Biologic-based drugs are an increasingly important part of the portfolio growth strategies for pharmaceutical and biopharmaceutical companies. As the number of commercial products and pipeline candidates grow, key issues facing the industry include the current and future state of biomanufacturing capacity, the availability of that capacity and technologies impacting upstream and downstream bioprocessing.

Since the approval of the first recombinant therapeutic antibody (OKT3) in 1986, biopharmaceutical products have become a larger percentage of overall pharmaceutical company revenue. In 2018, the sales of the top five selling recombinant proteins (Humira, Keytruda, Herceptin, Enbrel, Avastin), all antibody products, totalled more than $4 billion.

The compound annual growth rate for antibody product revenue, which includes naked monoclonal antibodies, Fc-fusion proteins, antibody fragments, bispecific antibodies, antibody conjugates and other antibody related products, was approximately 20% from 2004 to 2014.

However, this growth has slowed to the mid-teens in the recent years owing to the maturation of many products and emerging alternative therapeutic modalities. Also, it is difficult to sustain such growth rates as the overall market size increases.

To provide context around this growing segment of the pharmaceutical market, the proprietary bioTRAK database of biopharmaceutical products and manufacturing capacity estimates that there are nearly 1400 biopharmaceutical products in some stage of clinical development in the United States or Europe.

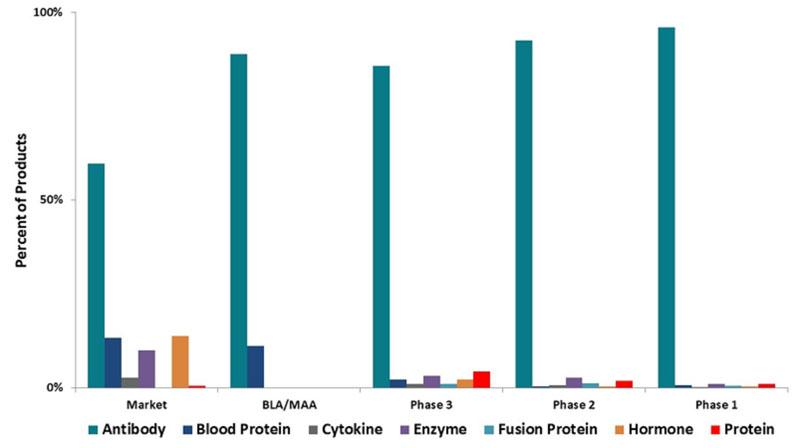

The majority of these products, nearly 85%, are produced in mammalian cell culture systems. We evaluate the distribution of mammalian products by product type and phase of development to further refine the biopharmaceutical manufacturing market. Figure 1 shows the distribution of product types, including antibody products, defined previously, blood proteins, cytokines, enzymes, fusion proteins, hormones and other recombinant proteins by phase of development.

Antibody products are the dominant commercially marketed product type at nearly 60% and are the largest product type for all phases of development, with the early stage pipeline consisting of almost all antibody products. It is important to note that many of the early commercial biopharmaceutical products, such as growth hormones, insulins and interferons, are produced in microbial systems.

Figure 1: Distribution of mammalian products by product type and phase of development

Whether commercially approved or in development, each of these products needs access to mammalian production capacity. For current commercially approved biopharmaceutical products, the future demand is estimated from each product’s reported annual sales data, along with estimates of each product’s future growth rates.

Our future product growth estimations take into consideration a product’s age, as sales growth typically slows as a product matures, whereas newly approved products often do not reach full market penetration for several years.

The projected treatment population size is estimated based on price per milligram and sales. Combining the population with the yearly per patient dosing, we forecast the kilogram quantities required to meet demand for each product for the next 5 years.

These kilogram quantity forecasts can be converted to litre quantities for each product using cell line expression level and overall purification yield estimates. These estimates are based on industry benchmarks at the time the product was being developed and the maturity of the company developing the process.

For example, the commercial process for a product launched more than 10 years ago will likely have a lower expression level assigned in our forecast algorithm than a product currently in clinical development. For products in development, future commercial demand is estimated based on the market penetration of currently approved products or proxy products with similar indications.

Additionally, for products in development, we employ a phase-based commercialisation probability assumption when calculating future demand.

