Often, between-lab transfers can involve instruments from different vendors or with different configurations, adding multiple variables that can affect the method and subsequent results obtained. Moreover, replacing legacy instruments with modern counterparts can also raise inconsistencies in the workflow.

In pharmaceutical companies, successful method transfer is essential for strong quality assurance and quality control (QA/QC) practices during sample analysis … and to comply with regulatory requirements. Here, we highlight the common challenges faced by chromatographers when transferring liquid chromatography (LC) methods and discuss how new analytical technologies are helping laboratories to overcome these challenges.

Challenges of analytical method transfers

Transferring analytical methods, a common challenge faced by regulated laboratories, requires maintaining consistency and reproducibility across various scenarios. To develop an entire LC workflow, several instruments within the same laboratory need to operate in seamless co-ordination.

In such intra-lab method transfers, the difficulty lies in the systematic integration between different instruments within a workflow and is often crucial when legacy instruments get swapped out for new, modern counterparts.

By contrast, methods originally developed by one department (analytical development, for example) may need to be transferred to and implemented by another department, such as a QC laboratory. In another case, projects that are conceived and outlined internally can get outsourced to a contract organisation where it is finally completed.

Such inter-lab transfers, where the transferring and receiving laboratories may have instruments from multiple vendors, will require consistency across individual steps in the experimental workflow and instrumental settings.

Regardless of the reason, the overall goal of a successful method transfer is that the receiving laboratory, despite the variables in instrumentation, must still be able to get the same results as the transferring laboratory — within acceptable experimental error margins. Successful instrument-to-instrument method transfers in LC workflows depend on multiple factors.

Robustness of the method to be transferred: Are the results reproducible, even with slight variations in experimental conditions? Robust analytical methods are typically capable of generating consistent data by factoring in the potential variability of the process.

Setting defined acceptance criteria with process limits ensures that deviations are easily flagged for further investigation. Ideally, the method parameters will be in a robust zone where minor external influences will not impact the end result.

Dependence on technical expertise: Is the method easy to execute by users with varied technical skills? Procedures that involve subjective interpretation or making individual judgements are more challenging to transfer across laboratories.

Setting strict parameters and providing clear user instruction in the form of a detailed procedure can help to ensure that high-quality results are obtained independent of skill level. For efficient method transfers, participating laboratories will need to document procedures with enough detail and eliminate all ambiguities such that there is only one possible interpretation of the data.

Instrument characteristics: All LC instruments are typically built on similar operating principles. However, the unique instrument characteristics provided by each manufacturer may bring noticeable variability in performance.

Even when laboratories host instruments from the same vendor, having mismatched models or using old versus new versions can generate inconsistencies. Settings or features built into an instrument can also cause adverse effects on data reproducibility.

For example, injectors can vary in the way the sample is transferred to the separation column or pumps can deliver solvents by either high pressure or low pressure mixing. The gradient delay volume or dwell volume within an LC system can impact the retention times of a gradient separation, affecting early eluting compounds.

Extra-column volume from the injector to the detector, again a variable between LC systems, can broaden the peak, affecting separation efficiencies. With a majority of analytical methods requiring that LC columns are thermostatically controlled, the accuracy and precision of the set temperatures of the column heater can vary across LC systems.

In addition, the operation of how the heat is dissipated from the column (circulated or still air) can directly impact the separation of analytes.

In general, chromatographers typically face three types of data-related challenges caused by underlying instrumental factors during method transfer:

- When retention times don’t match between the transferring and receiving laboratories: this issue can be caused by differences in pumping mechanisms, uneven gradient delay volumes or inconsistent column heating

- Bad peak shape or loss of resolution: this may arise owing to differences in detector settings, extra-column dispersion effects or thermal mismatches

- Lower signal to noise ratio: noise can be increased as a result of incorrect detector settings or the signal can be reduced because of inequivalent light paths.

Multiple variables arising from the method itself, along with the other significant factors attributed to instrument characteristics, can negatively impact QA/QC output. Failure to obtain consistent data by the receiving laboratory will ultimately result in a time-consuming revalidation step, thereby increasing costs and reducing efficiency.

Simplifying method transfers with modern LC technologies

To avoid cumbersome revalidation efforts, laboratories will need to carefully control the many parameters that improve the success rate of a method transfer.

