The tablet is the most common solid dosage form. Consumers find tablets appealing for their various sizes, shapes, colours, designs and coatings, but can also often find them hard to swallow. Appearance and user experience can quickly determine whether a consumer will purchase a tablet product again or continue to take the product as prescribed, therefore, it is important for tablet manufacturers to consider the consumer when designing a tablet and the required tooling.

Consumers must perceive that a tablet is easy to swallow, without any undesirable taste. A tablet manufacturer can influence acceptance by producing tablets that appear easier to use. Tablet design drives much of a tablet's visual impact and design features—such as a smooth tablet shape—can improve a product's appeal and influence consumer preference. This article discusses the limitations of the flat-face, bevel edge (FFBE) tablet design and the benefits of the flat-face, radius-edge (FFRE) design in encouraging consumer acceptance.

Because a tablet's design can so strongly influence consumer acceptance, a company’s marketing department often provides significant input as the company makes design and coating decisions. Companies should also include production personnel in these decisions because they are responsible for delivering the final product. Their experience and expertise can greatly reduce production costs and minimise problems because some tablet designs can result in difficult manufacturing challenges, higher tooling costs and tablets with suboptimal physical properties.

FFBE tablets

Companies often develop FFBE tablets to improve tablet quality and reduce production costs. The FFBE tablet design became popular early in the development of rotary tablet-press manufacturing, because it offered a significant improvement over the flat-face tablet design. Due to powder leakage at the interface of the flat punch tip and the die wall, flat-face tablets can suffer from weak edges that are prone to chipping and excessive friability.

Adding a bevel edge to the tooling was a very simple fix for a tooling machinist and allowed the punch tip to push the formulation toward the die's center during compression, making stronger tablet edges than the flat edge design allowed.

Over decades, the FFBE design has become very popular in the tableting industry, but limitations exist on the amount of compression force that you can use with FFBE tooling without risking tip damage.