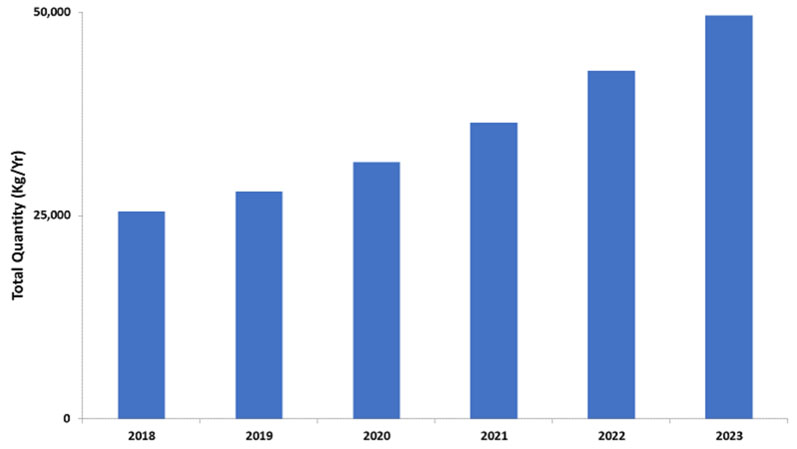

Figure 2 shows the projected kilogram quantities of product needed to meet annual commercial and clinical demand for all product types produced using mammalian production systems. In 2018, approximately 25 metric tons of product were required. As more products enter the pipeline and products in development receive commercial approval each year, the overall kilogram requirements needed to meet product demand increase from approximately 25 metric tons in 2018 to nearly 50 metric tons in 2023.

Figure 2: Estimated quantity of bulk kilograms needed to meet product demand

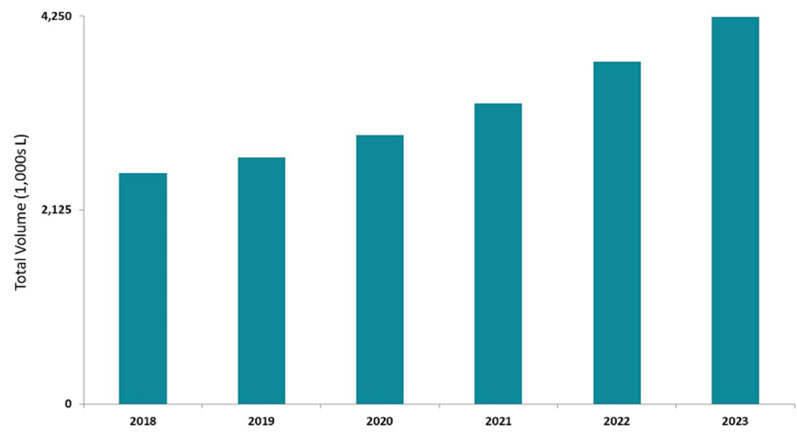

Figure 3 shows the projected volumetric capacity needed to meet annual commercial and clinical demand for all product types produced using mammalian production systems. In 2018, the annual volumetric requirements were just over 2500 kL, whereas in 2023, the volumetric requirement is projected to be slightly more than 4200 kL, a 5-year growth rate of 11%.

Figure 3: Estimated volumetric capacity needed to meet product demand

As with any forecasting model, our assumptions are based on the mostly probable scenarios and include estimations for biopharmaceuticals which are being developed for certain large patient population indications such as Alzheimer’s disease or broad cancer treatments like PDL/PDL-1 checkpoint inhibitors.

Should several of these large-demand products obtain regulatory approval and adequate reimbursement by healthcare oversight organisations (such as US Pharmacy Benefit Managers, the UK’s National Institute for Healthcare and Excellence [NICE]) or become part of a managed entry agreement between a company and public payer of a social or national health insurance system, a significant increase in demand for manufacturing capacity could occur potentially leading to a serious capacity shortage.

Conversely, there are other manufacturing trends that could result in a decrease in demand for some biopharmaceutical manufacturing capacity. Among these are the industry’s increased focus on orphan indications, a shift from full length naked antibodies to alternative antibody formats and more potent products (antibody drug conjugates [ADCs] or bispecific antibodies) which would require lower doses.

Given the projected increase in volumetric demand over the next 5 years, the industry is cognizant of the inherent volatility of production capacity forecasts. There is always a degree of uncertainty in balancing the demand and supply equation owing to production problems, market demand fluctuations over time, regulatory and reimbursement issues, and competitive factors.

