What is dry ice?

Dry ice is the solid form of carbon dioxide (CO2). A block of dry ice has a surface temperature of -109.3 degrees Fahrenheit (-78.5 degrees C), making it much colder than other freezing techniques.

Another benefit of dry ice is that it sublimates: as it breaks down, it turns directly into carbon dioxide gas, leaving no residue, unlike water ice which melts back into liquid form. The super-cold temperature and the sublimation feature make dry ice ideal for use in packaging when shipping products requiring sub-zero temperatures.

Why is the cost of gas impacting the availability of dry ice?

CO2 is a by-product of specific gas-reliant industrial activities. But, as gas prices increase across Europe, these industrial activities are being slowed or stopped altogether.

For example, CO2 is the main by-product of ammonia production, and with the recent announcement that U.K.-based fertiliser giants, CF Fertiliser (CCF) will temporarily cease ammonia production, stating that, ‘with current natural gas and carbon prices, CF Fertilisers UK’s ammonia production is uneconomical’, CO2 production will reduce significantly.

Industries that rely on CO2 have reacted with concern. The hospitality industry, for example, relies heavily on the CO2 produced as a by-product of ammonia production, using it to put the bubbles in fizzy drinks, and to transport temperature-sensitive food products using dry ice.

Cold chain logistics has also been hit hard by this news, as dry ice (which became particularly popular during the pandemic to help ship COVID-19 vaccines) prices have skyrocketed. Fertiliser producers in France, Germany and Italy have all reduced ammonia production in response to raising gas prices, which in turn is contributing to demand for dry ice.

Why are gas prices so high?

In February 2022, Russia invaded Ukraine. As a result, the international community hit Russia with numerous sanctions, including barring Russian officials from international travel, freezing bank accounts, and ceasing to export products and services to the country.

Despite the Kremlin claiming it is not using its gas supply as a political weapon, Russia has cut the amount of gas it sends to Europe by shutting the key Nord Stream 1 pipeline. The Nord Stream 1 pipeline stretches 1,200km (745 miles) under the Baltic Sea from the Russian coast near St Petersburg to north-eastern Germany and supplies up to 40% of Europe’s gas. Countries including Finland and North Macedonia have a 100% reliance on Russian gas, with Austria, Germany, and Hungary relying on Russia for over 60% of their gas.

The reduction in Russian gas exports has sent global prices soaring and has forced the EU to rethink its reliance on Russian gas. The European Commission has committed to reducing its reliance by two thirds by the winter of 2022/23, citing a reduction of fossil fuel reliance as being central to their plan, as they look to renewable energy sources found across the continent.

But, even with the plan for the EU to wean itself off Russian gas, shortages and therefore price hikes look likely to remain for at least the next few months.

What are the alternatives to dry ice?

We're here to help you keep your sub-zero cold chain moving. If you're shipping pharmaceutical or biologic substances requiring -15°C or below and have previously been reliant on dry ice, there are essentially two solutions to help you avoid rising costs and lack of dry ice availability:

1. 15°C to -25°C ShipmentsFor products requiring -15°C to -25°C temperatures, Intelsius ORCA phase change material (PCM) are useable and will keep your payload at the required temperature for 96+ hours. These specially design PCM can be pre-conditioned to ensure temperatures remain within the desired range for 96+ hours, ensuring the efficacy of your sub-zero payload. View and buy ORCA PCM here.

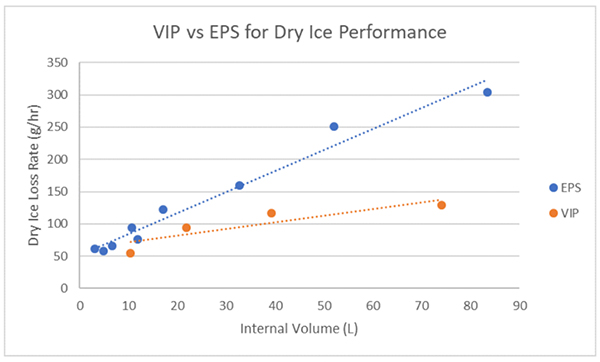

2. Reduce Dry Ice: VIPs versus EPSFor products requiring temperatures below -20°C, you will need to use dry ice to ensure its efficacy is maintained. In this case, seeking to reduce your dry ice use is the only option if you want to reduce costs during periods of global shortages.

All Intelsius ORCA dry ice solutions ensure a minimum of 120 hours of performance in even the most challenging cold chain conditions. The performance is achieved through interlocking Vacuum Insulated Panels (VIPs) that reduce the loss rate of dry ice, ensuring it can keep the payload at temperatures below -20°C for longer periods.

The graph below outlines the reduced loss rate when using dry ice in our VIP systems versus EPS systems.

View and buy dry ice ORCA VIP systems here.