This has led to rapid growth in the aseptic processing market, notes Thomas McGrath, VP, Global Quality, Manufacturing at PCI Pharma Services, which, increasing from $10.63 billion in 2020 and witnessing a CAGR of 7.9% (2021–2031), is expected to reach a value of $24.36 billion by 2031.1

With the pharmaceutical industry’s growing pipeline of biologics, the need for technically advanced manufacturing and specialised packaging support has grown considerably.

Global contract development and manufacturing organisations (CDMOs) such as PCI Pharma Services (PCI) are playing a vital role in terms of fulfilling industry needs and providing the expert capabilities and scalable capacities required for the development, manufacture, packaging and supply of these life-changing drug products for patients.

PCI Pharma Services: acquire, invest, grow

In response to the evolving industry landscape and as part of PCI’s global strategy to increase our sterile fill-finish capabilities, and help to alleviate the worldwide capacity shortage for sterile drug manufacturing and packaging, we continue to invest and grow our service offering through acquisition and investment in state-of-the-art technology and our people.

In December 2021, PCI acquired Lyophilization Services of New England (LSNE), a premier CDMO headquartered in Bedford, New Hampshire, US.

The acquisition was a key step for PCI as LSNE expanded the breadth of our services as a global CDMO, building on our expertise in specialty manufacturing, clinical trial supply and pharmaceutical packaging.

PCI now offers integrated large and small molecule solutions for our clinical and commercial clients, including global manufacturing capabilities in complex formulations, high potency, sterile fill-finish and lyophilisation.

Enhancing our integrated development to commercialisation-scale sterile fill-finish offering, we are investing more than $100 million at our Bedford campus. Using state-of-the-art isolator technology including high speed, large volume sterile fill-finish lines, this investment will deliver new facilities, capabilities and increased capacity.

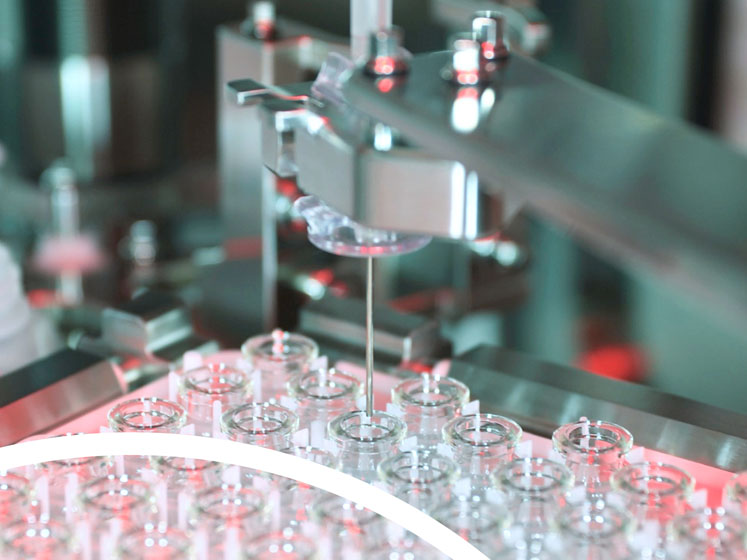

Aseptic filling

Administered parenterally to patients, products such as vaccines and other biologics require specific and unique production processes to optimise both particulate and bioburden control, all while ensuring uncompromised sterility throughout the manufacturing process to maximise patient safety.

This has led to the development of aseptic transfer and containment methods to protect drug products from contamination for clinical and commercial-scale sterile injectable products.

As a result, the industry is looking for advanced ways to improve efficiencies, reduce costs and increase sterility assurance, with robotic processing gaining huge popularity for the primary filling of ready to use (RTU) containers such as vials, syringes and cartridges.

Robotic aseptic fill-finish technology and the use of isolator-based barrier systems are emerging as being key to keeping pace with these requirements … and PCI is leading the way by investing in this cutting-edge technology to further enhance our global sterile fill-finish operations.

Robotic aseptic platforms at PCI

Complementing our global sterile fill-finish and lyophilisation manufacturing capabilities across North America and Europe, PCI has invested significantly in state-of-the-art robotic technology platforms at both our San Diego (CA, US) and Melbourne (Australia) facilities.

These technologies are positioned at locations where a high volume of early phase clinical trials take place and also allow our clients to benefit from the 43% tax rebate incentive for clinical trials conducted in Australia.

Utilising the latest Microcell and SA25 technologies, we deliver flexible aseptic fill-finish solutions for both small and larger-scale production runs across a variety of dosage forms — including vials, prefilled syringes and cartridges for use in autoinjectors — to help meet our clients’ needs in terms of delivering products to patients safely and efficiently.

