A step in the biomanufacturing process that enables such convenience is ultrafiltration with single-pass tangential flow filtration (single-pass TFF). Single-pass TFF is an enhanced approach to the existing TFF technology that has been used for the purification of monoclonal antibodies, therapeutic proteins and vaccines at different steps within downstream processing.

In this mode of TFF, the feed solution is pumped through a series of filters to produce permeate and concentrated retentate. The once-through flow path of single-pass TFF offers the advantages of reduced footprint, shear exposure and both working and hold-up volumes, which in turn lead to higher plant productivity.

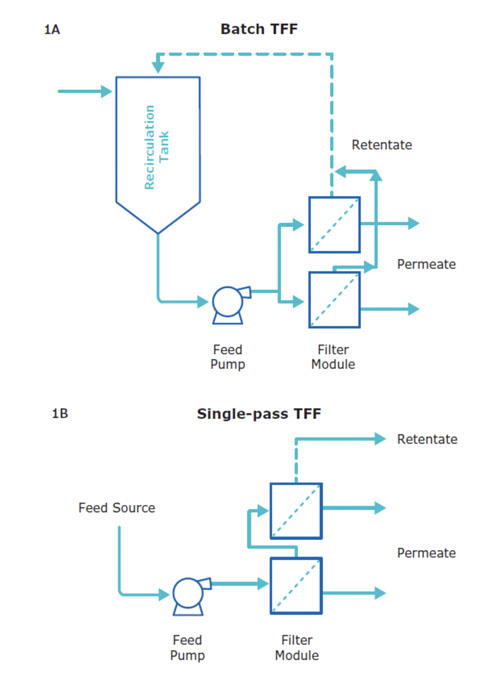

Figure 1: Compared with the traditional parallel configuration of batch TFF (A), single-pass TFF (B) produces concentrated retentate after one pass through filters in series, eliminating the space-limiting recirculation loop

What is single-pass TFF?

Traditional TFF operates in batch mode by recirculating the feed/retentate through filters assembled in parallel until the desired conversion is achieved (Figure 1A: termed hereafter batch TFF1). Single-pass TFF is a different approach to this filtration process.

This method utilises a longer feed channel path to reach the desired conversion after one pump pass (Figure 1B). The absence of a recirculation loop allows the retentate to flow downstream and, as a result, reduce hold-up volumes, eliminate pool tank requirements and enable continuous processing.

In single-pass TFF, product conversion is improved because of increased feed residence times on the membrane. Cassettes configured in series have a longer feed channel flow path than that of cassettes in parallel with the same total membrane area. This provides the feed with a longer residence time for more efficient permeation, enabling high concentration factors (>10X) to be achieved after a single pump pass.

The feed residence time is also controlled with a steady, low feed flow rate (approximately one tenth that of batch TFF). For example, a feed volume of 0.3 L/m2 running at a feed flow rate of 0.5 L/min/m2 would yield a residence time of approximately 35 seconds. At lower feed flow rates (<0.5 L/min/m2), the residence time would be greater and correspondingly result in higher retentate concentration after one pass.

Versatility in bioprocessing

During the production of biologics, single-pass TFF enables inline volume reduction to decrease tank requirements, reduce the size of subsequent steps, concentrate with inline buffer addition for desalting and facilitate high final concentrations with high product recovery.

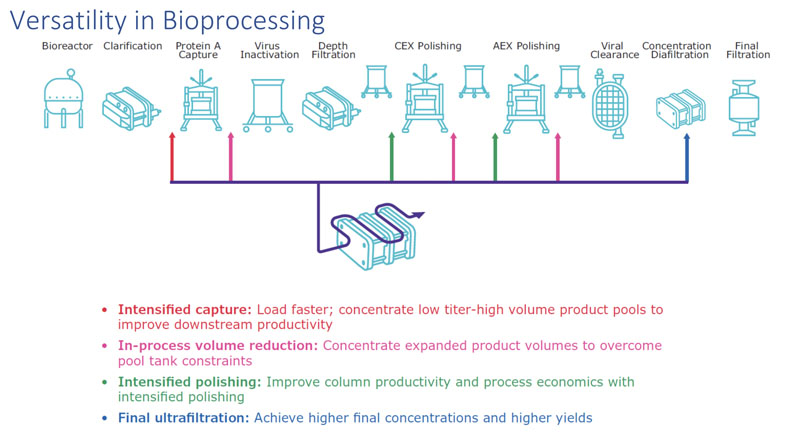

The small footprint of single-pass TFF facilitates the inclusion of an inline concentration step anywhere within a biomanufacturing process where volume reduction is needed, including before or after a column chromatography step or at final concentration and formulation (Figure 2).

