The first areas that instinctively spring to mind when a process professional is challenged to reduce process control costs are usually purchase cost and installation. Why not? They are the obvious ones and they are the easiest to define and list.

When viewed as part of a system, however, purchase cost plays only a small part; managing the multiple signals from sensors and transducers differently can radically affect the total cost of ownership (TCO) for that process system.

Careful analysis conducted by Volker Erbe, Sensors Product Manager at process control specialist Bürkert Fluid Control Systems, investigating the whole life costs associated with field devices such as sensors, transducers and the control platform they are connected to, has revealed there could be far larger savings to be had from making changes to product selection at the initial stage of a project – changes that can have huge cost repercussions during the less obvious operational phase, such as training, start-up, process operator time, service, repairs and documentation.

Volker carried out the research to help define costs more accurately for Bürkert process field devices; he then identified where costs lie within a whole life process application and quantified the results of making better decisions early on in a project.

The initial question Volker started with was: What part do field devices play and what proportion of the cost associated with them can be saved?

'The quantity of field devices in process applications is increasing almost exponentially, based on a higher level of automation in today's processes. Our figures show that in a typical process application in food, pharma or general industry, about 20% of the overall investment costs are for sensor-based measurement devices and up to 75% of the TCO are costs in the operational phase, which we estimated at 15 years’ usage time.’

Overall process control costs and the possible cost reduction potential is, of course, dependent on variables within individual plant set-up, including the size in terms of I/O, building size, distances and the kind and complexity of processes and sub processes involved. Environmental conditions, such as high temperatures and high pressures, and the kind of medium, e.g. aggressive, dangerous or difficult fluids or gases of any kind, together with other special conditions such as process security demands, standardisation and norms, plus certificates all play a part. In addition key local priorities, conditions and resources, such as education and the level of redundancy required, often have to be considered.

In each of the different areas of cost there is a potential for cost reduction

‘In each of the different areas of cost, however, there is a potential for cost reduction. We concentrated on the effects in relation to a control loop, linking sensors and transducers (flow, temperature, level, pH etc.) in a measurement and control (e.g. PID) loop with positioners and valves. We ran several simulations and also drew data from a range of real applications in order to reach trustworthy medians in terms of cost.’

Initial costs

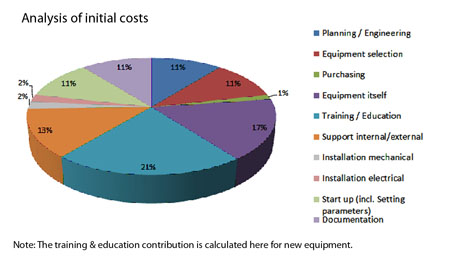

Planning is a cost that almost always justifies the investment, as does any time taken to specify instruments and equipment. Purchasing has an administrative cost associated with it and Bürkert found that, remarkably, the equipment itself accounted for only around 17% of the initial cost - less than the cost of training when dealing with new equipment.

Other items taken into consideration included support from both internal and external sources, installation – both mechanical and electrical, including wiring of all external hardware for comms and power – plus commissioning and start-up costs, including all necessary documentation for plant, instruments and wiring.

Analysis of initial costs

It is not until you reach this level of analysis that you start to see a pattern forming in the peripheral activities, and then start to appreciate the hidden costs. Only then do you begin looking to specify a solution that reduces indirect costs, knowing that the saving can be significant when compared with the initial purchase cost of the devices themselves.

The saving can be significant when compared with the initial purchase cost of the devices themselves

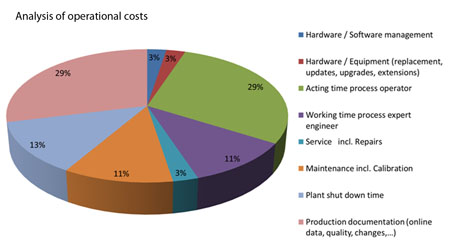

Operational costs

The company defined operational costs as recurring activities, including: on-going hardware and software management (replacement, updates, upgrades, extensions); production monitoring and control; maintenance, service and repair; any enhancement carried out during the life of the product; additional documentation (online production data, quality, changes); and then finally decommissioning, including recycling costs (one time costs only).

Analysis of operational costs

’To be totally accurate you have to analyse your own plant to have a base line which gives you information about the share of operating costs using your plant figures, identifying which area is of interest for achieving the best results in cost reductions. You can, however, use our broad analysis to draw some obvious conclusions.’

