Dec Group has unveiled the Dec Safe Dock Valve — the latest addition to its ‘Containment out of the Box’ powder handling solutions.

Safe Dock Valve allows connection of a powder transfer system (PTS) flexible hose to rotating equipment in a fully contained way, using a unique split valve system.

The Safe Dock split valve can be used in various applications including:

- contained discharge from a dryer via continuous liner using the PTS — DosiValve system

- container sampling with a micro powder transfer system (MPTS)

- filling of suspension in a dryer.

In all cases it maintains full equipment function and flexibility, combined with very high degree of powder containment.

The valve is full bore with various internal diameters, from DN 25 to DN 80, matching PTS hose bores, to prevent any product blockages or obstruction to flow.

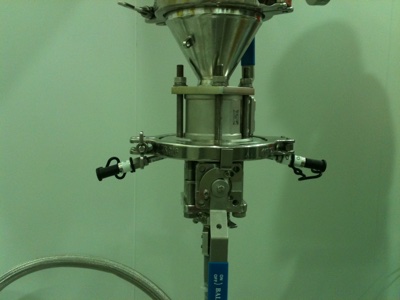

Safe Dock Valve: active section below

The split valve features a flexible ‘active’ section, hosting all valves and controls, that mates with a ‘passive‘ section that is rigidly attached to the equipment. This provides a solution that is easier to manipulate and operate, as well as a CIP capability that can be used before disconnection to ensure total containment.

In cleaning tests, a Safe Dock Valve that had been used for 1 hour of powder circulation (using lactose) was subjected to 3 minutes of cleaning with water injection. The result was no powder left inside the split valve.

The split valve system is also easy to dry. Water CIP cleaning, as described above, was followed by 5 minutes of drying with air injection resulting in all surfaces 99% water-free.

Safe Dock Valve, CIP connection

The Dec Safe Dock Valve delivers clear user benefits including the following:

- free and unobstructed powder flows

- assured high containment

- low occupational exposure limit (OEL) levels

- easy connection and disconnection

- direct access to valve controls

- easy and thorough CIP/SIP, drying.