At Interpack 2017, visitors will have a chance to discover what's new from IMA for the pharmaceutical industry. Hall 17 will be devoted entirely to IMA's latest innovations.

The IMA Group will present new machines and complete lines for the processing and packaging of pharmaceuticals. A special area will be dedicated to IMA Digital summarising the projects that represent the company's commitment to the evolution towards the Smart Factory and Smart Products.

Some of the new machines on display:

IMA Active

Continuous Manufacturing is one of the most important drivers for innovation within the pharmaceutical industry. CROMA, the new machine for continuous coating, is IMA's first step in this direction. Of the various manufacturing phases for solid dosage, IMA Active has decided to start from coating because this process fits between two inherently continuous processes: compression and packaging. In fact, CROMA is designed to work in-line with a tablet press machine for medium production output. IMA's team is ready to welcome the demand for innovation coming from companies and stakeholders, working together to design the future of pharmaceutical manufacturing.

IMA Life

Injecta is the ultimate frontier in the process of RTF syringes in tubs. The machine new design concept envisions the use of advanced robotics to ensure smooth processing of tubs and components with minimum operator's access to the working area. Quality control of production is the biggest advantage of this revolutionary concept in syringe filling.

Sensitive AP400 CW labeller from IMA Life

The Sensitive AP400 Compact is the IMA Life's latest development in the field of carton labelling. The reduced overall length of 1.400 mm allows effective and valuable integrations in the major challenging packaging lines, where space availability and high speed requirements are the foremost prerequisites to cope with.

Also on display, the new carton labeller, Sensitive AP400 CW, has been conceived to feature, as all Sensitive Series, the application of labels on three of the carton's sides, with positive transport system. A sophisticated 100% in process advanced check weighing system performs the quality control of the production.

IMA Safe

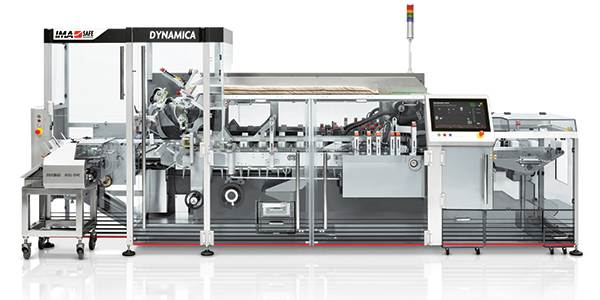

Dynamica from IMA Safe

Compared with previous models, the Dynamica offers improved ergonomics, a new HMI, no limits in terms of product feeding, and a new product bucket belt which allows better integration with the product feeder and a considerable reduction in size. Dynamica will be in-line with the new BFB MS260, a stretch banding machine and the new BFB CPH2 horizontal case packer.

Based on the success of the Sombrero (a one-row production feeder), a new double-row production feeder FILL-IT has been developed. It maintains the capacities of the Sombrero with the added benefit of being able to work in two rows.

In the Pharma area, visitors will also have the chance to discover the Process Innovation Hub, a corner dedicated to novel process technologies.

Continuous Pharmaceutical offers a breakthrough Integrated Continuous Manufacturing (ICM) technology for small molecule pharmaceuticals, where synthesis of the active ingredient and the final dosage form are integrated into a seamless process. This novel method allows "on-demand" manufacturing of pharmaceuticals with significant advantages in terms of production lead time, quality and costs.

Discover IMA's latest innovations for the monitoring, improvement and optimisation of the FREEZE DRYING PROCESS. IMA Life will be presenting a wireless sensor technology to advance pharmaceutical manufacturing.