In a process, poorly flowing powders may cause hopper blockages, flow inconsistently, adhere to equipment surfaces and/or fail to blend readily. The addition of a flow aid at a suitable concentration can be a cost-efficient way to tackle these issues and may also help to prevent caking during storage. However, the effectiveness of such additives is dependent on the dispersion of a fine layer onto the surface of the host particle. This can be a demanding task, given that flow aids typically have a very fine particle size and an associated tendency to agglomerate.

Magnetically Assisted Impaction Coating (MAIC) is an innovative process for coating fine guest particles or small quantities of liquid onto larger particles, which has been shown to deliver stable long-term adhesion without causing major changes to the size and/or shape of the host.1,2 It therefore offers considerable promise for blending flow aids, an application in which the need for energetic dispersion must be balanced against the requirement to avoid particle damage. Pharmaceutical powders can be particularly problematic in this regard as they are often friable/delicate.

This article provides an introduction to MAIC and presents experimental data contrasting its performance with V-blending, a traditional technology for flow aid dispersion. Detailed analysis of the dynamic flow properties of citric acid in the absence of silica and blended with silica at different concentrations illustrates the potential of MAIC to deliver blends with enhanced flow performance.

Using flow additives

Flow aids allow formulators to significantly enhance the performance of powders, a prime example in the pharmaceutical sector being the inclusion of glidants and lubricants in tableting blends. These facilitate the production of high quality tablets at an economic rate by

- enhancing powder flowability, aiding rapid and complete die filling

- lubricating the ejection of finished tablets from the die, reducing wear on the press

- minimising adherence of the tablet blend to process equipment such as punch faces.

Commonly used flow aids include magnesium stearate and fumed silica, but no single additive works well for every formulation; both flow aid and concentration must be carefully optimised to meet performance targets.3 Flow aids enhance behaviour via a range of mechanisms, filling in and smoothing surface asperities, for example, thereby reducing mechanical interlocking and friction, or acting as “spacers” that increase interparticular distances and, correspondingly, reduce the strength of van der Waals forces of attraction within the powder. Such mechanisms are extremely effective in reducing the resistance that the powder presents to flow but rely on adequate dispersion of the flow aid to a uniform coating on the host surface. The blending process used to incorporate the flow aid therefore impacts its functionality and efficacy, directly influencing the economics of use.

Introducing MAIC

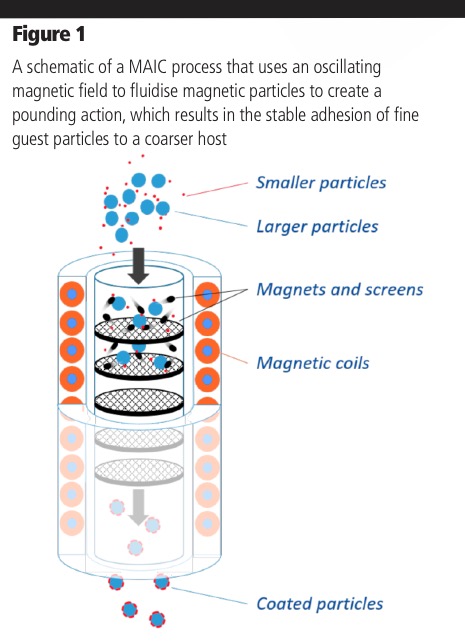

MAIC is substantially different from traditional techniques used for flow aid blending, such as V-blending, in that coating is actively promoted by the presence of magnetic particles (Figure 1).2 In a MAIC process, an oscillating magnetic field accelerates and spins relatively coarse magnetic particles (600–800 µm, though size may vary with application), causing them to fluidise and initiate a pounding process that coats the guest (flow aid) particles on to the host (core). The fine, guest particles adhere as a result of impaction, with collisions driven by energy transfer from the magnetic particles.

