In all national pharmacopoeias, drinking water is the basis for producing water for pharmaceutical purposes. Now, what was long prohibited in the EU has been a reality for the past two years: water for injection (WFI) can also be produced using a cold membrane process.

The challenge: although there are official requirements for safe WFI, they do not apply to the manufacturing process. So, will the cold membrane process be able to establish itself in the long-term?

Drinking water invariably contains certain substances that must be removed for pharmaceutical purposes. The international pharmacopoeias draw a distinction between two levels of pharmaceutical water: purified water (PW) and water for injection (WFI).

Although PW is primarily used as a base material prior to treatment in subsequent stages and to produce pure steam, WFI is intended for use in injection and infusion solutions for parenteral applications. The manufacturing processes used for PW and WFI are prescribed by the respective pharmacopoeias.

Until 2017, the European regulations differed considerably from comparable pharmacopoeias, such as those in the US or Asia: distillation was the only process permitted in the EU for the production of WFI.

Hot is out, cold is in … right?

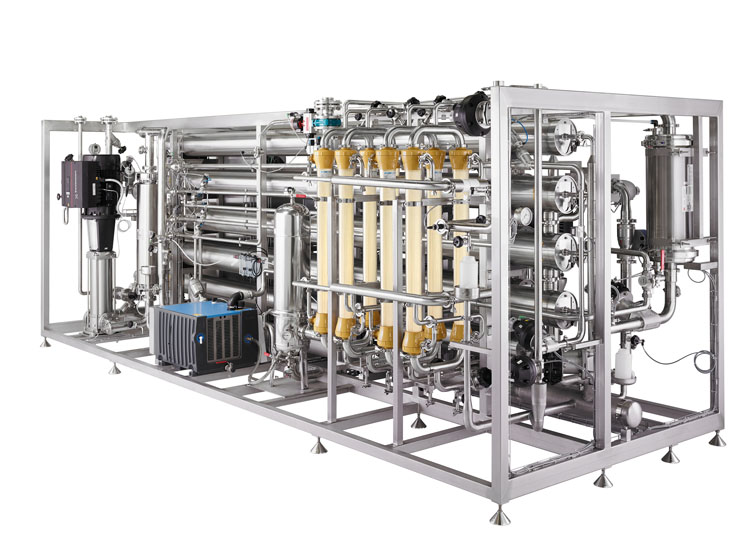

The revision of WFI monograph 0169 in the European Pharmacopoeia can rightly be considered to be a minor revolution: since it came into force on 1 April 2017, alternatives to distillation have also been permitted in Europe, including “cold” membrane processes (reverse osmosis and electrodeionisation) in combination with an additional ultrafiltration step.

Compared with distillation, the membrane processes are economically and ecologically more efficient as they eliminate the need for additional plant, the energy required to generate hot steam and any associated costs. However, a final market decision regarding the optimal manufacturing process has not yet been taken.

Accordingly, pharmaceutical companies are currently testing a variety of cold membrane processes. As a rule, changes in the pharmaceutical industry take time; after all, patient safety is at stake. The regulatory requirements for WFI as a product are correspondingly stringent.

Although authorities such as the EMA and WHO, as well as professional organisations including the ISPE, are intensively focusing on the topic, there are still no detailed regulations or recommendations for a uniform production process.

However, there’s one point that almost everyone agrees on: a risk-based approach to plant planning and operation is essential. If the current pilot projects deliver stable and cost-efficient results, there is nothing standing in the way of widespread application.

Taking a risk-based approach

Essentially, the WFI production process that’s best suited for individual pharmaceutical manufacturers depends on the projected microbiological risk — a contamination event could have fatal consequences. Therefore, the key question is: how can optimal operational safety be achieved?

To ensure that the pharmaceutical water produced using a cold membrane process meets the required quality criteria, the potential risks of bacterial contamination must be assessed and minimised as far as possible.

At the beginning of the treatment chain, pretreatment is especially important; it removes substances from the water that could adversely affect the subsequent membrane processes or form deposits. The pretreatment processes used vary, depending on the substances initially present in the water, and can be installed in a sequential arrangement or in combinations.

To remove coarser particles from the water, the use of multiple filtration steps is recommended. Oxidative substances, micro-organisms and organic carbon (TOC) must also be removed from the water during pretreatment. Activated carbon adsorbs TOC, whereas micro-organisms can either be killed using oxidative chemicals such as chlorine or ozone, or rendered inert using UV radiation.

Sanitisation as a decisive factor

The subsequent softening of the drinking water prevents so-called “hardness formers” such as calcium or magnesium from forming insoluble compounds in the water. As an alternative to softening, the solubility limit of hardeners can be increased by means of chemicals referred to as antiscalants.

In some instances, operators must prove to the authorities that no antiscalants remain in the final product. Accordingly, softening the water with cation exchange resins is more advisable and reliable. That being said, softening also involves the greatest risk of contaminating pharmaceutical water. Therefore, hot-water sanitisation of the resin during production is recommended.

In the context of pharmaceutical water treatment, sanitisation is vital to minimise the risk of contamination in all stages of the process. This can be done using hot water or chemicals; although chemical sanitisation involves lower investment costs, it is only partially automated and less effective than hot-water sanitisation.

From RO to EDI to UF

The subsequent treatment step, reverse osmosis (RO), is exclusively intended to remove ions, particles, micro-organisms and other undesirable substances. RO always produces a certain amount of wastewater, which can be reduced to a minimum using process engineering solutions. Consequently, pharmaceutical companies can address aspects such as sustainability and resource-efficient production with the help of suitable facilities.

RO does not remove dissolved carbon dioxide (CO2), which increases the water’s conductivity. Membrane degassing based on air stripping is frequently used to remove free CO2. The procedure is comparatively simple and cost-efficient as it does not normally require the use of additional nitrogen or vacuum.

The continuous electrodeionisation (EDI) method involves a combination of membrane processes and electrodialysis — and can reduce the water’s conductivity to less than 0.2 µS/cm. The ultrafiltration modules, which are installed downstream, are used to remove endotoxins and bacteria, so that the water complies with acceptable limits.

The concentrate by-product created by ultrafiltration (UF) can then be recirculated upstream of the RO, so that no wastewater is produced. Regular monitoring of the transmembrane pressure and integrity tests yield insights into the condition of the filter modules and the effectiveness of the filtering.

Combining foresight and process know-how for success

Provided that each step in the WFI manufacturing process is optimally planned and co-ordinated, pharmaceutical companies can benefit from immense energy savings, not to mention an improved environmental balance — which is also why the amendment to WFI Monograph 0169 in Europe could not have come at a better time. In no other region are energy costs rising so rapidly.

At the same time, no other geography is as committed to achieving more sustainable production processes. If the cold membrane process proves to be a success here, transcontinental companies are sure to expand it to other areas as well.

But that’s still a long way off. The tasks at hand are to draw the right conclusions from ongoing projects, make adjustments as needed and organise the rollout to local sites. This will require the courage to invest in a new process. It will also require a healthy measure of foresight; as already mentioned, changes in the pharmaceutical industry take both time and a very thorough approach.

In addition, manufacturers will need a reliable partner who can not only supply the right equipment, but also has many years of process know-how and can support them with risk assessment, planning, validation and documentation. On this basis, investments in forward-thinking technologies will pay off, paving the way for the widespread and standardised use of cold membrane processes.