The Divisions of IMA Group and its specialists will be delighted to introduce you our latest and innovative technologies for the processing and packaging not only for the pharmaceutical, biomedical and nutraceutical products but also in the personal care, homecare and toiletry sectors.

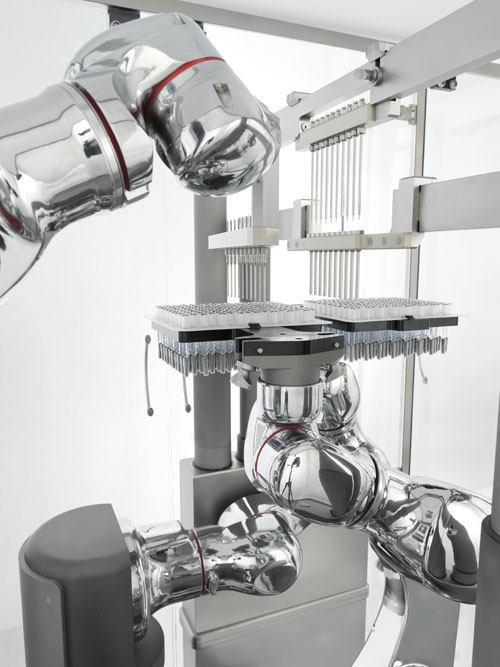

IMA Life, the Aseptic Processing & Freeze-Drying Solutions division, will present on show INJECTA 36, advanced robotic fill-finish solution which raises the bar for the high-speed processing of Ready-To-Use syringes.

Recently awarded as Best in Show Award at Interphex NY 2023, INJECTA 36 introduces an innovative solution for 100% In-Process Control and check-weighing, and it is further proof of the key role played by IMA Life in the Ready-To-Use segment for automatic filling & closing machines, able to maximise production performance.

In this CPHI edition, a dedicated Continuous Manufacturing corner powered by IMA Active is also on display.

Through advanced process control, this technology enhances the potency, effectiveness, and safety of pharmaceutical products. IMA Active’s belief in and knowledge of Continuous Manufacturing have grown stronger thanks to intensive R&D work carried out on two fronts.

Omas Tecnosistemi is the recent acquisition by IMA, specialised in the design and manufacturing of machines and complete processing, filling and capping lines for liquids, creams, hot creams, and powder products in bottles, jar and tubes.

Omas will show the GD-250 double pitch filling and capping machine, the CX-50 turbo emulsifier mixer and the DEP-MI Powder Filler, all suitable for installation in the Personal Care and Health Care sectors.

Many sustainable packaging solutions will be showcased and our experts will be there to illustrate more about the Group’s concrete and ecofriendly developments. IMA Safe and IMA EOL will be introducing the new frontier of pharma green packaging and applications in terms of recyclable and biodegradable films, sustainable plastic materials and paper - just to name a few.

IMA MED-TECH, the new business unit powered by IMA AUTOMATION, will be also present on show with its experts, ensuring insights about the most recently developed assembly solutions for medical technologies, such as drug delivery injectors, inhalers, in vitro diagnostics and point-of-care, wearables, tubing sets, surgical instruments, pharma caps and, last but not least, complete processing and packaging lines for contact lenses.

IMA Pharma: the all-in-one supplier

IMA Pharma is composed of highly expert divisions able to offer tailor-made solutions for the most sophisticated requests of the pharmaceutical market: IMA Active (Solid Dose Solutions), IMA Life (Aseptic Processing & Freeze Drying Solutions), IMA Safe (Packaging Solutions), IMA EOL (End of Line Solutions) and IMA MED-TECH (Technologies for Medical Devices).

Together, they combine unique skills and knowledge where people, equipment and technology come in perfect synergy.

IMA Active offers a complete range of machines for the processing of oral solid dosage forms: granulation equipment, tableting machines, capsule filling machines with a wide range of filling and control systems, capsule and tablet coating machines in perforated pan and solid wall, capsule and tablet weighing machines, product handling and washing systems.

After years of study and observation, IMA Active has also taken steps towards continuous manufacturing, revolutionising the future of pharmaceutical technologies for OSD forms.

In May 2021, IMA finalized the acquisition of the American Company Thomas Engineering (now Thomas Processing), leader in the coating sector from over 50 years. Thomas Processing aims to become the overseas Center of Excellence for coating under the auspices of IMA Active.

IMA Life, which includes the production sites of IMA Life Calenzano, IMA Life Pharmasiena, IMA Life North America, IMA Life Beijing and IMA Life Shanghai, offers a comprehensive product portfolio to process liquids and powders in aseptic and non-aseptic environments:

- vial and ampoule washers

- depyrogenating tunnels

- filling and closing machines for vials, ampoules, cartridges and Ready-To-Use components

- powder microdosing and macrodosing machines

- cappers

- containment solutions, including Restricted Area Barrier Systems and isolators,

- lyophilisation process developments

- continuous aseptic spray freeze drying technology

- industrial, pilot and laboratory freeze dryers

- automatic and semi-automatic vial loading and unloading systems for freeze dryers.

Last but not least, assembly and labelling machines for syringes, labelling machines for vials, ampoules, shaped containers, Blow-Fill-Seal single-dose containers and cartons with the latest serialization systems.

Blowing machines, depackers, tray loaders and other ancillary equipment are also available.

IMA Safe, which includes IMA Safe Swiftpack, IMA North America (IMA Safe Nova), IMA Safe Comadis, Omas Tecnosistemi, IMA Sarong, IMA Safe PG and Perfect Pack, specialises in designing and manufacturing complete lines for primary and secondary packaging in the pharmaceutical, nutraceutical and cosmetic industries.

The IMA Safe division offers a comprehensive range of machines for blister packaging, capsule and tablet counting, sachet and stick packaging, tube, bottle and jar filling and capping, as well as machines for suppositories, ovules, and liquid unit dose form, fill and seal applications, and cartoners.

IMA END-OF-LINE HUB is a unique solution provider of secondary packaging technologies. Each company within the hub brings a specific expertise.

IMA BFB is a leading brand in end-of-line technologies ranging from robotic handling to overwrapping, case packing and palletizing.

IMA Ciemme is an expert manufacturer of forming, loading and automatic closing technologies. IMA Mespic specialises in tailor-made solutions, from case packers to palletisers.

IMA Phoenix is a leading manufacturer of print&apply and modular labellers for self-adhesive labels.

IMA AUTOMATION designs and manufactures advanced technological systems for the handling and assembly of a variety of components for diverse applications and in different sectors: automotive, E-mobility, electrical motors, medical devices, caps & closures, eye care, electro-mechanics and watchmaking.