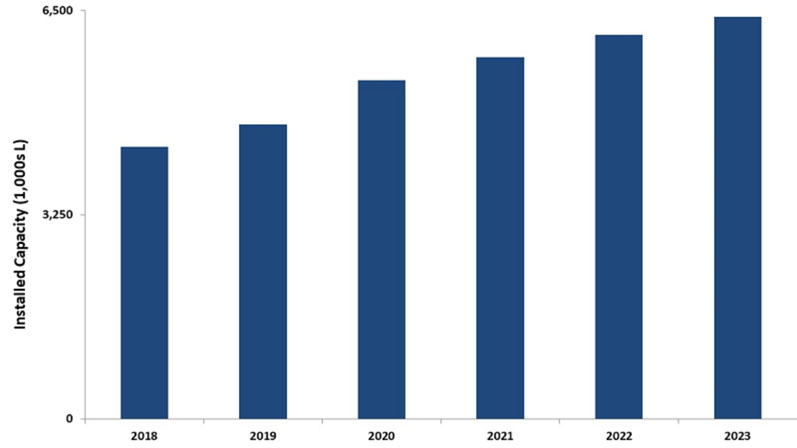

To understand how the industry is positioned to meet these product demands, we estimated the 2018 mammalian cell culture supply to be nearly 4400 kL and predict it to grow to nearly 6400 kL by 2023, a 5-year growth rate of 8% (Figure 4). However, not all capacity is equally available throughout the industry.

In 2018, product companies — that is, entities focused on product development — controlled more than 70% of the installed mammalian cell culture capacity, whereas hybrid companies — those that are developing products but also sell or make available any excess manufacturing capacity — and CMOs controlled significantly less capacity.

The distribution of capacity changes slightly in 2023, with product companies controlling 65% of the installed capacity, CMO capacity increasing to 6% and hybrid companies remaining stable with a 1% increase.

