As it directly relates to costs, energy efficiency is increasingly important for us all. More stringent regulatory pressure is also on the horizon in the form of the EU Commission’s proposed revision to the EU Energy Efficiency Directive (EED).

The revised EED will make the EU’s energy saving objective legally binding, obliging EU countries to collectively reduce their energy consumption by 9% below 2020 levels by 2030. Additionally, by 2024, EU countries will most likely have to achieve new annual energy consumption savings of 1.5% (up from the current level of 0.8%).

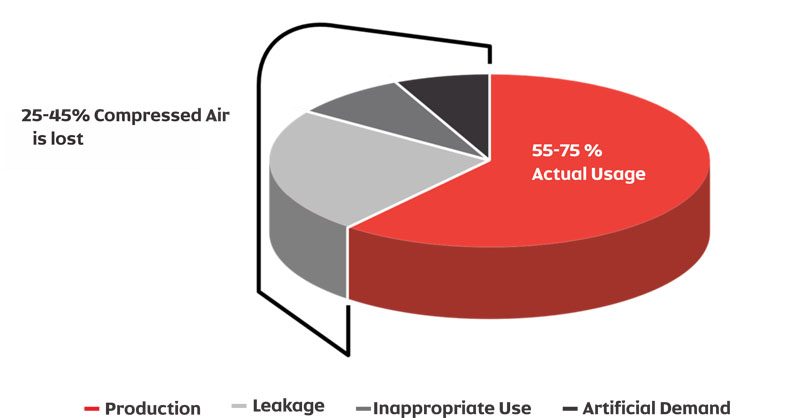

In manufacturing processes using compressed air, energy efficiency improvements are critical; air compressors consume approximately 12% of a plant’s electrical energy. What’s more, during the lifespan of an air compressor, 80% of the cost is energy use and 20% is the cost of the unit. But, do compressed air users have the big picture of where these costs come from and what contributes to them?

Looking beyond the system

There are many technical and economical choices to make when taking the right approach to reducing the energy intensity of compressed air systems. Not so long ago, industry rightly looked beyond the unit efficiency to the system and system efficiency.

Greater awareness of operational needs and the increased pressure to reduce energy use and improve efficiencies prompted a closer examination of the system. More granularly, how do we balance operational needs, capital costs, the lifespan of critical assets and energy use?

The traditional total cost of ownership (TCO) approach looks at the energy cost based on a compressor package’s power or specific power consumption. Whereas a complete operational analysis looks at everything from the compressor to the environment in which it operates, as well as operational demands such as peaks and troughs in air demand and operational expansion planning.

A finite analysis of the bigger picture reviews how even the most minor system elements impact the energy consumption associated with the compressor.

The aim is to strike the right balance between technical and economic choices; that is, compressor units, capacities, operational parameters, energy efficiency, planning for future air demand changes and considering energy costs related to leakages, inappropriate use of air, artificial demand, etc.

Compressed air users need to look at their operational demand and see what compressed air is necessary for their specific operation throughout the production cycle. Then, they should study how to optimise the compressor room and question the hardware and the settings of the compressed air installation. After this study, compressed air users can truly safeguard their assets, investments and energy costs … and ultimately achieve a new low in compressed air TCO.

Close, but let’s take a wider look at safeguarding your assets

To describe it better, let’s take a hypothetical look at what happens when a customer expands its manufacturing site (adding another production line, increasing its manufacturing capacity, etc.). In such a case, a typical discussion between the compressed air user and the supplier about the new compressed air demands starts with the customer’s request for more air — assuming that an additional or larger compressor is the solution.

The thing is, simply adding another compressor is not the answer when the surrounding system stays the same. This can result in too much stress being placed on the system’s existing structure and can lead to reduced overall efficiency.

Why? When a manufacturing plant or line is being built, a compressed air system is planned and designed to fit the capacity load of a particular production process. It all works as planned and achieves expected results. When the company’s operations grow and the plant increases production, the air demands change.

And adding another compressor to fit the increasing needs is not the answer. Before even considering that, compressed air users should work with the experts to conduct a detailed analysis of how the current system is performing at a given time and within given demands.