Our investment in multiple robotic technologies provides a scalable solution for our clients, supporting all clinical drug product requirements from Phase I trials and beyond.

The Microcell platforms in San Diego and Melbourne offer fully automated gloveless filling, which is done through closed robotic isolator technology that provides both small batch flexibility and standardised manufacturing.

The fast changeover times and agility of the technologies make them suitable for the production of both personalised medicine batches and clinical trial supplies, thereby delivering true speed to patients. Superior drug product quality is ensured through advanced automation, removing the need for operator intervention during the filling process and limiting product contact.

Importantly, the Microcell technology can fill up to 1200 units per batch with fill volumes ranging from 1.0–50 mL.

Providing a scalable aseptic solution to support clients progressing through the clinical lifecycle towards commercialisation, the SA25 Aseptic Filling Workstation is a larger-scale, gloveless isolator-based filling technology that offers the batch production of up to 20,000 units and supports fill volumes of 0.2–50 mL.

It provides flexible and standardised manufacturing with the ability to aseptically fill multiple delivery device formats, including vials, syringes and cartridges.

For both the Microcell and SA25 technologies, precise and programmable robotic functions cover all aspects of the fill process, including isolator leakage tests, VHP sterilisation of the container closures, filling into the CCS of choice, capping and batch delivery.

They are also compatible with RTU containers and closures, removing the container and closure preparation stage and adding speed of delivery to a quality and sterility assured drug product.

Robotic advantages for our clients

Speed and accuracy: Expediting the filling process with automation, while also increasing accuracy, the robotic platforms with high-precision dynamic peristaltic pumps ensure accurate fill volumes with minimal product losses.

This is a significant benefit to our clients, who are often developing life-changing high-value drug products with the need to progress through the clinical pipeline with efficiency and speed.

Minimising product losses not only conserves valuable drug product and therefore reduces cost, but ensures that our clients’ clinical supply needs are met and key milestones are achieved as the product progresses towards commercialisation.

Quality assurance and sterility: With a robot performing the processes in a recipe driven, validated system and utilising single-use parts, presterilised flow paths and RTU containers, multiple sources of risk are eliminated, including

- cross-contamination

- human error

- electromechanical filling and closure activity failures

- environmental control failures

- cleaning and setup errors

- product loss.

Using press-fit vial closures with integrated rubber stoppers not only reduces the risk of particle contamination, it also simplifies the manufacturing process. The press-fit closures comprise a one-step application that presses closures on top of the vials compared with the traditional two-step process of stoppering and aluminium crimp capping.

All this means that our clients are able to move more rapidly through the clinical stages and provide safe, life-changing therapies to patients. Flexibility: Robotic technologies are designed for maximum flexibility while maintaining high aseptic processing rates.

Meeting the need to fill many different products and process multiple projects with minimal changeover times between batches provides significant speed benefits and allows us to better support clients who have urgent drug product supply needs.

Seamless sterile solutions

Our clients aim to accelerate their sterile drug development lifecycle and seek readily available capacity, reducing time to clinic and, ultimately, commercial launch.

They seek experienced partners who are able to meet their fill demands with state-of-the-art technology to minimise the risk of failure — particularly in the early stage development of complex, high value products that can be difficult to handle.

Any failure during the aseptic fill-finish process can lead to product degradation, which affects a drug’s efficacy and safety. The importance of mitigating risk cannot be overstated: failure in a batch can mean significant time delays and serious cost consequences.

It may also put the entire timeline in jeopardy, delaying clinical trials, launch plans, commercialisation and, ultimately, impacting patient lives. The addition of these innovative robotic aseptic fill-finish platforms in our San Diego and Melbourne facilities enhances our renowned sterile and lyophilisation capabilities across our global network.

These advanced technologies don’t just expedite the filling process with automation; being able to pivot between filling different sterile medications into multiple dosage formats brings even broader sterile fill-finish solutions to PCI clients throughout the entire drug product lifecycle — bringing therapies to market with increased speed and safety.

Providing integrated end-to-end solutions and helping to reduce supply chain complexity and risk, our clients can also access our global network of expert secondary packaging, labelling and distribution solutions, leveraging the benefits of working with a single supplier.

Combining our expertise in sterile fill-finish manufacturing with specialist biologics packaging, labelling and cold chain distribution provides a valuable end-to-end solution, simplifying the supply chain while delivering time and cost efficiencies.

Reference

- https://bisresearch.com/industry-report/aseptic-pharma-processing-market.html.