FabRx, the biotechnology start-up that launched M3DIMAKER™, the world’s first commercial pharmaceutical 3D printer for the manufacture of personalised medicines, has recently showcased M3DISEEN, a novel AI platform to aid in the design of 3D printed medicines. The web-based software (available at http://m3diseen.com) uses machine learning techniques to accelerate and improve the process of designing 3D printed medicines (Figure 1). A significant leap towards the goal of truly personalised medicines that will revolutionise the way 3D printed medicines are designed today.

The software demonstrates FabRx’s commitment to embracing new and pragmatic technologies to achieve personalised medicines. This cross-disciplinary project was conducted in collaboration with researchers at University College London – School of Pharmacy (UK) and at IRLab from University of A Coruña (Spain).

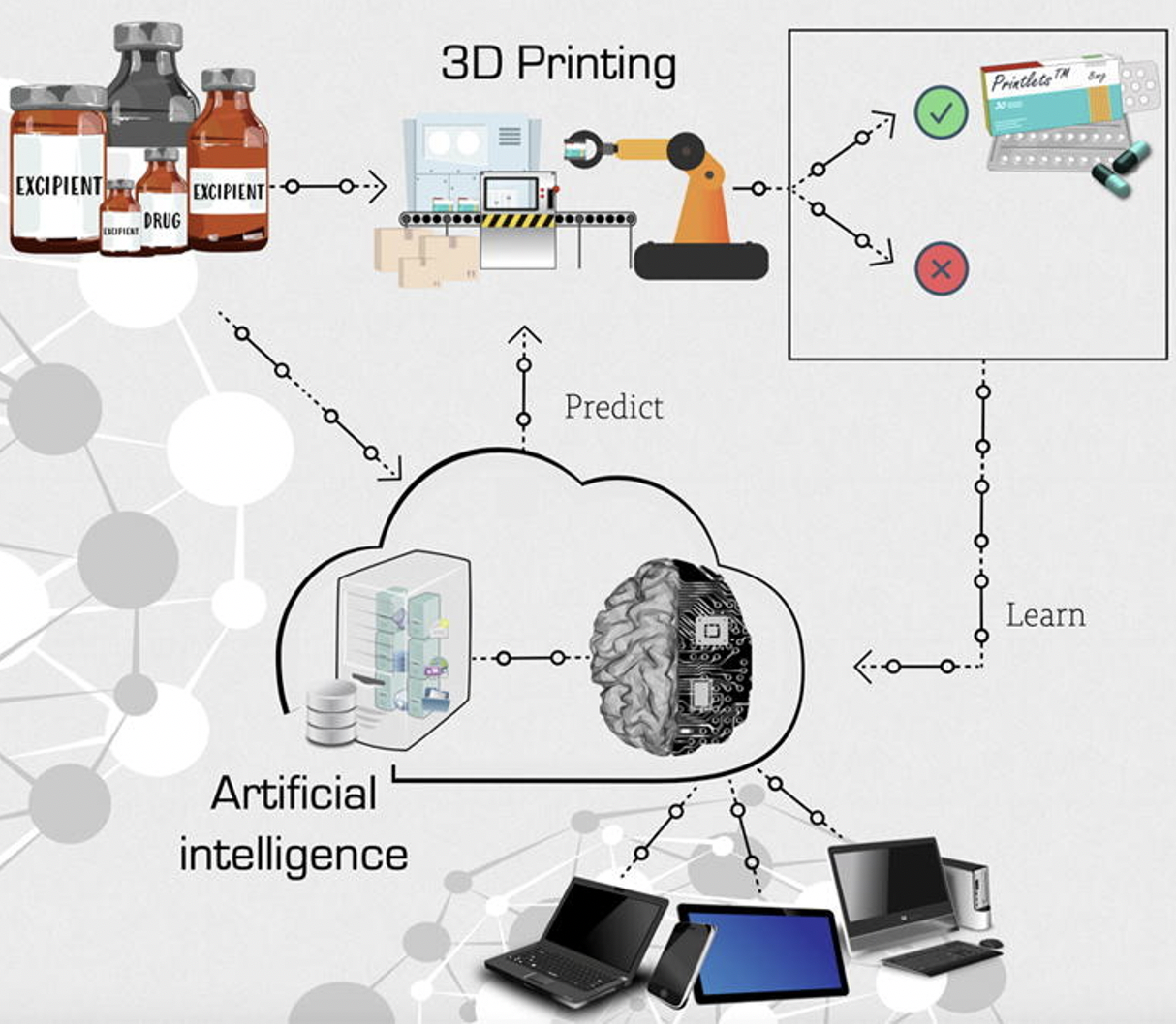

Figure 1. The AI lifecycle for 3D printed pharmaceuticals. Design, predict, print and learn

M3DISEEN has been designed to minimise the optimisation process, including predicting processing temperature, which for most practices is guided by rule of thumb. The AI platform is able to offer high levels of accuracy due to the hundreds of custom-made formulations generated by FabRx over a six-year period.

This new technology has the potential to revolutionise the 3D printing of pharmaceuticals by removing the need for expertise of the properties of materials individually and in combination. As such the design process is streamlined, saving crucial time and resources in early formulation development. Furthermore, M3DISEEN has the potential to be applied to other 3D printing techniques such as direct powder extrusion (DPE), one of the several innovative technologies implemented in FabRx’s M3DIMAKER™.