Operated as a continuous plug flow process, MAIC has been successfully scaled up from 1–6” and 18” diameter scales to give a maximum throughput in the region of 250 kg/h (although this figure is material dependent). A typical unit has eight screens and the guest and host materials are introduced either in the form of a premixed blend or as metered feeds. MAIC has been shown to produce highly stable, more uniformly coated particles than V-blending and therefore offers considerable potential for the enhanced blending of flow aids, as the following study demonstrates.4

Comparing the flow properties of citric acid/silica blends produced by MAIC and V-blending

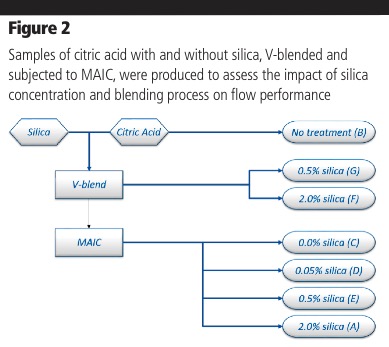

Citric acid (Hawkins Chemicals) was jet milled to a particle size of 5 µm and then preblended with 0.05%, 0.5% and 2.0% (w/w) fumed silica (Aerosil 200 Pharma, Evonik), particle size 12 nm, for 5 minutes using a V-blender with an intensifier bar. The resulting samples were then subjected to a MAIC process (AVEKA, Woodbury, USA), with experiments done in order of increasing silica concentration to minimise the potential for run-to-run contamination. An initial MAIC run was done using citric acid to assess the impact of the process in the absence of a flow aid. Figure 2 summarises the experimental programme and shows the samples gathered. Following randomisation, these samples were shipped for blinded analysis using an FT4 Powder Rheometer (Freeman Technology, Tewkesbury, UK). Dynamic flow, shear and bulk properties were measured for each sample and the results were then referenced to the processing conditions.5

Assessing the impact of silica concentration

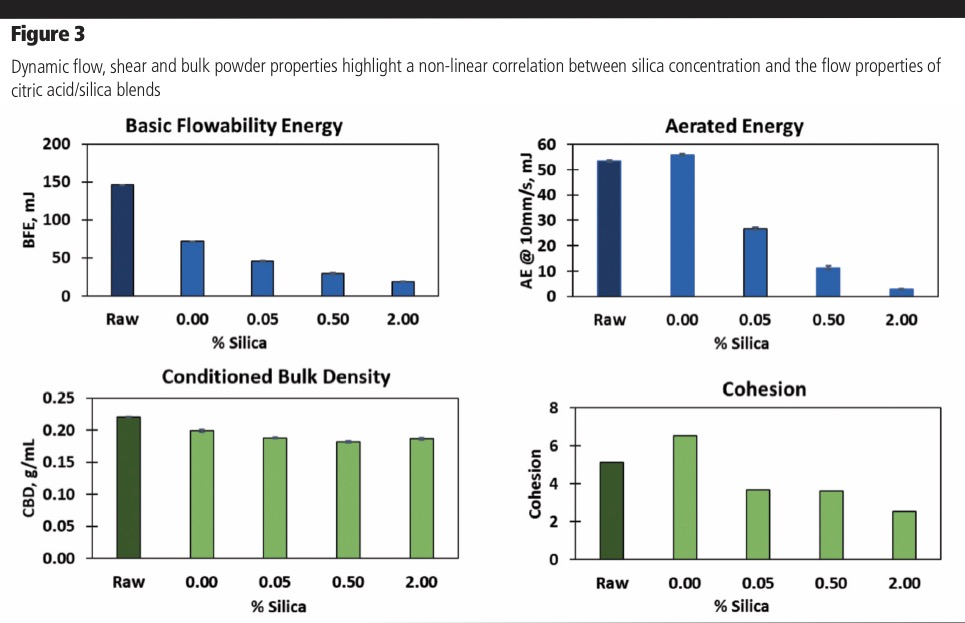

Analysis of the data for the four MAIC blends reveals the impact of increasing silica loading (Figure 3). These results show that BFE (basic flowable energy) reduces as the silica concentration is increased, although the correlation is not linear. The 0.05% w/w silica blend has a significantly lower BFE than the sample containing no flow additive, but the effect of adding more silica (a 10-fold increase to 0.5% w/w and higher) is proportionately less significant. Interestingly, the MAIC process has a marked impact on BFE in the absence of any flow additive and a similar reduction in SE (specific energy) is also observed (data not shown).

