At the heart of the QbD movement is a data based understanding of the design space of your process — rather than just the empirical support of release testing — to know that the product being made is of consistently high quality. However, because of the association of QbD with expansive data generation and process validation, there is a perceived negative implication to development cost and timing. Therefore, many organisations opt to defer the use of DoE in early development. In particular, small-to-mid-size pharmaceutical and biotech companies with aggressive timetables are hesitant to invest heavily in early stage process development; the risk of the cash burn rate exceeding funding during progress through to the clinic is high. It becomes a balance of risks: invest in a molecule that may fail in the clinic or defer development and face potential delays in clinical trials and commercialisation because of process-driven supply issues.

Yet, the mitigations of these risks do not need to be mutually exclusive when using DoE in early phase development. What’s key is a focused approach, leveraging both experience and ensuring that automated technology is fit for purpose in terms of its design and execution. It can be easy to fall into the trap of applying a DoE study to every set of process parameters. But few of these may be truly impactful in reducing risk.

During the development cycle, it is assumed that many unit operations may alter as the process evolves; therefore, it can feel as though investment in their parametric controls is wasted time and effort. However, it’s all about a focused quantitation of risk. A common yet effective tool for this is a Design Failure Modes and Effects Analysis (DMFEA). Still, a risk assessment is only as good as the combined experience of those involved.

In early development, few if any runs have been performed. It becomes less dependent on observed process failures and their rates of occurrence than on an assessment of what could go wrong and how likely is it that it will. In that exercise, there is no replacement for experience. How many of us have been burned by not knowing how simple factors such as time, temperature and solvent volume can interact to impact a purging profile or desaturation rates during crystallisation? Whether that’s been observed or not for the process being evaluated, it’s known from past experience that this has a high potential rate of occurrence and a high probable impact. The use of a risk assessment geared around control of the quality attributes of the product — leveraging an experienced cross-functional team — ensures a targeted approach and prioritisation for any DoE.

A true QbD approach will explore wide parametric ranges to fully understand a process design space and identify edges of failure. This enables the identification of critical process parameters based on the margin between proven acceptable and controllable ranges. This can mean extensive range finding and, potentially, multiple scalings of the DoE. This approach is most critical when commercialising according to current regulatory expectations and ensuring that filed ranges are justified and appropriately inclusive. However, in the early clinical stages of a process, it is not critical to know the entirety of the design space.

It is, however, most critical to know how the process will perform within the controllable ranges of the equipment. This allows a more focused effort on a smaller range, eliminating any scaling issues and reducing the number of range finding studies required to establish edges of failure. This focused study with a limited parametric range makes for an efficiently designed scope of work for any DoE.

Getting from A to B

Once a targeted, risk-based design has been established, it’s all about the execution. Larger, full factorial studies with centrepoints can appear to involve a dauntingly large number of experiments: three factors, one replicate and triplicate centrepoints can mean 19 experiments. This makes a traditional, limited one-factor-at-a-time (OFAT) model feel more efficient. OFAT experimentation drives in a straight line between points A and B. Therefore, getting to point B again may be dependent on driving that same line every time.

Exploring the design space, even in a more focused fashion, through DoE, will determine if you are walking a tightrope or cruising a four lane highway. Overcoming the perception of value of each experiment versus the combined value of an experimental matrix is key. The sum of understanding derived from DoE is greater than its experiment parts. By leveraging automated platforms, execution of these valuable design matrices becomes more cost-effective and time efficient.

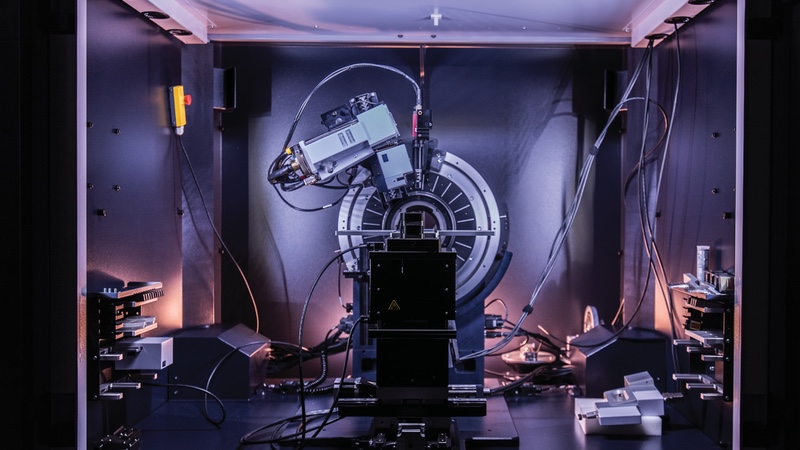

In nearly the same amount of time as an OFAT experiment, a high-resolution full factorial study can be performed using automated parallel reactor systems. Automated dosing, reaction, isolation and analysis with systems capable of up to 288 parallel experiments makes for an efficient execution phase of the DoE work. This further opens an economical door for the incorporation of lower resolution range finding design models and interwoven Principle Component Analysis for discrete factors such as catalyst, solvent or reagent selection. This can then also drive optimal outputs, not just process robustness.

In early clinical development, OFAT and other simpler, more empirical experimental approaches are critical tools. However, it will not adequately assess more complex multifactor unit operations such as synthetic reactions and crystallisations. It becomes difficult to determine higher order interactions and can result in death by a 1000 experimental cuts to understand a process. Or worse, a failed production run can occur from missing a critical process control during development — both unfortunately quickly extend timelines and cost.

Therefore, leveraging a smarter approach to the application of DoE using strong technical experience in a risk-based design via Alcami, the leading fully integrated end-to-end CDMO that utilises automated equipment, can bring the principles of Quality by Design into the early clinical development of manufacturing processes that drive right-first-time and expedience into the clinic.