Today’s innovative therapies have not only made manufacturing more complex, they have also put more pressure on supply chains and increased the regulatory burden associated with maintaining compliance amid diverse regulatory expectations. In the words of US FDA Director, Janet Woodcock, 21st century pharma should be a “maximally agile, flexible manufacturing sector that reliably produces high quality medicines without extensive regulatory oversight.”

We have seen significant progress in the application of science and risk-based approaches outlined in prior ICH guidelines (Q8, Q9, Q10 and Q11); however, a lack of harmonised requirements for lifecycle management are a disincentive to manufacturers to make improvements that increase process robustness on Established Conditions (ECs).

One post-approval change can take up to 5 years to implement across all regions, resulting in significant costs and potential supply disruption to the patient.

ICH Q12 focuses on post-approval changes to chemistry, manufacturing and controls (CMC) in a more predictable and efficient manner; one that’s supported by a company’s pharmaceutical quality system (PQS) and follows regional GMP requirements.1

One of the guideline’s underlying aims is to globally harmonise CMC change management … and industry has high expectations that it will significantly reduce regulatory burden, related costs and approval timelines.

However, it is up to each regulatory region to choose how to implement Q12. In Europe, however, this has come with disappointment. Owing to the current EU legal framework, the guideline cannot be implemented, reducing the impact that it can have on ECs. Other tools and concepts in the Q12 guideline that are not in the EU legal framework will be considered when this framework is reviewed.2

Outlined below is a detailed look at the primary points of ICH Q12. From initial concept, the aim of ICH Q12 was to “promote innovation and continual improvement, and strengthen quality assurance and reliable supply of product, including proactive planning of supply chain adjustments.” ICH Q12 intends to achieve this through the use of increased product and process knowledge to benefit patients, industry and regulatory authorities.

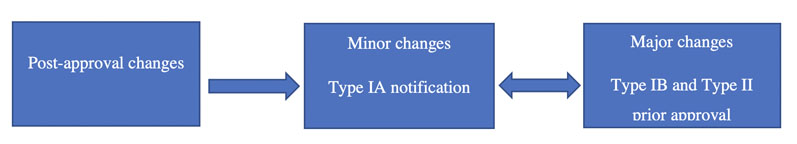

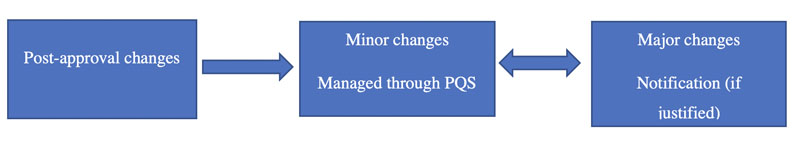

The drivers to improve the product life cycle include innovation, patient access, compliance, process robustness and improved supply chain management. The traditional model for post-approval changes involves prior approval by regulatory authorities or post-change notification.

Using the ICH Q12 toolbox, the approach could be seen as follows:

Implementing this new approach under ICH Q12 will require using the tools and enablers throughout the product lifecycle. Below, the guiding principle of each tool is discussed.

PACMP

At present, the most globally useful tool is the Post-Approval Change Management Protocol (PACMP). The PACMP has been in place for several years in the EU/US and the introduction of ICH Q12 is expected to increase its frequency of use.

The PACMP or Comparability Protocol (US terminology) is a comprehensive plan to assess the effect of a proposed change or multiple (related and consequential) CMC-only post-approval changes on the quality of a product (identity, strength, purity, potency, performance and stability). These protocols provide predictability regarding the information required to support a change and the type of regulatory submission based on prior agreement.

PACMP is a two-step process: first, a review of change and alignment of requirements by the regulatory authority prior to execution is done, followed by a shorter review of protocol execution by the regulatory Authority. The benefits of a PACMP include a clear agreement between the agency and the marketing authorisation holder (MAH) regarding the information required to support the change and potential to reduce the timeline for approval.

A PACMP can also support continuous process improvements, access to expanding markets with the accelerated addition of manufacturing sites and improved supply chain efficiency.

Established conditions

Established Conditions (ECs) comprise legally binding information (registered details) that’s considered to be necessary to ensure the process performance and desired quality of a medicinal product. ECs for a drug product include the manufacturer, batch formula, storage conditions and specifications.

Changes to ECs need to be reported to the relevant regulatory authority. In contrast, information provided in narrative form is considered to be “supporting information” and is required to accompany ECs. It is intended to provide background and auxiliary information regarding the development and manufacture of a product.

It also helps to justify the initial selection of ECs and their reporting category. Changes to supporting information will not require regulatory action but will be managed by the PQS. Process validation would be considered to be supporting information.

The MAH must clearly identify the conditions considered to be ECs and supporting information in the various CMC sections of the CTD module. The rationale for the ECs must also be provided. Post-approval changes to ECs require different reporting categories dependent on the level of risk associated with them.

Changes to High-Risk ECs must be reported for prior approval. In the current EU guidelines, there is no framework to recognise ECs or product lifecycle management. By contrast, the US FDA fully recognises ECs.

Product lifecycle management (PLM)

The PLM document intends to facilitate regulatory assessment and inspection by acting as the central repository for key elements of the product lifecycle strategy, such as ECs, PACMP and post-approval CMC commitments. Simply put, it is a summary that conveys to the regulatory authority how the MAH plans to manage post-approval CMC changes.

The document should be maintained throughout the product lifecycle as needed. A detailed example is provided as an annex to ICH Q12. This example is a clear and well-structured tool to create a PLM document. It is intended that the PLM is submitted with a new product application or alongside variation-defining ECs.

Summary

As global implementation of the tools presented in ICH Q12 is still some way off; it remains to be seen if there will be a reduction in administrative and regulatory burden for the MAH. An effective PQS as described in ICH Q10 and in compliance with regional GMPs are necessary and will be vital for the success of the ICH Q12 toolbox.

References

- Final Concept Paper Q12: Technical and Regulatory Considerations for Pharmaceutical Product Lifecycle Management dated 28 July 2014 Endorsed by the ICH Steering Committee on 9 September 2014.

- www.ema.europa.eu/en/documents/other/note-eu-implementation-ich-q12-guideline-technical-regulatory-considerations-pharmaceutical-product_en.pdf.