As one of the world leaders in the design and manufacture of ultra-hygienic high shear mixers, Silverson Machines is well placed to supply mixers for applications in both industries.

Not only do high shear mixers offer a range of advantages compared with conventional mixing equipment, Silverson's machines also come with a host of benefits, such as

- the ability to customise mixers to exact requirements

- the capability to scale-up from the laboratory to production with minimal or no reformulation required

- the variety of mixers in the product range.

In this article, Silverson Machines explains the advantages of their mixing equipment, along with examples of how it has benefitted customers in this industry.

Pharmaceutical company trials lab mixer then industrialises process

Part of the key to Silverson’s success — and that of our clients — is the accuracy with which we can predict the performance of our production-scale mixers based on laboratory trials.

There’s no point using a laboratory mixer that’s capable of speeds of 25,000 rpm or more if the results can’t be replicated in production.

That’s why our laboratory mixers are designed and built to the same tolerances as our production units; comparable rotor tip speeds and shear rates throughout our entire product range means scalable results ... time after time.

In a recent case, a multinational pharmaceutical company purchased two ultra-hygienic autoclavable-design inline mixers, successfully scaling-up a process that they first tested on a lab unit.

The company was developing a modified virus to be used to destroy cancerous tumours. To do this, they needed equipment that could finely disintegrate and disperse cells in water (using these cells to develop the virus).

The milling of the cells is the step that releases the virus, after which it can be extracted and then genetically modified to target and destroy cancerous tumours. The company contacted Silverson to test a lab mixer at the first stage of process development.

The results they achieved were very good and, to make the process safer, the company wanted to try a sealed unit lab mixer with assemblies that they could sterilise by autoclaving.

Silverson’s expertise extends to the design and manufacture of custom- built batch mixers for specific applications

After using the sealed units for further trials, they wanted to be able to control the amount of shear applied to the product during operation to get the precise results they were looking for.

They decided to buy a laboratory scale inline assembly as this provides intense yet targeted high shear to the small amount of material in the mixing chamber; inline mixers can also be used for discrete passes between two vessels, giving the ultimate in control as the product can be processed by a defined amount.

They purchased several L5Ms with inline assemblies for use on 2–5 litre batches. After each use, the inline assemblies were sterilised in an autoclave as they had done with their previous sealed units.

As the development process advanced successfully, the company needed to be able to work on a larger scale … but wanted to keep their procedure the same as it had been during the initial development stage with the lab mixers.

Silverson recommended an autoclavable 200 UHS. At 5000 RPM, the 200 UHS produces the same shear rate as that of the inline assembly at 8000 RPM.

This ensured that the mixer produced the same results as the lab mixers and, as a result, the process is now in industrial-scale production — using two autoclavable 200 UHS inline machines.

The mixers are used on 20 L single-use process bags. This highlights the advantages both of scalability within Silverson’s product range and our ability to design and manufacture custom-built highly specialised equipment.

As a result, the company was able to scale-up successfully from lab trials without intermediate testing, making a considerable saving in development costs.

High shear in-tank batch mixer built to pharmaceutical customers’ own specification

Silverson’s capabilities to customise mixers to suit exacting requirements were essential to another multinational pharmaceutical company who needed a mixer designed to meet their clean-in-place (CIP) and sterilise-in-place (SIP) requirements.

They were successfully using Silverson batch mixers to manufacture their products, but a review of their cleaning procedures indicated that they needed a mixer that could be used in a totally hygienic environment and in accordance with their updated CIP procedures.

To do this, the customer came up with their own mixer design and approached Silverson to see if they could make their concept a reality.

The customer was working on an API (active pharmaceutical ingredient) solution; so, protecting their operators was one of their key considerations.

Their design included a form of neck section between the motor and mixer that would enable them to wash the area between the motor and mixer flange and remove any product residue from this area.

The design also featured a removable motor; this would allow them to put the whole system into an autoclave to sterilise. As the operator would be wearing two pairs of gloves while handling the machine, the motor was specially designed so that they had an easy way to reconnect the mixer shaft to the motor.

Following a series of meetings, Silverson was able to create the exact mixer the customer wanted and they have since purchased three more mixers of this specification.

The largest capacity range from a single manufacturer

From laboratory to production-scale, Silverson Machines offers an unparalleled range of high shear mixers and the largest capacity range from a single manufacturer — with mixers able to process as little as 1 mL up to 300,000 L.

Silverson is continually adding new mixers and variants to this already substantial range to offer customers even more options in terms of batch sizes and processing requirements. Silverson has recently launched a new range of small-scale mixers.

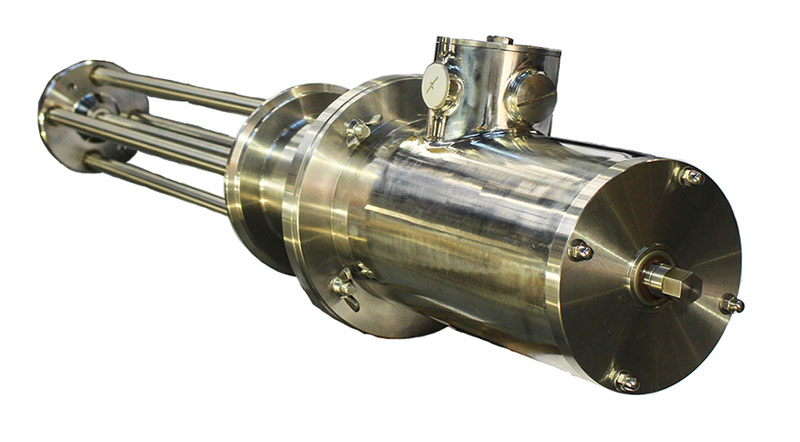

In this launch is the new 150 UHS inline mixer, which is designed for the ultra-hygienic applications typically encountered in the pharmaceutical, nutraceutical and biotech industries.

This mixer is especially useful when the smallest production-scale mixers may be too large, but laboratory equipment might not offer sufficient capacity.

This model is built to the same high specifications as production-scale UHS mixers and can be supplied with Silverson-designed hygienic single mechanical shaft seals, which can be converted to hygienic double mechanical shaft seals that are suitable for pressurised flushing.

They have a crevice-free construction and are designed for CIP and SIP operations.

Ideal for batches of up to 50 L, the mixer features a range of interchangeable workheads and screens, offering intense yet targeted high shear capability; a conversion kit allowing it to be used as a Multistage 088/150 is available.

The mixer can be supplied with data dossier documentation packages conforming to all regulatory standards, such as cGMP, US FDA and EC 1935/2004.