Plant figures can identify which area is of interest for achieving the best results in cost reductions

To show savings in operational terms, the flexibility of a product is vital, as is its modularity in terms of hardware and software. Sensors and transducers have a fixed operational envelope, and a minimal price differential between manufacturers of reliable quality products; the controllers they are connected to, however, can affect costs dramatically.

Each product should ideally have a wide range of usage. This leads to device consolidation and a reduced number of different products in use, which can then generate a virtuous circle that requires reduced training effort, allows more flexible staffing and reduced effort in all production processes as well as managing the products in use.

So how does a field instrument support cost reductions in practice? The simple answer is to specify the right one in the first place.

The handling of a product must be easy and repeatable; this typically means no specialist tools required for installation or commissioning

The handling of a product must be easy and repeatable; this typically means no specialist tools required for installation or commissioning, hence no hidden costs and no need to carry large amounts of kit in order to have a wide range of tools to hand.

Data management should be easy; Bürkert realised that simple things such as the upload and download of settings, cross-referenced with data storage capacity, and easy configurability of multiple items made a huge difference to the end user. A more intelligent field device needn't mean a more complex one to handle, because that would probably negate any cost saving in process.

All this research was taken into account in the design of the multiCELL 8619 compact field-based process controller; this meant investing in multiple interchangeable control boards for pH, conductivity, inputs and outputs, plenty of on-board intelligence with intuitive menus and parameter settings, plus set programs for controlling a variety of analogue and digital process signals via a simple menu structure that included text and icons, all displayed on a large, clear, backlit screen that could be easily interacted with in a process environment.

The result of all this application knowledge in one product means it is hugely less expensive than a system including a separate controller, separate I/O, comms gateways and an HMI, let alone the attendant commissioning, wiring housing and installation cost.

‘The real advantage of one universal controller, specifically designed to connect sensors and transducers in process control environments is the impact it can have on reducing operational costs.’

The real advantage of one universal controller is the impact it can have on reducing operational costs

With a multiCELL, for example, you can configure once, then copy and paste to other devices via an SD card, or just adapt the settings and save time. User configurable display views mean that the device can be configured once for different users or different processes, and then used to switch between different stored views.

Maintenance, monitoring interrogation and data upload and download are all possible via one operator interface. Furthermore, selective access via password can provide data security and minimise handling errors by selective allocation of activities to different user responsibilities. On-screen instructions also mean quick learning and no need for a bulky manual or laptop to be at hand.

Integrated menus support calibration routines for sensor, analogue inputs and outputs, allowing configuration without having to use separate tools and wiring. The device also has a signal simulation function for sensors, input and output signals and so supports easy start-up procedures, winning time on verifying the causes of errors.

Not only is the device easy and intuitive to use, thereby reducing the training and manpower required operationally, but because it performs so many functions, standardisation is easy and the cost of on-going support and maintenance is minimised.

The device will tell you which version of its software or firmware it is running and allow easy updates and upgrades without losing custom parameter sets. If a device ever needs to be exchanged it can simply be replaced and the SD card used to transfer the operating parameters, providing a totally plug-and-play replacement for a very advanced process control function.

‘The strongest argument for the future of usability is that by using scrolling functions and icons with a very user friendly keypad, we have effectively created a multi transmitter for various types of sensors in combination with a full process controller that you can install, use and interact with as you would use a mobile phone.’

So where do you apply a product like this?

A typical customer for this type of new intelligent intuitive field multi-transmitter/controller has a process application with multiple sensor types and arrangements in use, plus actuators and valves for performing functions in recurring applications; all providing a variety of different signals at different rates and in different formats requiring a lot of different know-how just for daily operation.

A typical customer has a process application with multiple sensor types and arrangements in use, plus actuators and valves for performing functions in recurring applications

The solution would be to use a multiCELL multi-channel/function/transmitter/controller as a central device, connect all the different sensors, perform all the necessary functional configuration in only one device, and for each application store the configuration on an SD card for reuse.

Conclusion

Bürkert firmly believes that there are substantial process control cost savings to be made from the complete lifecycle of a process multi-transmitter/controller, that cost reduction starts with device selection and savings are made both directly and indirectly. Each individual plant needs to carry out some analysis based on its own individual instrument usage, the kind of processes taking place and the individual operating conditions.

Thinking about usability throughout the product life cycle and the real TCO has led Bürkert to create a very different type of product and one that the company believes indicates the future for intelligent process field devices.

Volker has worked with process automation for more than 25 years and as Product Manager is now involved in both new product and systems development; he also delivers training courses on a variety of measurement field devices and controllers.