective properties against ambient moisture.

- The prediction of the up-scaling procedure required the evaluation of the amount of film-coating dispersion that could be applied onto a single core when it passes the spray pattern. By relating the spray rate to the respective drying capacity (inlet-air quantity), general process settings could be defined for the formulation.

- Keeping these settings constant throughout the up-scaling process led to the same product quality, independent of batch size.

References

[1] Cech T., Wildschek F., Scale-Up of Film Coating Processes, “ExcipientFest Europe”, Cork, Ireland,

June 17-18, 2008.

[2] Cech T., Kolter K., Developing an Instant Release Moisture Protective Coating Formulation

based on Kollicoat® Protect as Film Forming Polymer, “PBP World Meeting”, 2008.