Pharmaceutical companies and equipment manufacturers are facing new challenges due to the boom in biopharmaceuticals. These individualised and costly medications require the development and production processes to be as flexible, safe and efficient as possible. Leading machine manufacturers have been working hard on new systems and are now presenting the first groundbreaking results. By integrating several previously separate processing steps, the latest filling and closing machines can be used for multiple types of pre-sterilised primary packaging.

The worldwide market for biopharmaceuticals is experiencing strong demand and is predicted to grow to more than US$167bn in 2015.1 Some 80% of these worldwide sales are generated by leading markets such as the US, Germany, Japan, France and Italy. However, the so-called pharmerging markets, such as China and India, are also expected to raise their share in biopharmaceuticals by more than 8% by 2015. Particularly in China, an increase in widespread diseases along with an ageing population is driving the development of new biopharmaceutical compounds. According to the World Health Organization (WHO), around 8% of cancer patients (one million people) lived in India in 2012, leading to the production of increasingly complex formulations.2

This trend towards ever more complex proteins is presenting pharmaceutical manufacturers with new challenges. On one hand, the biotechnology market segment is characterised by highly individualised products that are adapted to patients’ personal needs and the genetic markers of pathogens. On the other, such medication, which is mainly offered in liquid form and administered parenterally, is also expensive to manufacture. Unlike manufacturers of blockbuster medication, biopharmaceutical companies, laboratories and research facilities produce smaller batches in larger time intervals, but they depend strongly on flexible, safe and economical production operations.

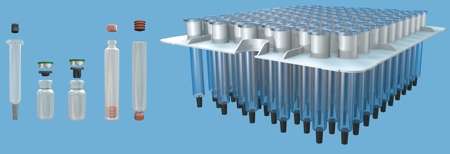

Use of pre-sterilised packaging has expanded from syringes to ready-to-fill vials and cartridges too

Here, manufacturers of pre-sterilised primary glass packaging make an important contribution. While pre-sterilised syringes have been on the market for many years, some of these manufacturers have now added other containers to their portfolio. With the support of leading equipment manufacturers such as Bosch Packaging Technology, they started the production and development of pre-sterilised, ready-to-fill vials and cartridges.

The pre-sterilised glass containers are generally delivered to the customer in a tub sealed with Tyvek, with each container individually inserted into a so-called plastic nest. The sealed tubs, in turn, are protected by a bag made of plastic and Tyvek. Since the preparatory steps for these pre-sterilised containers have already been carried out by the supplier, the purchase and operation of upstream machines for loading and washing, or for sterilisation and depyrogenation is no longer necessary.

Packaging and filling flexibility

However, even the most advanced primary packaging is profitable only when it is processed on equally advanced equipment. Filling small volumes of biopharmaceutical drugs into pre-sterilised glass containers requires platforms that process the containers with the utmost flexibility. At the same time, these platforms must satisfy the need for high product yields and low space requirements, as well as for maximum product and operator safety.

The more types of packaging that can be filled and closed with a single machine, the greater the space savings for the user. By integrating both filling and capping processes into one single machine, the need for a separate capping machine is removed. Thus pharmaceutical developers and manufacturers can conduct the entire processes in a small space.

Inside view of the FXS Combi with its integrated capping station

Another important requirement for the latest filling and closing machines is their compatibility with different filling systems. This not only allows pharmaceutical companies to adjust filling operations according to particular packaging and medication types; the ability to use filling technologies with single-use components also offers a cost-effective alternative to expensive cleaning operations for product contact parts.

The high development costs of biopharmaceutical drugs call for maximum efficiency of filling operations. Utilising quickly exchangeable format parts for the different packaging types is just as important as reducing product loss to a minimum. For instance, the latest filling technologies achieve almost 100% product yields, while a statistical in-process control ensures that glass containers leave the filling machine with exactly the required amount of liquid.

The individual ingredients of biopharmaceuticals are just as characteristic as the stringent safety conditions that are required for their development and processing. The focus is on protecting medications from microbial contamination and ensuring the machine operator’s safety. To avoid human interference with the substances, filling and closing machines should feature a high degree of automation and be compatible with different barrier systems, such as Restricted Access Barrier Systems (RABS) and isolators. The pre-sterilised containers can be fed into the filling module either manually or semi-automatically. If automatic tub and bag openers are incorporated upstream, the result is a complete and fully automated filling and closing line for pre-sterilised containers.

Meeting demand for packaging diversity

An example of a newly developed system for efficient processing of pre-sterilised packaging is the FXS Combi from Bosch Packaging Technology, introduced at Interpack 2014. This concept offers advantages, particularly for R&D, as well as for clinical studies. Instead of the usual three machines, a single unit will fill and close vials, syringes and cartridges. The packaging for a new drug often has not been defined at the early development stage. Hence, the combination of the three most common packaging types into one platform offers pharmaceutical companies a much higher flexibility in matching medications to the appropriate packaging type.

| FXS Combi with integrated capping station |

| Depending upon output and container, the FXS Combi with two or five positions processes pre-sterilised nested syringes, vials and cartridges. This new development from Bosch Packaging Technology is the first filling and closing machine of its kind with an integrated capping station for vials and cartridges. In the consistent monobloc solution, the capping of vials and cartridges takes place directly after the stopper insertion. This ensures the highest safety, as the container is immediately closed after filling. |

| The FXS Combi is an advancement on the proven FXS platform for syringes; a concept that has now been transferred to further pre-sterilised packaging types. Among others features, the machine offers flexible and quickly exchangeable format parts for diverse packaging types. The machine operates with a combi filling station with up to six dosing heads. This makes it suitable for all common filling technologies, such as peristaltic or rotary slide valve piston pumps as well as the single-use filling technology PreVAS. |

| A combination with different barrier systems, as well as integration into fully automated line concepts is also possible. Filling on a checkweigher during the start-up and run-empty process makes almost 100% of the pharmaceutical liquids usable for filling. Filling weights are checked via statistical in-process control. The filling and closing machine is also suited to processing vials for lyophilisation, which ensures a longer life span of the pharmaceuticals. |

Large-scale production machines are generally in operation almost every day. However, machines for small-batch production are used a lot less frequently. This results in greater efforts for the machine operators, because they need to adapt to each machine each time. Combination machines can provide a remedy, as they require less operator training. Furthermore, investments can be paid off faster, because the machine is operated more frequently. It also reduces infrastructure and running costs, while saving space at the same time.

New pre-sterilised containers offer biopharmaceutical manufacturers a greater choice of primary packaging options. This new diversity has also changed processing requirements. By combining proven machine platforms, different filling technologies and multiple packaging options, equipment manufacturers have paved the way for more flexible, efficient and safe processes. As a result, new filling and closing machines such as the FXS Combi are already establishing themselves as groundbreaking alternatives for biopharmaceutical filling operations.

References

1. IMARC Research Inc.: Global Biopharmaceutical Market Report (2012-2015).

2. Sandhu, Gupreet, Contract Pharma July/August 2014