Pharmaceutical companies across the world are significantly increasing their investment in more individualised approaches to treatment.

In fact, 42% of all drugs currently in development are associated with personalised medicine. Here Stephen Hayes, Managing Director at automation and control specialist, Beckhoff UK, explains how flexible manufacturing systems, supported by modular automation solutions, can meet the demands of advanced therapies.

Personalised medicine represents a shift from the one-size-fits-all approach to healthcare towards more individualised treatments. This change is driven by advances in genomics, biotechnology and data analytics, allowing treatments to be customised based on a patient's genetic profile, lifestyle and specific disease characteristics.

However, personalised medicine, which tailors treatments to individual patient profiles, demands an entirely different approach to production when compared with traditional mass production models.

This creates new challenges for pharmaceutical manufacturers as they must now be able to produce highly variable products in smaller batches while adhering to strict regulatory standards for quality and safety.

To successfully meet these requirements, manufacturing systems need to be highly flexible, scalable and adaptable. Traditional production lines that have been designed for mass manufacturing lack the necessary versatility to handle the complex and dynamic nature of personalised medicine. This is when flexible manufacturing systems come into play.

Agile production

Flexible manufacturing systems are designed to handle variations in product design, batch size and production processes with minimal reconfiguration. They enable manufacturers to switch between different product lines rapidly, making them ideal for the personalised medicine sector wherein variability is the norm rather than the exception.

Flexible manufacturing systems are characterised by their modularity and allow different components of the system to be reconfigured or replaced as needed. This modular approach not only supports adaptability but also enhances scalability, enabling manufacturers to quickly expand production capacity in response to changing demands.

Key to the success of flexible manufacturing systems is automation.

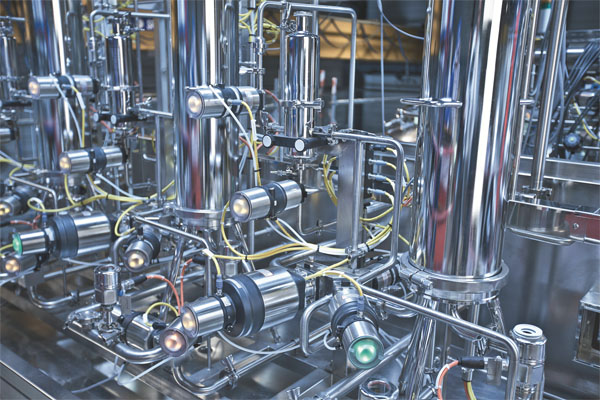

Advanced modular automation solutions, such as those supplied by Beckhoff, offer the tools needed to optimise flexible manufacturing processes. These systems can handle complex, multi-step production processes, reduce human error and maintain compliance with regulatory standards.

Regulatory compliance

Compliance with regulatory standards is non-negotiable in the pharmaceutical industry, especially with personalised medicine. Automated systems must not only ensure precision in manufacturing but also offer complete traceability, documentation and validation.

Automation can help to support compliance and tracing by allowing for integrated data acquisition and real-time monitoring.

For instance, TwinCAT from Beckhoff allows for continuous data recording and analysis throughout the production process, ensuring that all steps are fully documented and can be traced back if needed. This is essential when it comes to meeting regulatory requirements and ensuring product quality.

Beckhoff’s PC-based control systems also offer integrated support for good manufacturing practice (GMP) guidelines, which are crucial to maintain the safety and efficacy of pharmaceutical products.

By automating documentation and quality control tasks, these systems reduce the risk of human error and ensure that all products meet the necessary standards.

Efficiency gains

The modular nature of automation systems means that manufacturers can easily scale their operations. Whether they are producing a small batch of customised treatments or ramping up production to meet increased demand, automation solutions provide the flexibility and efficiency needed to stay competitive in the rapidly evolving pharmaceutical industry.

PC-based control solutions offer fast communication and precise control, reducing downtime and improving overall equipment effectiveness (OEE). The real-time feedback provided by these systems allows for quick adjustments to be made during production, minimising waste and ensuring that products are manufactured to exact specifications.

Flexibility and compliance

For personalised medicine, manufacturers need to create highly adaptable production environments that are capable of producing customised pharmaceutical products efficiently and compliantly. For this, high-speed, wireless communication is key as production lines may need to be configured frequently, bringing in new devices and modules.

By using a single, software-driven platform, PC-based control integrates various control tasks — such as PLC, motion control and robotics — into one system. This not only reduces hardware complexity but also allows for greater flexibility in programming and scaling the production line as needed.

Personalisation at scale

Beckhoff's eXtended Transport System (XTS) and XPlanar systems are two prime examples of how advanced automation can support the demands of personalised medicine.

The XTS is an intelligent linear transport system that offers unprecedented flexibility in motion control. It allows for the independent movement of individual carriers on a linear track, meaning that each product can be handled differently depending on its specific requirements.

This is particularly valuable in personalised medicine wherein different patients might require slightly different formulations or packaging. XTS enables pharmaceutical manufacturers to efficiently manage multiple product variants on the same production line, ensuring that each product is treated individually while maintaining high throughput.

Similarly, the XPlanar system provides magnetic levitation-based transport of objects on a flat plane, allowing for completely contactless and flexible movement of products. The system is highly adaptable, enabling individual processing steps to be customised dynamically without the need for mechanical reconfiguration.

In the context of personalised medicine, XPlanar’s ability to move and manipulate products without physical contact ensures a high level of sterility and precision, both of which are critical for compliance with regulatory standards.

As the demand for personalised medicine continues to grow, pharmaceutical manufacturers must adopt flexible manufacturing systems that are supported by advanced modular automation solutions.

By integrating these solutions into their production lines, manufacturers can not only improve efficiency and scalability but also ensure that they are well-positioned to deliver the personalised treatments of the future while maintaining the highest standards of quality and compliance.