Heat exchangers are used in many forms across a range of industries, but one of the more common applications is in food processing where they are used to heat or cool a bulk food product. The process requires precise management to ensure that the correct heat transfer takes place, producing a product at the required temperature while maximising efficiency. This requires expert knowledge in both steam applications and system design, both of which are areas where Bürkert Fluid Control Systems excels.

Ian Webster, Steam expert at Bürkert UK, reviews the key areas of focus when designing an efficient and effective steam heat exchange system. The initial design of a heat exchanger process is crucial in determining the efficiency, not only of the process itself, but also in terms of energy consumption and integration with the other production processes. Two of the most commonly used designs for continuous processes are 'plate heat exchangers' and 'shell and tube' devices, both of which use large surface areas to maximise the efficiency of the heat transfer process.

Having chosen the style of heat exchanger, the method of heating or cooling must be determined. In many cases saturated steam is used to heat food products as part of a cooking or sterilisation process, but using steam efficiently and safely requires expert knowledge to ensure this expensive resource is managed and controlled effectively. Bürkert has many years experience in designing steam control circuits and manufactures a wide range of control devices specifically for this application.

At the same time as providing the heat source, the steam circuits are often used to provide a Clean-in-Place (CIP) process at the food side of the circuit, which demands that there are no areas in which bacteria could accumulate. In terms of the steam pipework, it must be correctly sized and include properly installed strainers, steam traps and reducers so as to avoid problems with condensate.

Further consideration is also required for the control architecture, not only for the efficient and reliable management of the heat exchanger, but also in terms of connection to the other processes within the production facility. It is essential that the most appropriate style of control, both electrical and pneumatic, is implemented to ensure the most reliable and efficient control system.

Coupled to all of this groundwork are the actual control valves, sensors and actuators which need to work together seamlessly to deliver precise and reliable control of the heat exchange process. Bürkert has developed a wide range of control valves, pressure, temperature and flow sensors which can all be used to develop an efficient and accurate process control system. It has also produced a detailed Steam Site Guide, which can be downloaded from the company website, to help designers and maintenance engineers ensure that both new and existing facilities are properly managed.

Many applications require careful control of the steam supply to the heat exchanger, where a typical solution would be the Bürkert Type 2301 globe control valve, combined with a Type 8693 digital electro-pneumatic process controller. Following the Bürkert philosophy for modular components, the stainless steel valve is available in flange, threaded or welded formats, while the type of valve controller can be configured to suit each installation.

Legislation is in the pipeline relating to the design of valves and equipment used in heat exchangers, whereby they need to have equipment which is made from materials suitable for a hygienic processing environment and complies with local and European norms. This presents an opportunity for manufacturers of heat exchangers to not only improve the control and efficiency of their product but also ensure future compliance by installing a stainless steel valve and control head, such as the Type 2712 globe control valve with an Element controller.

In addition, detailed information about the process can be obtained from sensors such as the Type 8311 intelligent pressure transmitter, which can transmit real-time information as well as a 4-20mA control signal, if required. Additional information from flow transmitters, such as the Type 8032, or compact temperature sensors like the Type 8400, can also be integrated into a seamless control loop to provide accurate process control.

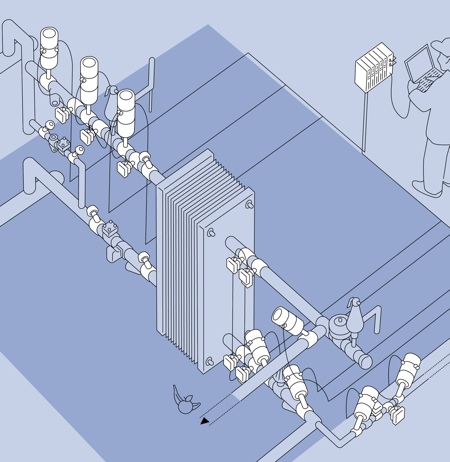

Bürkert also offers a complete design and build package for skid-mounted heat exchanger systems, which are produced to match the exact requirements of each customer. This service delivers a bespoke solution which includes all of the necessary monitoring and control systems for both the steam and the bulk product. Designed and built to the highest standards, this package can be delivered and integrated into an existing production facility by the highly skilled field engineers.

Valves for heat exchangers process diagram

Bürkert understands that the process of generating, conveying and controlling steam is one which requires expert advice and engineering knowledge, otherwise, at best, the process is inefficient, but at worst, serious injury can result. It aims to assist every customer in gaining a better understanding of their process and helping to make it more efficient and cost effective.

For free copies of Bürkert's Steam Site Guide and for information on Bürkert's free Steam Training Courses, please contact Helen Christopher, Bürkert UK Marketing Manager, T +44 1285 648 720; E-mail helen.christopher@burkert.com.