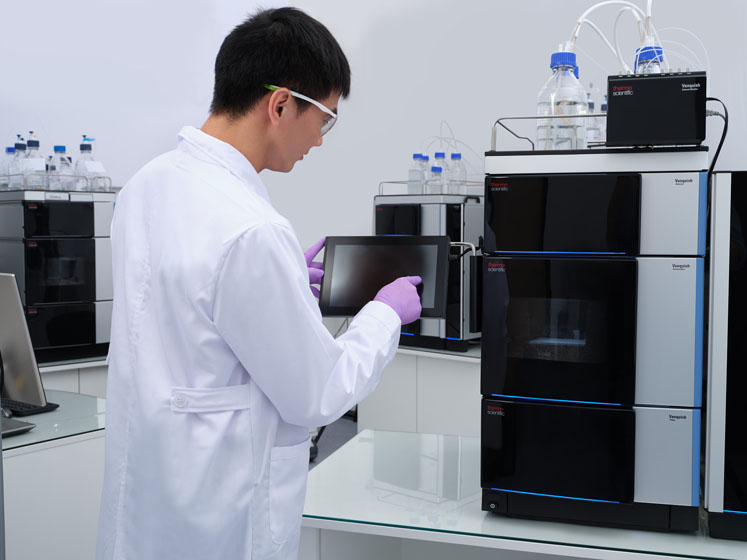

Whether transferring methods between similar or different instruments, modern LC systems, such as the Thermo Scientific Vanquish Core High Performance Liquid Chromatography (HPLC) System, provides seamless method transfers and the precise replication of legacy LC methods, even across vendors.

These LC systems address the key parameters of successful method transfer with novel features that enable users to adjust gradient delay volume, minimise system dispersion differences and match column thermostat modes.

Equivalent chromatographic transfer across instruments directly depends on the unique hardware of the system. For instance, in the Vanquish Core HPLC systems, users can fine-tune the gradient delay volume to match retention times by adjusting the idle volume in the autosampler metering device, as well as delay injection settings to ensure timely peak elution.

To maintain column and eluent temperatures that mimic thermal conditions used in the transferring laboratory instrument, users can also use the column’s thermostat features as well as control the column preheater and fan speed, which will help to replicate the behaviour of the system the method originated on.

To meet a wide range of project needs, contract organisations are often equipped with a diverse collection of analytical systems. At Patheon, a contract development and manufacturing organisation (CDMO), for example, one of their method transfer challenges involved seamlessly integrating new ultra-high performance liquid chromatography (UHPLC) systems with existing analytical systems manufactured by different vendors.

Using the platform architecture of the Vanquish UHPLC system, specifically designed with novel features to simplify method transfers, the team successfully streamlined the process by making informed adjustments.

The analytical scientists at Patheon resolved inconsistencies associated with instrument-to-instrument transfer using the following features on their new UHPLC platform:

- active solvent preheating helped to maintain thermal consistency from one instrument to another as their facility carried systems from multiple vendors

- multiple column heating modes enabled users to emulate the thermal environment from another vendor’s LC system to match how heat was dissipated from the column; this minimised the variability in protocols originally developed on their ageing fleet of LC systems

- the built-in adjustable gradient delay volume feature allowed for fine-tuning volume adjustments without altering the gradient table; in case of volume differences between two systems, the injection can be decoupled from the start of the gradient separation

- column heaters that can accommodate columns up to 30 cm in length ensured that both legacy HPLC methods and recently developed UHPLC methods remain supported simultaneously, eliminating any interruption to the workflow.

Features, such as the SmartInject technology, incorporated into the Vanquish LC systems, eliminate the pressure dip that typically occurs during injection, yielding precise retention times upon method transfer as well as extending the lifetime of LC columns.

An important consideration for LC method transfers, especially in the pharmaceutical industry, is the thermal gradient created within the column by viscous heating. These gradients, if not controlled, can adversely impact the peak shape and retention time of analytes.

Modern LC systems offer a dual mode thermostatting, allowing users to choose the most appropriate way to maintain thermal conditions. For instance, the forced air thermostatting mode results in a radial temperature gradient wherein the heat is more concentrated in the centre of the column; the still air mode offers an axial temperature gradient such that the heat gradually increases along the column length.

Having multiple options to maintain temperatures inside the column supports method transfers from a wide range of instruments across numerous protocols.

Conclusion

Successful method transfer, an integral step in pharmaceutical product development and testing, depends on many variables ranging from system characteristics, instrument configuration, method robustness and operator-to-operator variability, to name a few.

Designing robust methods and documenting protocols to eliminate ambiguity are two factors that analytical laboratories can control completely. Instrument-related inconsistencies, however, are often unavoidable and will require judicious adjustments and corrections.

By using technologies that have been thoughtfully optimised for easy method transfer, pharmaceutical companies can eliminate most of these variables, prevent time-consuming revalidations and improve efficiency.