FFRE tablets

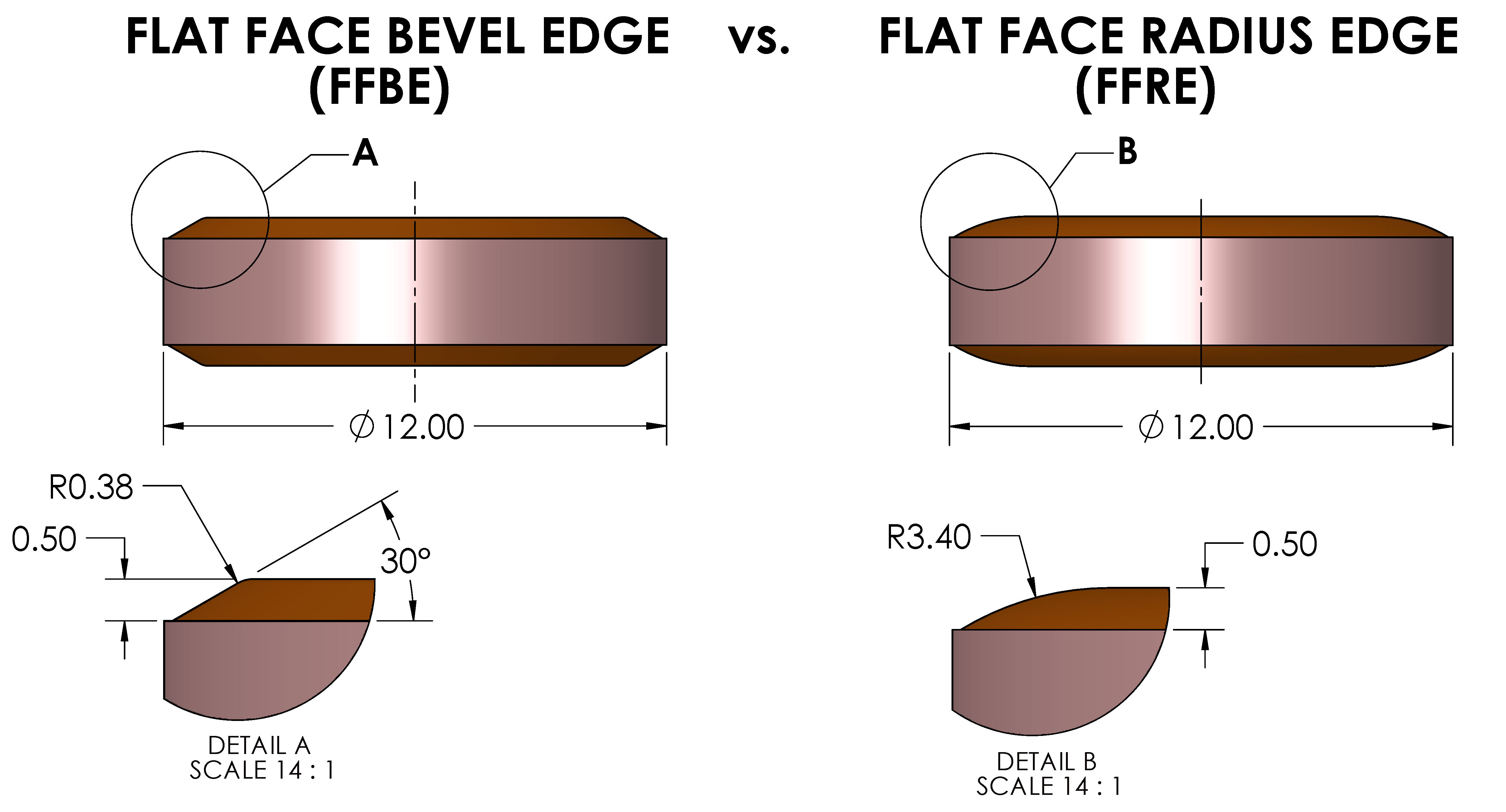

Compared to the FFBE design, the FFRE tablet design offers smoother edges, providing greater consumer acceptance (Figure 1).

Figure 1: The FFRE tablet design offers smoother edges than the FFBE design, providing greater consumer acceptance

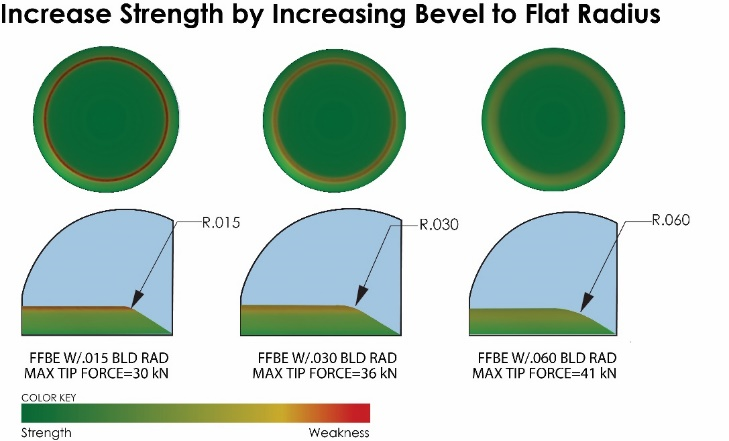

Additionally, a finite-element engineering analysis comparing FFBE and FFRE tablets of the same size indicate that the maximum compression force allowed for FFRE tablets is significantly higher than that on FFBE tablets (Figure 2). This offers manufacturers the option of using additional compression force to increase tablet breaking strength with no associated risk to the tooling or tablet press and without requiring a formulation change. Tablets produced by high compression force are also less prone to edge erosion, sticking and picking.

Figure 2: As the bevel to flat radius increases, the punch tip is strengthened therefore allowing a higher compression force rating

In the FFRE design, although the differences are sometimes visibly imperceptible, the tablet edges are smoother and consumers have the impression that the tablet has a softer appearance and a pleasant mouth feel. The impression of a comfortable mouth feel can reduce the anxiety that elderly patients often experience with difficult-to-swallow tablets.

These observations are important to providing the first-impression appeal that is essential to establishing a successful product brand. A growing number of companies are manufacturing their uncoated flat-face tablets with FFRE rather than FFBE designs. This trend warrants consideration by companies seeking to produce quality tablets with greater consumer acceptance.