Conditioned bulk density data show that the samples containing flow aid are less efficiently packed than the raw citric acid sample and, again, this effect is observed in the absence of silica, with MAIC alone inducing a significant drop in bulk density. Lower bulk density values are indicative of wider interstitial spacing in the powder bed, improved separation of the particles and a higher proportion of entrained air, all of which can reduce resistance to flow. Increases in silica concentration above 0.05% w/w appear to have a minimal effect on bulk density, indicating they do little to change the overall efficiency of particle packing. Improvements in flow at silica concentrations in excess of 0.05% w/w, as observed in the BFE data, may therefore be attributable to mechanisms other than those related to packing effects, such as lubrication by the finer particles.

The AE (aerated energy) of the blends also decreases markedly with silica concentration, with the 2% sample approaching fluidisation under the test condition of an upward air flow rate of 10 mm/s. These data suggest that the flow aid significantly reduces absolute cohesion within the powder bed under low stress conditions and are supported in this regard by the shear data, which show that the inclusion of silica also results in lower cohesion under high stress conditions. However, the shear data shows little differentiation between the blends containing different concentrations of silica.

The primary conclusion from this part of the study is that the addition of silica improves the flow characteristics of the citric acid, as expected and as strongly evidenced by both BFE and AE data, but that the effect is non-linear. This is an important finding as it indicates that desirable flow performance may be achievable with relatively modest levels of flow additive, with little extra benefit being gained from the addition of further quantities. The data also suggest that the MAIC process itself may have a positive impact on powder flow characteristics, even in the absence of a flow aid.

One rationale for this is that the MAIC process smooths surface asperities on the primary particles, thereby reducing the mechanical interlocking and frictional effects that inhibit the movement of one particle relative to another. The magnitude of SE, which is dominated by these mechanisms, is much lower in the 0% silica, MAIC treated citric acid compared with the raw sample, supporting this argument. However, scanning electron microscopy has shown that MAIC typically results in only limited change to the properties of the host particle, which is an important feature of the process.1,2

An alternative explanation is that the MAIC process attaches fines already present in the raw citric acid, the fine particle fraction, to larger particles, enabling them to act as an intrinsic flow aid. This mechanism would have the effect of removing smaller, more cohesive particles from the bulk, at the same time increasing the interparticular spacing between larger particles. There is certainly evidence to suggest that MAIC increases interparticular spacing by some mechanism — as its application is associated with a reduction in bulk density, along with improved flow properties.

Comparing V-blending and MAIC for flow aid dispersion

Comparing the properties of 0.5% w/w and 2.0% w/w silica blends produced by V-blending and by MAIC highlights the impact of the processing technique on the flow improvement gained (Figure 4). These data show that the MAIC process produces samples with significantly enhanced flow properties relative to V-blending, at both silica concentrations, as evidenced by the BFE and AE data. Indeed, with respect to BFE, the 0.5% w/w MAIC sample is approximately equivalent to the 2.0% w/w V-blended sample while the AE data reflects the findings of previous studies when MAIC has been used in place of traditional blending methods to enhance powder fluidisation properties.6 Cohesion (shear data — measured under high stress conditions) is also lower in the MAIC samples, with the difference between the two processes more being pronounced at the lower silica loading.

Assessing the impact of flow additives

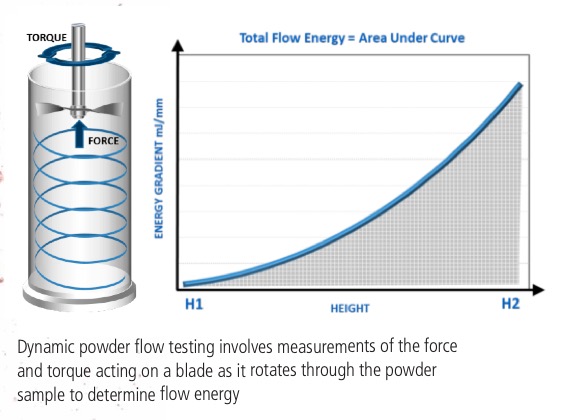

The optimal use of a flow additive relies on identifying a powder flow characterisation method that can robustly quantify its effect. Dynamic powder flow testing can be particularly helpful in this respect as it is highly differentiating and because the data generated has direct process relevance. Powders can be tested in a consolidated, moderate stress, aerated or even fluidised state to assess their performance under the conditions of most interest for a specific application.

