Advaxia Biologics, a leader in GMP compliant contract manufacturing and part of the IRBM group, has overcome challenges it faced in its filling/capping suite using a Flexicon FPC60 system with environmental barrier technology from Franz Ziel GmbH.

The Flexicon FPC60 fill/finish system was a necessary improvement to ensure Advaxia Biologics an even higher level of quality and an enhancement of the services offered on the market.

The previous vial filling configuration at this site was focused on small batches and included the Flexicon PF6 peristaltic filler and Flexfeed 20 semiautomatic vial feeding system. The caps were placed manually before being crimped by the Flexseal 10 capping machine and installed on the benchtop under a Laminar Air Flow control system.

It was recognised that investment in new automatic filling/capping operations would provide multiple benefits to their process, including batch reporting and zero waste.

To maintain the highest level of quality, the challenge for Advaxia Biologics has always been to train, check and maintain the skill levels of operators as they are responsible for much of the entire filling process, including the critical step of final filtration of the pharmaceutical drug product.

Reducing the number of operators involved in this critical process, as well as operator input through recipe drive auto-adjustments, would help to address this challenge.

A Franz Ziel and Flexicon collaboration

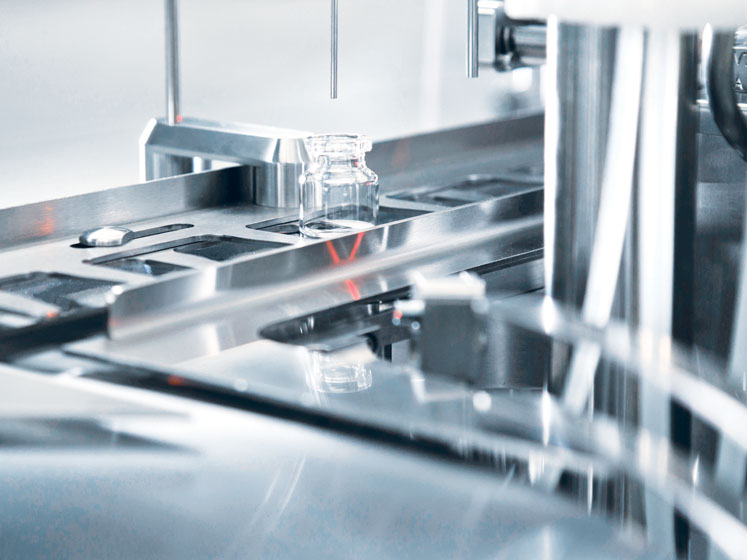

Working in collaboration, Flexicon and Franz Ziel developed a solution for Advaxia Biologics. An FPC60 filling/capping system was integrated with environmental barrier technology to ensure both the product and the operators were fully protected and the platform met all regulatory requirements.

Advaxia Biologics works with two sizes of Stevanato Group EZ-Fill vials (2R and 6R) and presterilised ready-to-use (RTU) vial trays for automatic loading — with caps and stoppers of 13- and 20-mm diameter.

The fill volumes fall within a variable range between less than 1 mL and 5 mL. With the previous filling system, the batch sizes ranged up to 1000 vials; with the new FPC60 machine and the new suite, Advaxia Biologics is able to offer approximately 5000 vials.

To maintain aseptic conditions during the filling and capping of products that are particularly susceptible to external contamination, or considered to be biohazardous to operators, a closed Restricted Access Barrier System (cRABS) or isolator provides the highest level of protection.

The FPC60 automatic filling and capping machine is equipped with fully electric systems and does not require compressed air, saving Advaxia Biologics both time and money in terms of installing a new compressed air line that’s compliant with the Class A environment.

The No Touch Transfer (NTT) compliant debagging system ensures that vial trays are unwrapped of their protective packaging and introduced into the critical filling area without human contact — all while maintaining the required levels of safety and sterility at good production speeds.

The FPC60’s remote Human-Machine Interface (HMI) enables recipe and user creation from outside the cleanroom, providing ease of use and time savings. Once in the cleanroom, recipes simply need to be recalled and the machine fully adjusts itself based on the recipe parameters, increasing repeatability and reducing risk.

Improvements in the Advaxia Biologics filling/capping procedures

The new system reduces contamination sources from critical processes, whilst also providing greater repeatability, improved quality assurance and high levels of traceability. A further advantage is the reduced number of operators required to fill a batch compared with the previous process.

Traceability of the entire filling process takes place through software that controls all automated systems and keeps track of batch records and audit trails.

Reduced rejection rates and zero-waste start-up means that vials filled during priming and calibration are viable.

Branislav Mitrovic, Flexicon’s Sales Manager, said significant challenges had to be overcome in the Factory Acceptance Testing (FAT) process for Advaxia’s FPC60 at the end of 2020, owing to the Covid-19 pandemic. He said: “As it was not possible to travel around the world at the time the FPC60 was set up, it was necessary to perform the final FAT for the system remotely using Advaxia’s vials, caps and tear-off caps."

"We do the same tests according to the FAT protocol documentation regardless of whether it’s done with the customer present or remotely. The remote FAT typically takes 4–5 days (8 hours per day) and requires concentration, teamwork and commitment.”

“Advaxia Biologics had previously used a Flexicon system, so the move to a much higher volume automated filling/capping system is a perfect example of known and reliable scale-up technology. It was a moment of great satisfaction when the test was successfully completed and the Advaxia Biologics FPC60 was ready to be shipped."