Figure 4: Mammalian manufacturing capacity

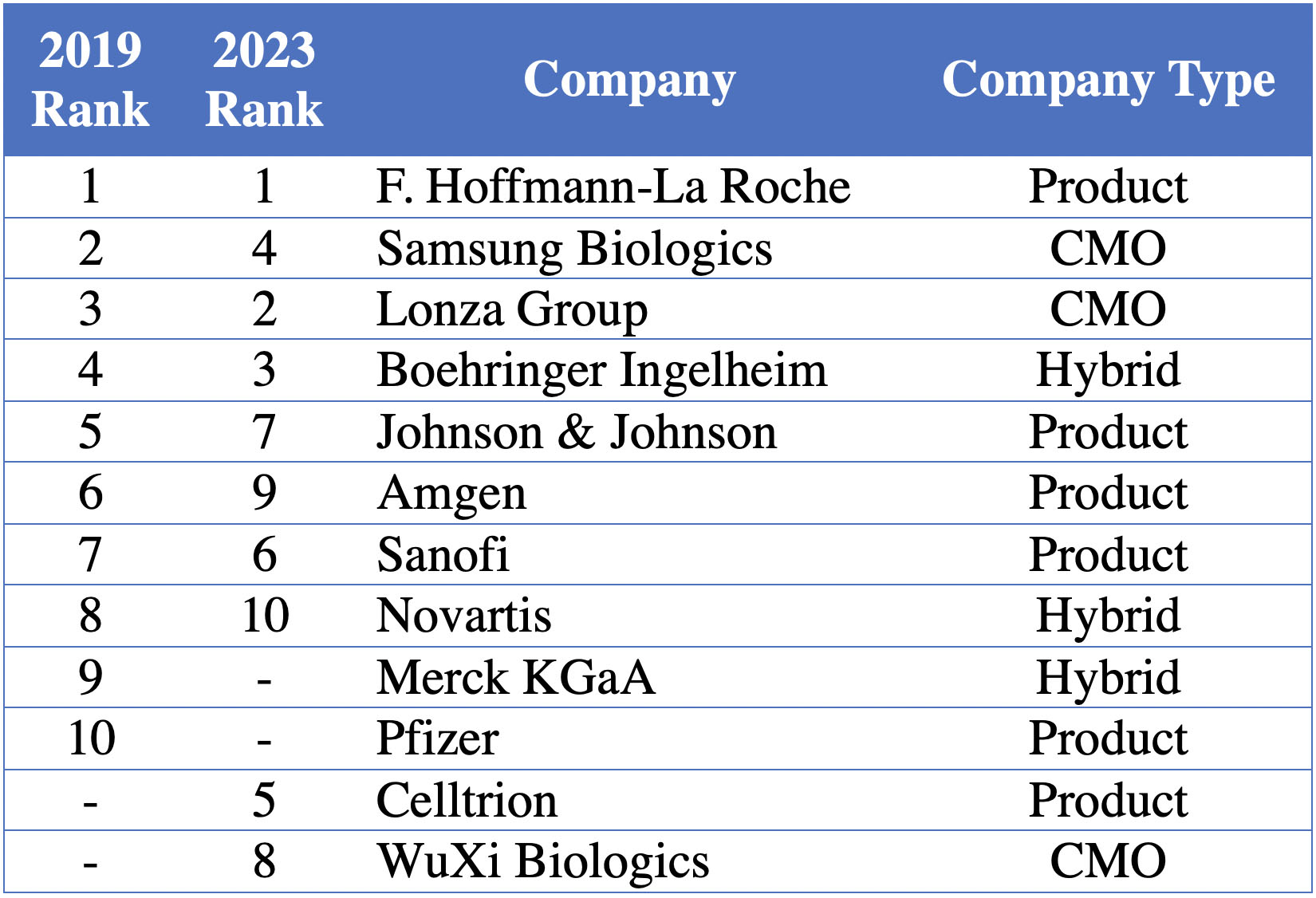

Although product companies control the majority of cell culture capacity, the distribution of this capacity is highly concentrated within 10 companies (Table I). Capacity for companies not ranked in the top 10 is distributed among nearly 130 companies in 2019 and nearly 135 companies in 2023.

Table I: Control of manufacturing capacity

Currently, almost 65% of the capacity is controlled by 10 companies; in 2023, this changes to less than 60%. Based on substantial capacity investments, Celltrion and WuXi Biologics will displace Merck KGaA and Pfizer from the top 10.

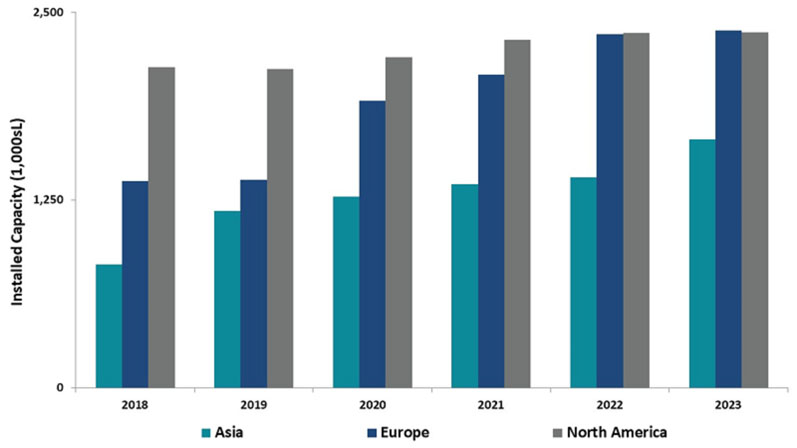

Figure 5 shows the geographic distribution of the manufacturing facilities. In 2018, nearly half of all mammalian capacity is located in North America, followed by Europe and Asia. During the past 5 years, there has been modest capacity growth in North America and Europe, with significantly greater growth in Asia.

By 2023, with significant growth rates projected in Asia (~9%) and Europe (nearly 15%), North America and Europe will have equivalent capacity. The capacity growth in these areas, particularly in Korea, Singapore and Ireland, are likely to be derived from government incentives and tax advantages, among other factors.

Figure 5: Geographic distribution of capacity

As described earlier, different products require different capacity. For example, the 2018 kilogram demand for the top five selling antibody products totalled nearly 6.8 metric tons. The demand for the more than 90 remaining marketed antibody products combined was approximately 15 metric tons.

For products still in development, in a best-case commercial scenario in which market success and maximum market penetration are assumed, projected demand for nearly 60% of these products in development is expected to be less than 100 kg per product per year.

Only 10% of the products, such as those for Alzheimer’s disease, Parkinson’s disease, diabetes and, possibly, some coronary heart disease or atherosclerosis products, are projected to require more than 750 kg per year.