Figure 2: Single-pass TFF can be integrated anywhere within a biomanufacturing process to address volume changes

Before chromatography

Inline concentration before column chromatography enables faster loading and increased column capacity for improved plant run rate and productivity. Preprotein A single-pass TFF is an ideal way to process large volumes of molecules that have low titres to reduce column loading times and debottleneck the manufacturing process when the post-harvest tank size is limiting.

Moreover, single-pass TFF before ion exchange chromatography enhances the efficiency of the polishing step. Intensified polishing offers means that less dilution is required to adjust pH and conductivity, which ultimately increases column productivity and reduces the use of consumables, contributing to improved process economics.

After chromatography

The concentration of in-process product pools eliminates the volume constraints that emerge from substantial volume expansion after a column chromatography step or sequence of steps. The significant dilutions required to desalt product pools can result in volumes that exceed tank capacities, requiring a certain amount of product to be discarded to achieve proper conditioning. In such cases, single-pass TFF is an ideal way to reduce overall volumes, debottleneck a process and maximise product mass recovery.

Although upgrading equipment may present a direct solution, single-pass TFF is an immediate option that, by comparison, requires little capital investment and space. More so, single-pass TFF improves facility fit by eliminating intermediate pool tank requirements and reducing the size of subsequent steps.

Final concentration

For high-value final products, single-pass TFF is used to maximise product recovery by processing low working volumes. The smaller footprint of single-pass TFF offers lower hold-up volumes per square metre of membrane compared with batch TFF.

This reduces recovery flush volumes and minimum working volume constraints. Furthermore, higher concentration formulations are achieved during final ultrafiltration with single-pass TFF as it minimises recovery dilutions, a capability that is ideal for highly viscous injection formulations.

Case study: intensified polishing

The strategic adoption of single-pass TFF in a biomanufacturing process can be showcased during an intensified polishing step. Intensified polishing with Pellicon cassettes and Eshmuno Q anion exchange (AEX) resin is a linked process wherein feed material is continuously concentrated before it is loaded onto the column. The intrinsic benefit of precolumn concentration is volume reduction, which extends to

- faster loading times

- easy manipulation of pH or conductivity

- greater column capacity

- reduced post-column pool tank volume

- savings in materials and operational costs.

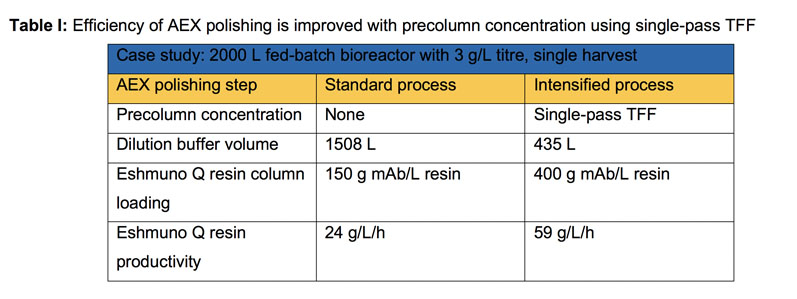

To assemble an intensified polishing step, the column is simply connected to the single-pass TFF retentate port. Inline dilution is accommodated before or after the concentration step. In a case study, single-pass TFF with Pellicon cassettes significantly reduced dilution volume requirements to adjust conductivity before running the column, enabling higher column mass loading and productivity compared with standard polishing (Table I).

With improved mass loading, resin and process volume requirements are reduced in an intensified polishing step. From a facility design perspective, reduced buffer and product volumes can considerably decrease tank size and footprint requirements for optimum facility fit.

Single-pass TFF also improves process economics despite the additional cost of membrane, which is more than offset by savings associated with buffer, resin and sterile filtration. Thus, the overall benefits of single-pass TFF concentration extend beyond volume reduction for a more productive and cost-effective manufacturing process.

Summary

Use of single-pass TFF with Pellicon cassettes is an effective and streamlined strategy to tackle volume challenges within downstream processing. As a continuous operation, single-pass TFF concentration can be linked with other unit operations to eliminate tank bottlenecks, increase the efficiency of polishing steps or optimise facility fit. Pellicon cassettes offer unique user-configurable single-pass TFF capabilities, including easy module configuration, precise linear scaling and cleaning flexibility.

Single-pass TFF with Pellicon cassettes is applicable to a wide range of molecules and conversion targets, and users can quickly and easily determine module design and scalability requirements according to their specific process needs.

With simplified hardware and low footprint, single-pass TFF is easily accommodated anywhere within a biomanufacturing process. The operational flexibility provided with Pellicon cassettes offers facilities the accessibility to integrate single-pass TFF without major capital investments to quickly mitigate in-process volume challenges and meet market demands.