Before any decision is made, a holistic analysis of the entire production system, historical and planned air requirements, current piping and checks for leaks should be done.

Quite often, the expansion of a manufacturing site or production line won’t even require adding another compressor. Finetuning the existing assets to run at proper and adapted loads — not at the highest pressures or extreme limits — can result in lowered pressure on the entire system and reduce energy consumption.

It’s an easy route to add another compressor, but taking a holistic approach — analysing and optimising the existing system and its elements — is the key to safeguarding your assets and achieving the desired energy efficiency improvements.

Let’s audit, right-size, and implement

Before deciding whether to replace a compressor, add another one or adjust the existing system, an audit of the operations is necessary. A compressed air auditor can check the entire system and establish the input, state of the compressor units, how they’re running, and what exact pressures are required.

This will paint a picture of the system with its surroundings, elements, pipework and critical consumption. With this knowledge, we can move to the next step, which is making an educated decision about how to optimise it to meet the new requirements. Very often, the expanded production requirements can be met with the same power and adjusting the airflow (of course, depending on the size of the expansion). It’s all about right-sizing the air needs.

Let’s show this based on a concrete example. A plant with a current compressed air demand is expanding its operations and requires an increase of up to 35% in compressed air. Our job is to see how this additional compressed air demand can be achieved and whether adding a new compressor is necessary.

The audit shows the system’s current state, including piping, running pressures throughout the day and any cyclical changes in demand. The next step is to see how the existing system can be optimised to generate the additional demand with the same power. This can be done by analysing and right-sizing the system and taking a closer look at the following.

Impact of leakage: Leakage happens throughout the system with time. It can be caused by ageing hoses, improper joints, installations, wrong parts or corrosion. We estimate that 20–30% of compressed airflow can be lost because of leakage. Leakage via a 3 mm hole can consume 4 kW/h of electricity, incurring an annual loss of 19,200 kW (at 7 barg, 16 h/day for 300 days in a year).

This creates enormous room for improvement. Leaks occurring in pipe joints and connections can be prevented by simple, appropriate tightening, proper seals and/or sealing media. Suitable quality fittings, tubing and connections last longer. An audit can establish risk areas while having a leak detection and maintenance programme at regular intervals will reduce future incidences.

Inappropriate use of compressed air: This can mean many simple and ordinary things, such as blowing off washed parts or even operators who work in a dusty environment and use the compressed air supply to blow the dust off their clothing. These things happen. Checking and eliminating the inappropriate use of compressed air throughout the plant can contribute significant gains.

Artificial demand: This is the excess volume of air required by unregulated end uses as a result of supplying a higher pressure than necessary for applications. This equals an unnecessary consumption of energy. A simple strategy of performing the proper selection, installation and use of pressure controllers on top of preventing leaks and inappropriate use can be of great help here.

Optimising the pressure band: Setting the correct pressures can be done by establishing and understanding requirements, determining pressure losses in the piping system between the compressor and the production equipment, and setting the proper load and unload pressure as low as possible to meet application demands.

Reducing the compressor set pressure by 1 bar (14.7 psi) can result in a 7% reduction in terms of total compressor power consumption. At 16h/day for 300 days of operation, that represents 36,960 kWh of power consumption savings for a 110 KW compressor.

Minimising pressure loss: Although no system is immune to pressure loss in the piping system and downstream equipment, the pressure difference between the point of discharge from the compressor and point of consumption can be minimised and kept as low as possible.

It starts with the piping design and by placing the production and application points close to each other and optimising the size and shape of the piping. Downstream equipment should be selected at the lowest pressure drop and maintained following the air compressor supplier recommendations (and cleaned periodically).

A properly executed audit with the right partner will show a complete consumption pattern of your compressed air with time, helping with leakage detection, compressor sizing and energy optimisation. This data can then be used to make the right decision about ongoing operations and future system expansions.

Whether compressed air users, compressor suppliers, service teams or operators, we can all improve our energy efficiency, operational effectiveness and costs by looking beyond system efficiency to optimise compressed air demand and supply. The added benefit of this approach pays off by safeguarding your assets, reducing the risk of downtime and maintaining efficient production.