Mini tabs are transforming the way that healthcare professionals can administer medicines. From paediatrics to people with difficulty swallowing, they make life easier and improve compliance. They are also opening up personalised medicine, making it simpler to combine multiple drugs and varied doses in a single capsule. In trials and full-scale manufacturing, weight checking is as important for mini tabs as any other form. However, with their much smaller size they present serious challenges:

- Because mini tabs are much smaller, your quality checks need to be sensitive to very slight differences in weight.

- The much greater ratio of surface area to weight means mini tabs are more friable and prone to chipping, so weight checking needs to be accurate and robust.

- With their low weight, they suffer more from the effects of static, including sticking together and to machinery.

- Their very small size means that manual handling is almost impossible, so even small batches for trials or QC need to be handled differently.

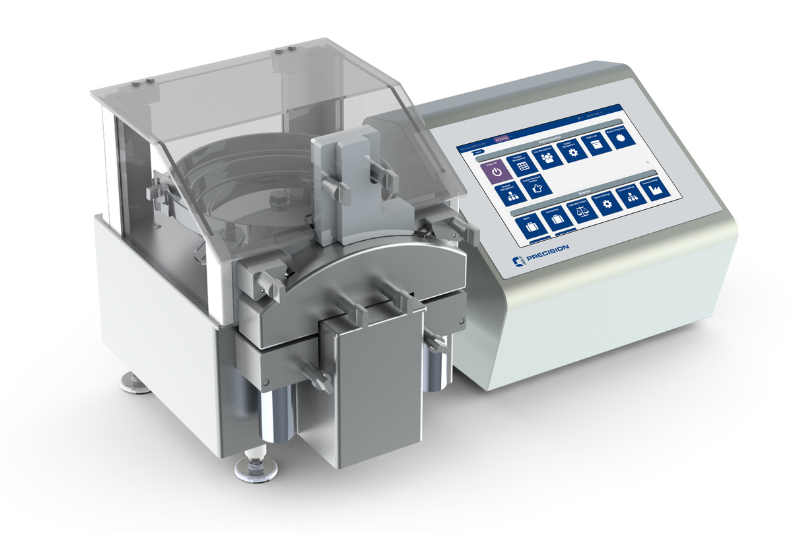

Pharmaceutical research organisations and manufacturers worldwide have found the solution with CI Precision. Our precision weight sorters are being used to accurately weight check batches of mini tabs for clinical trials and for quality control. Our weight sorters can be six times more accurate than standard pharma checkweighers, more than sufficient for the demands of weight checking mini tabs. CI Precision weight sorters carefully separate out individual doses and have no problem with damaged product or dust. They also manage static build-up, so even the smallest, lightest doses pass smoothly through the process. If you would like to find out more about weight checking and weight sorting mini-tabs and other challenging dose forms, please visit https://www.ciprecision.com/mini-tabs/ or contact us.