Steel quality is the summation of how well a steel meets its specified chemistry, the cleanliness of the steel or degree to which it is free of impurities or inclusion, homogeneity of the microstructure, grain/ carbide size, and in some instances if it meets the mechanical requirements for that particular steel. In the design and manufacture of tablet compression tooling, nothing is more important than the quality of the materials being used. The best manufacturing principles, maintaining the tightest tolerances, will result in tool failure if the initial steel quality is poor. Steel quality is the fundamental building block upon which all successive value-added steps are laid.

Quality of steel should be seen as an inherently quantifiable attribute that is used to determine a steel’s ability to perform its designed function without limitation due to internal flaws or large variances in microstructure or homogeneity. Process control in all areas of steel production and refinement will determine a steel’s quality. Heat treatment, while not a determinant in the initial quality of steel, must be carried out properly to ensure success; a quality steel poorly heat treated is also doomed to failure.

Typically, all non-powder metal steels are produced in the same way, with material charges added to a furnace and melted; the melted metal is called A HEAT. Chemistry of the heat is checked and adjustments (alloy additions) are made to ensure that the chemistry falls within the specified range. Once the chemistry is correct, the heat is tapped, slag is removed, and the heat is poured into ladles. Then the steel in the ladle is cast into molds. After solidification in the mold, the ingots or blooms are reheated to rolling temperature and rolled into a bar or plate for use in the production of tooling. Powdered metals, on the other hand, are produced by compacting very fine powdered metal (densification) using high temperature and pressure. After densification, the resulting product is a fully dense billet that is then rolled into bar or plate. There is very little physical distinction between a powder metal bar and a traditionally cast bar, except the microstructure of the powder metal is typically of a finer grain structure and more homogeneous. This control over carbides and grain size enhances the mechanical properties of the steel and allows some unique chemistries not available to traditional casting. Due to the manufacturing process requirements, powder metals are more expensive than equivalent steels traditionally cast. Additional steps can be taken before and after the initial pouring of steel, prior to rolling, to increase the cleanliness of the traditionally cast steels.

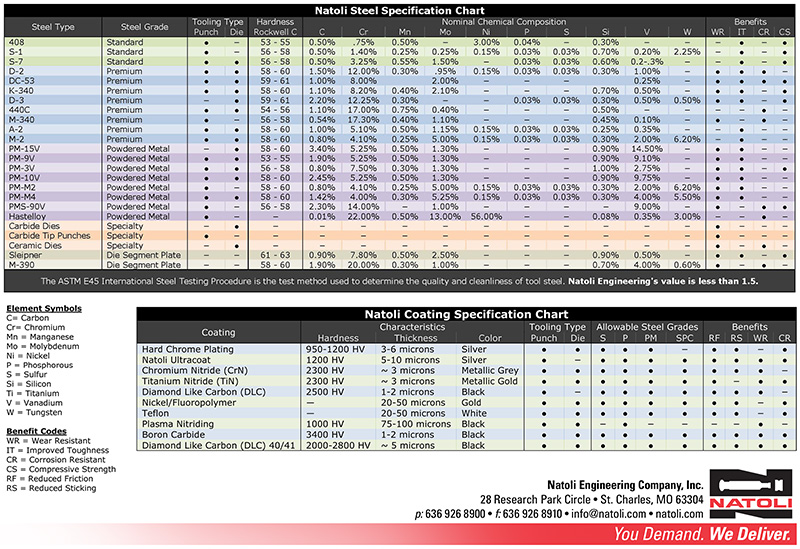

Natoli Quality Steel & Coatings Chart

VACUUM INDUCTION MELTING (VIM) melts the “material charge” in a vacuum before pouring; this process reduces the partial pressures of gas in the melt, preventing the formation of some oxides and producing cleaner steel.

ELECTROSLAG REMELTING (ESR) takes a cast ingot prior to rolling and places it into a chamber with reactive molten slag that has high current electricity passed through it, melting the ingot. As the ingot melts, the liquid metal passes through the reactive slag, impurities are removed, and solidification takes place where the liquid metal is chilled by the chamber wall. The solidification rate is much higher than the casting process, and the amount of segregation is reduced. The process continues until the entire ingot has passed through the slag and re-solidified on the opposite side. ESR produces very clean homogeneous steel with a refined cast structure.

VACUUM ARC RE-MELTING (VAR) is similar in result to ESR, but the ingot is melted by an arc under vacuum. The vacuum lowers the partial pressure removing any gases within the ingot, leaving a cleaner ingot with a homogeneous microstructure and little segregation due to the higher solidification rates.

During rolling, the steel ingot is reduced in cross section and elongated to produce the wrought bars used to manufacture tablet compression tooling. This reduction helps reduce segregation and refine carbide and grain size. Steel with a fine grain size and small, well-dispersed carbides will perform better than steel with larger grains and coarse carbides; the larger the reduction the greater the refinement. Tight control over the temperature and amount of reduction per pass, must be maintained during the rolling process to ensure that voids or cracks do not “open up” during rolling.

Analysis of the bar’s chemistry and microstructure after rolling provides assurance that the bars were produced within tolerance; the steel mill will provide a certification for that heat. End users of these finished bars should perform their due diligence by having sample bars tested randomly and analyzed by an independent lab to ensure they meet the specification. During this quality assurance, at the mill or the end user, we quantify the cleanliness of the steel through image analysis, either comparatively with representative standards or with software designed to sort and classify inclusions. Several standards exist worldwide (ASTM, DIN, JIS, ISO) to make sure steel cleanliness and quality measurements are consistent and defined. Because steel quality is something that can be quantified and compared between vendors it should be the basis for making informed judgments about the tools you purchase. Don’t allow a salesman to tell you about the quality of their steel; ask them to show you!

Natoli Engineering requires all steel to be Electroslag Refined (ESR) to ensure cleanliness and adheres to a strict internal carbide size and distribution standard. In addition to seeking the highest quality steel, we quarantine all incoming material until an outside laboratory verifies that all specifications and standards were met: ASTM A681-06 or manufacturers’ specifications for chemistry and ASTM E45 Method D (Low Inclusion Content) to quantify cleanliness.