While plate heat exchangers are still commonly used for simple viscous fluids such as water, milk and some thin oils, for most other applications tubular heat exchangers are the preferred choice. There are many different types of tubular heat exchanger available (such as annular space, double tube and multitube), but the biggest influence on efficiency is the type of tube used, rather than the configuration – corrugated tubes are more efficient at transferring heat than smooth ones and have a number of other benefits.

One advantage of corrugated tubes is that they prevent viscous fluids and suspensions from forming an insulating boundary layer on the tube surface

Increased efficiency

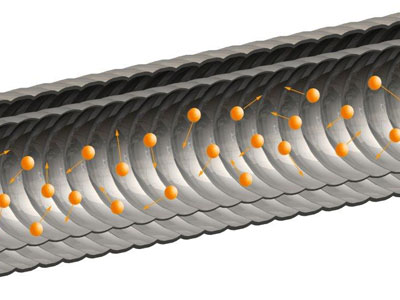

When a fluid passes through a tube, several things affect the way in which it moves, such as pressure, the nature of the fluid (how viscous it is), and the design of the tube wall. In a smooth tube, fluids generally follow a smooth path in which the particles which make up the fluid do not interfere with each other. This is known as laminar flow. However, where smooth flow is disrupted, tiny whirlpool regions form in the fluid and turbulence occurs. Unsurprisingly, this is known as turbulent flow.

Turbulence makes tubular heat exchangers more efficient by preventing viscous (thick) materials sticking to the wall of the tube, where they can act as insulation and prevent efficient heat transfer (known as a boundary layer). It also prevents materials in suspension from dropping out of the carrier fluid and having a similar effect. This is the main benefit of corrugated tubes.

Smaller footprint

Because a corrugated tube has an increase heat transfer rate compared to a smooth tube of the same length, the heat exchanger can be made smaller. For example, if corrugations increase the heat transfer by 10 per cent compared to a smooth tube, then the unit can be made 10 per cent shorter than an equivalent smooth-tube while delivering the same performance. The increased thermal efficiency – which can be up to three-times that of a smooth tube heat exchanger – also means that less space is required to achieve the same level of heat transfer. Depending on application, a corrugated tube heat exchanger can therefore be up to half the size of its smooth tube equivalent. This is why HRS’ heat exchangers are commonly specified for installations where space is restricted.

Corrugated tube heat exchangers have been used to replace spiral units at this water treatment works.

Longer running times

Not only does preventing the formation of a boundary layer in the tube increase the thermal efficiency of the heat exchanger, it also reduces the downtime needed to keep removing it. Therefore, the operational run times between cleaning cycles are generally much longer with corrugated tubes than smooth ones, further increasing the overall efficiency of the process.

Easier maintenance and cleaning

For some types of viscous material, a corrugated tube provides sufficient turbulence to prevent the need for mechanical agitation, such as in a scraped-surface or screw-driven heat exchanger. With no moving parts, a corrugated tube is much easier to clean and maintain, and may be more reliable, than a scraped-surface heat exchanger, although there are applications where a scraped surface heat exchanger is the better option.

When taken together, the benefits of corrugated tubes are significant. So much so that at HRS Heat Exchangers, we don’t used smooth tubes in our non-scraped tubular heat exchangers. The increased heat transfer efficiency, particularly at higher flow rates, means that less heat transfer area is required, so we can produce shorter, more compact designs which are also cheaper to manufacture.