Dynamic powder flow properties are determined from measurements of the axial and rotational forces acting on a helical blade as it rotates through a powder sample. Dynamic test methods are well-defined, largely automated and preceded by a sample conditioning step, gentle agitation of the bed, which ensures that the powder begins the test in a reproducibly, low stress homogenous state.5

• Basic Flowability Energy (BFE) is a baseline dynamic powder flow property that quantifies confined flow behaviour, as would be observed under forced flow conditions, in a screw conveyor or tablet feed frame, for example. It is measured during a downward traverse of the blade that exerts an aggressive compacting action on the powder, forcing it down against the base of the sample vessel. Other dynamic parameters that can be usefully measured to assess flow aid performance include

• Specific Energy (SE), which quantifies unconfined flow properties, how the powder behaves under gravity flow and is measured during an upward traverse of the blade.

• Aerated Energy (AE), which characterises the response of the powder to air, up to the point of fluidisation and is a measurement of BFE with air passing up through the sample at a defined velocity.

• Stability Index (SI), which indicates the propensity of the sample to change, to segregate for example and is the ratio of the last and first BFE values generated in a series of repeat measurements.

Furthermore, powder rheometers used for dynamic flow testing also typically offer the capability of measuring shear and bulk powder properties. Such instruments therefore provide a multifaceted approach to assessing the impact of a flow aid, supporting the robust optimisation of its use.

The SI (stability index) data show that the MAIC samples are also more stable, exhibiting only a minor change in flow energy during repeat test cycles. The V-blended samples, in contrast, have SI values less than one, indicating that flow energy reduces as testing proceeds. This behaviour is consistent with further dispersion of the fumed silica by the testing process itself. It is important to note that these samples were measured after shipping, which can often lead to consolidation and/or segregation. The data suggest that the MAIC samples may be less affected by transportation compared with the V-blended analogues and significantly less prone to segregation.

Taken together, these results indicate that MAIC produces powder blends that flow better under all flow regimes — low (AE), moderate (BFE) and high stress (cohesion/shear) — than the traditional technique of V-blending, with comparable levels of silica. This is consistent with previously reported results that indicate that MAIC creates a more uniform coating of flow aid than can be achieved via V-blending alone.4 Furthermore, the MAIC samples appear to be substantially more stable with a reduced tendency to segregate.

In conclusion

The optimal use of flow aids depends on identifying a suitable technique to assess their impact and the adoption of processing technology that effectively disperses the additive. This study illustrates the utility of dynamic flow, shear and bulk powder property measurement for assessing the effect of flow aid addition and the benefits of using the innovative process of MAIC for blending, relative to traditional methods. The results show that, with MAIC, it is possible to achieve comparable flow performance with much lower concentrations of flow aid than are required with V-blending, and that the resulting blends are far more stable. These findings directly support the sparing and economic use of flow aids to achieve flow performance goals and enhanced manufacturing efficiency.

References

- M. Ramlakhan, et al., “Dry Particle Coating Using Magnetically Assisted Impaction Coating: Modification of Surface Properties and Optimization of System and Operating Parameters,” Powder Technology 112, 137–148 (2000).

- W.A. Hendrickson and J. Abbott, “Process for Applying Liquid Coatings to Solid Particulate Substrates,” US Patent 5962082 A (1997).

- www.freemantech.co.uk/literature/application%20notes/ The%20Influence%20of%20Flow%20Additives%20on%20Powder%20Behaviour.pdf

- J. Yang, et al., “Dry Particle Coating for Improving the Flowability of Cohesive Powder,” Powder Technology 158, 21–33 (2005).

- R. Freeman, “Measuring the Flow Properties of Consolidated, Conditioned and Aerated Powders — A Comparative Study Using a Powder Rheometer and a Rotational Shear Cell,” Powder Technology 174, 25–33 (2007).

- R. Pfeffer, et al., “System and Method for Nanoparticle and Nanoagglomerate Fluidisation,” US Patent 7658340 B2 (2010).