Continuous processing is a future goal for the industry. Process expert Nigel Fletcher, Foster Wheeler, examines the effects of converting a conventional batch process into a continuous one and the benefits that were realised once in production.

As with any branch of industry, pharmaceutical manufacture has to evolve and develop to meet modern standards and the needs of the market. One of the latest evolutions in pharmaceutical manufacture is continuous processing and, in particular, the conversion of traditional batch processes into continuous operation. A key driver for this change is the need to achieve cost savings, although the cost of manufacture is only one part of the total cost of a pharmaceutical product.

What has not been fully publicised are the other benefits that are delivered by continuous processing – the key ones being improvements in quality by design, sustainability and containment.

The plants Foster Wheeler has designed, built and started up provide excellent demonstrations of these additional benefits, as well as highlighting some innovative ideas that were developed during the design stage and that delivered other benefits.

Before addressing the example, it is important to understand what technology lies at the heart of continuous processing. If we consider any chemical process and apply chemical engineering principles, then the process can be ‘broken down’ into a series of operations. These include heat exchange, distillation, crystallisation and many others, including reactors. Many of these operations are carried out continuously in other industries and so their technology is well understood. The principal difference between these industries and pharmaceutical manufacture is one of scale.

The pharmaceutical industry manufactures at a scale far smaller than most other industries so the continuous technology that it must use also has to be realised at a small scale. However, one technology has seen a major change driven by the need for continuous processing. This is reaction technology, which has traditionally used the batch reactor but in continuous processing a new approach is required.

These new reactors are realised in several different forms including micro reactors, static mixer units and oscillatory flow units. The photograph of one of these illustrates the reduction in size compared with the traditional batch reactor. Figure 1 shows a novel reactor design that the Foster Wheeler team designed as part of one of its projects.

In the centre of the photograph, the horizontal cylinder is this special reactor. As can easily be seen, this is a radical change from the traditional batch reactor. This change has given rise to a number of benefits.

project case study

The reactor formed just one part of a six-step process that had to be converted from the original batch process to a single, streamlined continuous version. This required a team effort using Britest methodology to analyse every single reaction and unit operation for the whole process to establish exactly what was happening. This resulted in a large number of questions that the customer’s chemists had to answer by laboratory trial work. The results were critical to the success of the ultimate project and led to a restructuring of the process steps and how they could be engineered.

The first decision was to remove all isolation steps so that intermediates were not isolated, dried, drummed and transported to and from stores/warehouse. This decision allowed the design team to remove crystallisers, filters/centrifuges, dryers and pack-off systems except for the final product. This change was the first improvement leading to many benefits, as outlined in Table 1.

Table 1: Benefits gained from not isolating the intermediates

| The Change | The Benefits |

| Removal of crystallisers, filters, centrifuges and dryers | Reduced energy demand and improved sustainability |

| Reduced equipment count leading to less opportunity for contamination; therefore, improved quality by design | |

| Reduced drying steps leading to reduced heat degradation products; thus, improved quality by design | |

| Removal of pack-off systems | Reduced risk of intermediate exposure to the external environment; so, improved containment |

| Reduced risk of operators being exposed to the intermediates; so, improved occupational health | |

| Reduced use of packaging materials; so, improved sustainability and cost benefits to the manufacturer | |

| Reduced transfers to warehouse | Less energy required for transport to and from the warehouse and storage; so, improved sustainability |

| Reduced operator involvement in transfers; so improved occupational ergonomics due to reduced handling | |

However, the isolation of intermediates is an important step in many processes as the crystallisation, or precipitation, process purifies the material. This quality improvement step had to be replaced and the team determined that liquid-liquid solvent exchange would be the appropriate method. This decision gave rise to more research but, as a result, suitable solvents were identified, tested and, therefore, allowed the design to progress.

The research work of the customer's chemists had also investigated the conversion of the reactions from batch to continuous. This resulted in the selection of tubular reactors of a novel design, as can be seen in Figure 1. These reactors are much smaller than conventional batch reactors and can heat or cool the reaction as needed as well as allow the reactants to be brought together in a flexible manner.

Use of these reactors allowed for some ‘fine tuning’ on the plant when it went into production and this subsequently proved to increase product quality well beyond expectations. The reagents were fed to the reactors from bulk supplies to ensure continuous production was maintained. This also meant that, wherever possible, the solid reagents had to be dissolved so they could be simply metered into the feed section of the reactor. The use of continuous reactors also led to the discovery that the overall reaction time was considerably shorter compared with the same overall reaction time in a batch reactor.

The reactions are also more selective in the continuous reactor as the reactants are always brought together in optimal conditions. Table 2 summarises the significant benefits that were observed by the use of continuous reactors.

Table 2: Benefits from continuous reactors

| Observed Results | The Benefit |

| Reduced size of reactor compared with conventional batch type | Reduced spatial requirement and easier access (no platforming); so, reduced building requirements leading to improved sustainability |

| Heating and cooling needed only at start-up compared with batch units that require it every batch | Reduced energy requirement leading to improved sustainability |

| Faster reactions and better selectivity due to optimal profile reagent mixing and better controlled heating/cooling | Improved intermediate yield and reduced impurity giving improved quality by design |

As outlined above, one of the observed effects of moving to a continuous process was the reduction in heating and cooling requirements. There was no requirement to heat up a batch reactor and its contents to start the reaction and no requirement to cool it down after the reaction was complete. In fact, over the whole process, it was observed that there was a significant reduction in utility demand as the utilities were used only where changes or fluctuations to the processing were observed.

These reductions were monitored and recorded. The comparison is summarised in Figure 2, showing that the reduced utility demand is a very significant benefit that makes the continuous process both cost-effective and sustainable.

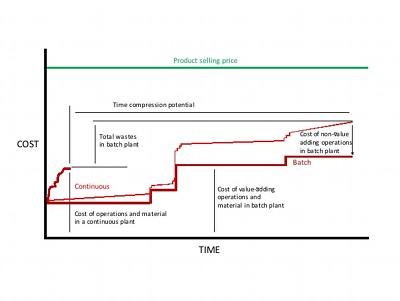

As has been demonstrated, the conversion to continuous processing delivered a significant number of benefits but there is one further area to discuss. As described above, the design removed many intermediate isolation steps and gave rise to faster reaction steps. These observations led to an analysis of the overall improvement in time for the whole process as illustrated in Fig. 3.

Fig 3: Cost against time comparison between continuous and batch processes

Eliminating non-value adding operations, including the need to dry intermediate batches, transport them to and from the warehouse, dispense them for the next stage and then repeat these operations for every intermediate saved a large amount of operating and processing time. This was then allied with improvements in reaction times amounting to tens of hours in some cases.

The combined result led to time compression for the whole process. The original batch process delivered product in approximately 18 months, whereas the new continuous process had final bulk product ready in less than two days.

In summary, the client's original purpose for the conversion of the process from batch to continuous was to prove that it was possible and to determine what other benefits could be realised.

Near the completion of the project, the team reviewed the whole of the design and installation to determine whether the desired benefits had been achieved. The conclusion was that they had been achieved in a spectacular manner. There was a major reduction in energy usage, the plant fitted into a smaller building and the elimination of work-in-progress demonstrated a highly sustainable process.

There were also improvements in product quality and improved impurity profiles indicating improved quality by design had been achieved. The reduction in manual handling and contained nature of the process achieved both improved containment and improved occupational hygiene.

So the overall conclusion was that the use of continuous technology resulted in the benefits of quality by design, sustainability, enhanced occupational health and reduced costs for the manufacturer.