As manufacturers continuously seek methods to enhance efficiency and reduce operational costs, the optimisation of chemical additives has emerged as a promising area.

Chemical additives such as biocides, antifouling agents, surfactants and flocculants are vital components in many manufacturing operations. However, these additives are often costly and optimising their use can yield substantial savings, particularly in continuous processes.

What is chemical additive optimisation?

Chemical additives play a crucial role when it comes to enhancing the efficiency and performance of manufacturing processes.

Despite their importance, the management and optimisation of these additives has traditionally been handled manually or semiautomatically, often relying on the expertise of chemical sales representatives or support from suppliers.

This approach is rarely optimised for cost efficiency. With the advent of AI and ML, there is now the potential to recommend optimal dosages for chemical additives based on real-time operating conditions, leading to considerable savings and improved process efficiency.

Case study

A compelling proof of concept was recently demonstrated in a modern reverse osmosis (RO) plant’s pretreatment unit. The primary function of the unit is to remove large particles and debris, thereby extending the lifespan and efficiency of the RO membranes.

The typical chemical additives used in this process include biocides, coagulants and flocculants. As biocides are dosed intermittently, the optimisation focused on coagulants and flocculants.

In this case study, AI-driven models helped to determine the optimal dosages of coagulants and flocculants. By analysing historical data and real-time operational conditions, the AI system could predict the most effective and efficient use of these chemicals.

Three approaches to AI/ML modelling

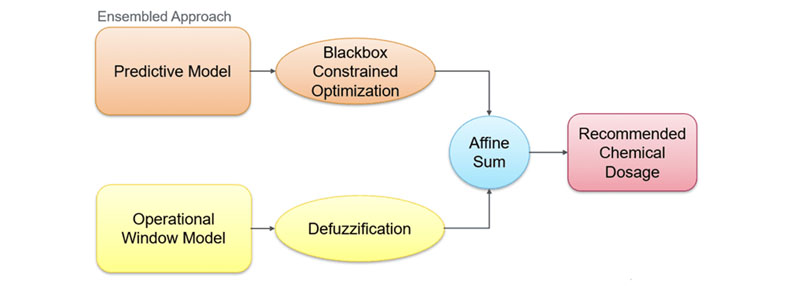

The modelling phase involves developing a predictive model and an operational window model, then combining these using an ensembled approach.

Predictive model

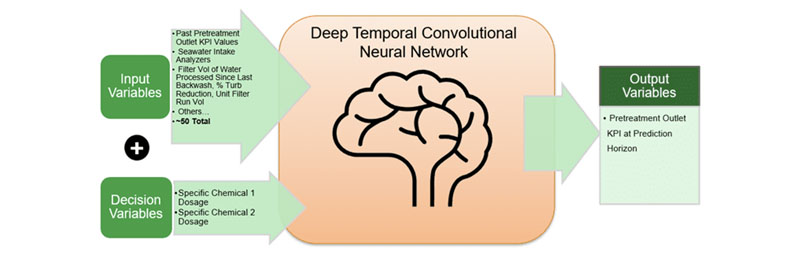

The predictive model aims to forecast key performance indicators (KPI) based on decisional variables and state variables as inputs. This model uses a constrained black-box optimisation method to provide optimal recommendations for the decision variables.

After testing several Deep Neural Network and Temporal Convolutional Network structures, the best-performing model was a modified Deep Temporal Convolutional Neural Network (DTCNN) based on the WaveNet structure (achieving an R2 score of 0.921).

The DTCNN model’s success underscores the potential of advanced neural network architectures when processing and predicting complex manufacturing processes. This model can handle the temporal dependencies and high-dimensional data typical of industrial operations, making it a robust tool to optimise chemical additive use.

Operational window model

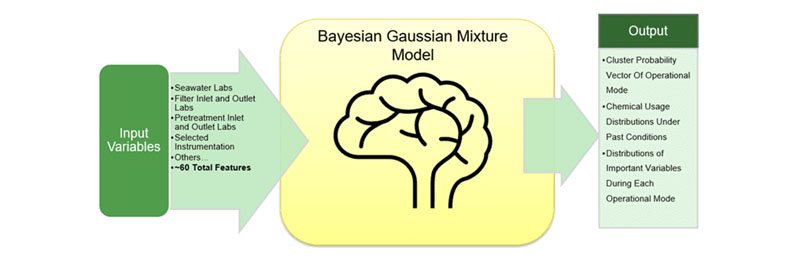

The operational window model identifies optimal operational modes using clustering methods such as Bayesian Gaussian Mixture Models. Each cluster represents a different operational mode for the plant and uses the best historical performance within each mode to guide current recommendations.

This model provides robust recommendations grounded in past performance, making it easier for plant operations to accept and implement.

The operational window model’s strength lies in its ability to contextualise current operations within a framework of past performance.

By doing so, it provides practical, data-driven recommendations that operators can trust because they are fully explainable. In turn, it facilitates smoother implementation and better adherence to optimal operational practices.

Ensemble approach

The ensemble approach combines the predictive model and the operational window model to provide a more balanced and robust recommendation. This method leverages high-availability sensor data and laboratory values from the operational window model and high-frequency DCS data from the predictive model.

Separating the inputs based on availability allows for a model that can produce an accurate recommendation. This is true even in situations when some of the more complex instrumentation is unavailable. The recommendations from both models combine and use an affine sum. This allows for adjustable and robust outputs.

The ensemble method ensures that the recommendations are not only accurate but also resilient to changes in operating conditions. This adaptability is crucial in dynamic manufacturing environments where conditions can fluctuate rapidly.

AI-driven optimisation gives companies a competitive edge

The application of AI/ML to optimise chemical additives in the manufacturing process has shown promising results. Markedly, in the case of the reverse osmosis plant, the optimised dosages of coagulants and flocculants led to significant cost savings and improved operational efficiency.

The ensembled approach provided a tuneable and robust system. This way, it could adapt to varying operational conditions and maintain high levels of performance.

The cost savings achieved with AI-driven optimisation were significant, demonstrating the economic viability of such advanced technologies. Additionally, the enhanced operational efficiency contributed to prolonged equipment lifespan and reduced maintenance costs.

This further emphasised the benefits of integrating AI into manufacturing processes.

The success of this proof of concept opens the door to broader applications of AI/ML in manufacturing processes.

Overall, as AI/ML models become more sophisticated and data collection techniques continue to improve, the potential for cost savings and efficiency gains in various manufacturing sectors is substantial.

The integration of AI-driven optimisation can lead to more sustainable and economically viable manufacturing practices, driving innovation and competitiveness in the industry.

Moreover, AI’s ability to process vast amounts of data and uncover patterns not immediately evident to human operators can lead to the discovery of new efficiencies and operational strategies.

This not only improves current processes but also fosters a culture of continuous improvement and innovation within manufacturing organisations.

Optimising your processes with AI

The use of AI and machine learning for chemical additive optimisation in manufacturing processes represents a significant advancement in industrial operations. The approach not only reduces costs but also enhances the efficiency and sustainability of manufacturing processes.

Likewise, these technologies will continue to evolve and their impact on manufacturing will grow. Subsequently, this will pave the way for smarter and more efficient industrial practices.

The future of manufacturing lies in harnessing the power of AI and ML to not only optimise processes but also to innovate and stay ahead in a competitive landscape.

With continued advancements and broader adoption, AI-driven optimisation will undoubtedly become a cornerstone of modern manufacturing. It will revolutionise how we produce goods and manage resources.