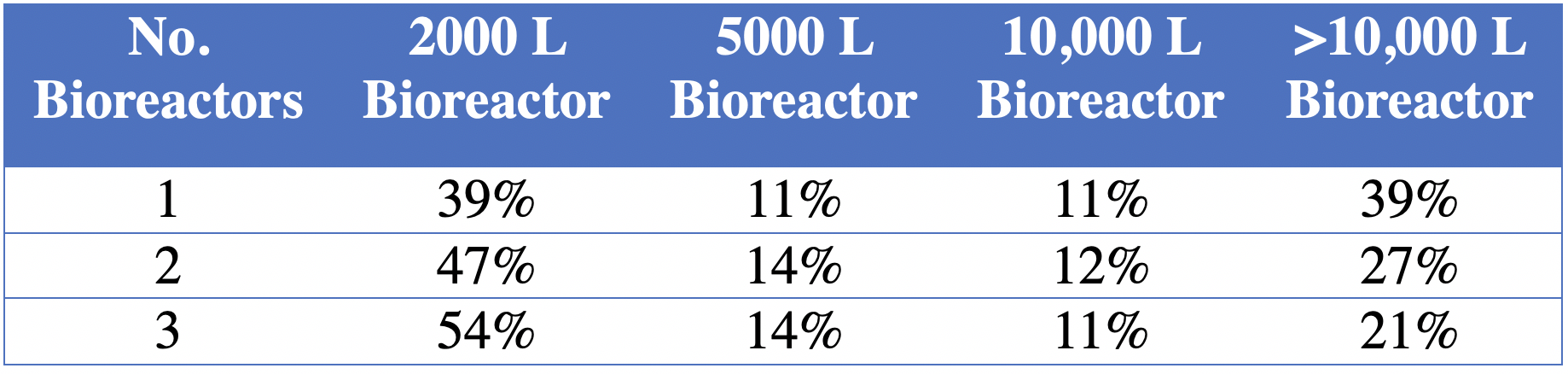

A closer review of future projected commercial manufacturing demands for products in Phase II and Phase III clinical development reveals that half of the products could be met with a single 2000 or 5000 L bioreactor — assuming 18 batches per year per bioreactor with a 90% success rate for batch manufacturing (Table II).

However, this does not mean that large-scale capacity is no longer needed. Our model predicts that the remaining half of products will need bioreactor capacities of 10,000 L and greater to meet the forecasted demand. Increasing the number of bioreactors increases the manufacturing capacity and not surprisingly causes a shift in the percentage of products whose development can likely be met.

As an example, a single 2000 L bioreactor is capable of manufacturing 39% of the products in Phase II and Phase III, whereas a trio of bioreactors at this scale would be capable of manufacturing more than half (54%) of the products in development.

Table II: Percentage of product demand met by bioreactor scale

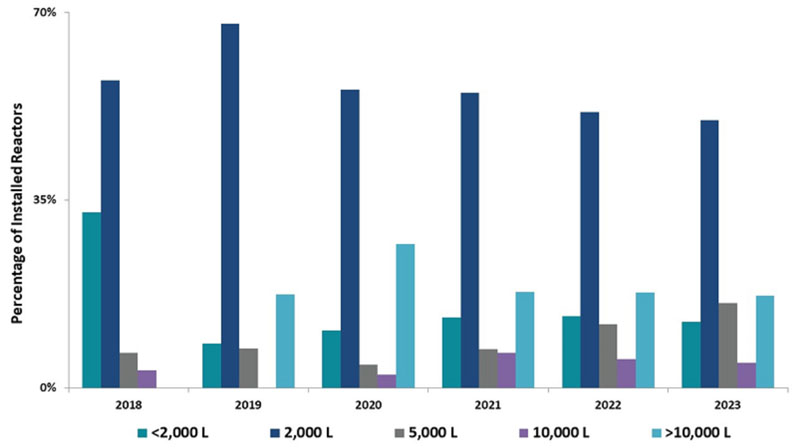

If we analyse the cumulative number and scale of bioreactors coming on line between 2018 and 2023 at the <2000, 2000, 5000, 10,000 and >10,000 L scale (Figure 6), it is evident that the majority of the bioreactors projected to come on line are 2000 L.

Nearly 20% of the bioreactors are at a scale of 10,000 L or greater. Manufacturers understand the capacity demand scenarios and are installing capacity to meet these anticipated demands.

Figure 6: Percentage and scale of future bioreactors

Overall, the biopharmaceutical industry will continue to have strong growth for the foreseeable future … and antibody products will be the dominant driver of this growth. Installed capacity is currently able to meet the manufacturing demand for these products, but control and location of capacity can affect accessibility.

The majority of capacity is product based, rather than CMO based, which could make it difficult for companies without capacity to access it at the right time and under the right terms. North America currently has the greatest percentage of installed capacity, but Asia and Europe have seen a surge in new capacity installation.

Although capacity will increase during the next 5 years, demand for capacity will increase at a slightly faster rate allowing for some short-term loosening of capacity constraints; but, after 2023, capacity tightening may occur. In recent years, we have noted that the industry was experiencing some capacity constraints at the clinical scales owing to very high clinical demand and the industry has responded in kind with a wave of facility expansions.

The type and scale of capacity being installed will also be important as the demand for half of the products in mid-to-late stage development can be met with 5000 L of capacity or less, whereas the remaining half will need more capacity to meet future demand.

With new bioreactor installations reflecting the demand profile, we are watching how the industry is responding to these demands for capacity as it is critically important to ensure that current and future products are available to patients.

This article has been adapted from the 2019 CPhI Annual Report.