Dec Group has announced its partnership with Kobelco Eco Solutions to launch a revolutionary mixer-type freeze dryer, RHEOFREED.

The launch comes in response to the limitations of conventional shelf-type freeze dryers and particularly their reliance on static drying and extended processing times.

RHEOFREED has been developed to drive efficiency, both economically and operationally.

Shelf dryers, long considered the industry standard, often suffer from slow and uneven drying performance.

The idea behind this new development was to revolutionise freeze drying by integrating controlled mixing into the process.

By integrating agitation into the freeze-drying process, RHEOFREED delivers a transformative leap in drying efficiency, uniformity and speed.

This breakthrough technology has the potential to redefine pharmaceutical manufacturing — poised to replace conventional shelf dryers and establish a new industry benchmark for performance, reliability and innovation.

Built on the proven Conical Dryer Blender (CDB) platform, RHEOFREED redefines freeze drying with a compact, efficient and contamination-free solution.

The system features a conical vessel with external suction ports and no internal moving parts.

By integrating cold-resistant materials and significantly enlarging vacuum piping (nearly five times the conventional diameter), it achieves deep vacuum conditions essential for freeze drying at -20 to -30°C.

The process begins by cooling the vessel and inserting a freezing nozzle.

Once a vacuum is achieved, liquid material is pumped in and instantly transformed into frozen powder via spray freezing.

The nozzle is then removed and the vessel rotates during drying to ensure uniformity.

After drying, the powder is discharged directly, completing the cycle with minimal handling.

Five game-changing features

The system employs a spray-freezing technique powered by an ultrasonic nozzle, enabling precise and efficient continuous transformation of liquid into frozen powder without the need for external freezing agents.

As a result, the lack of trays reduces both the physical footprint of the equipment and the time required for the freezing stage.

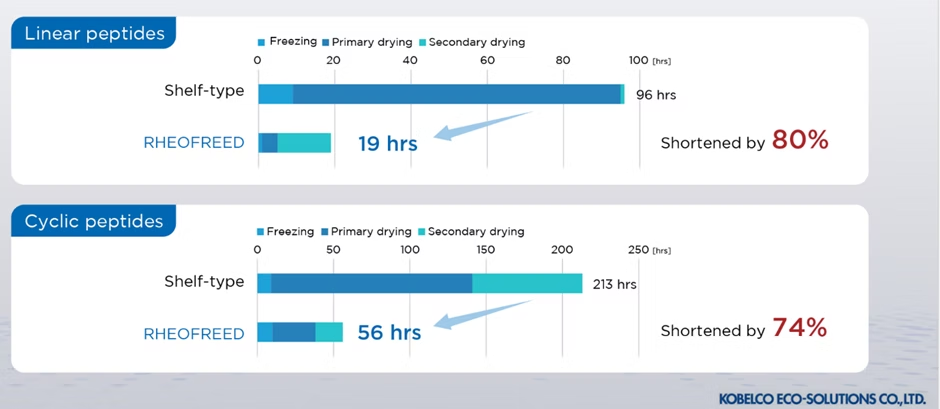

Tests show significant time savings for drying, with linear peptides showing an 80% reduction and cyclic peptides a 75% reduction in drying time.

The system also produces dry powder directly, eliminating the need for post-drying milling.

The overall process is greatly shortened, with preparation, drying, removal and cleaning all being streamlined.

Tailored for both small-scale testing and full-scale production, RHEOFREED is GMP-compliant with capacities ranging from 0.1 to 100 litres.

A compact 100 mL model is available for pharmaceutical clients working with limited sample volumes.