The regulatory landscape is creating a more harmonised approach to technical and regulatory considerations for MLCM. Paired with analytical Quality by Design (AQbD), MCLM is set to change the way the pharmaceutical industry brings products to market.

The analytical procedures used to test pharmaceutical products throughout their lifecycle are undergoing continuous improvements. These advances are rapidly becoming a compliance expectation, with pharmaceutical companies being relied upon to apply an AQbD approach to product and method development.

AQbD, together with lifecycle management, ensures more robust methods that result in more consistent, reliable and high quality data. Method lifecycle management, also known as analytical procedure lifecycle management, encompasses AQbD to bring together analytical method improvement, qualification, validation, transfer and maintenance relating to good manufacturing practice (GMP).

In modern process management, the lifecycle focuses on the total costs of the process ... from investment to operation to retirement. The pharmaceutical industry has begun to apply this concept to the lifecycle of an analytical method — consisting of design, development, validation (including instrumental qualification, continuous method performance verification and method transfer) and retirement of the method.

The role of the industry’s regulators

The implementation of the International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use (ICH)’s guidelines Q8 to Q11 is helping to modernise the development and production of pharmaceuticals and apply a more scientific and risk-based approach to facilitate the continuous improvement and assurance of data quality.

Both the ICH and the United States Pharmacopeia (USP) Forum are developing new guidelines that include the lifecycle management of analytical methods. As part of MLCM, many pharmaceutical service providers are now using AQbD as an early risk assessment to clearly identify method parameters that have an impact on analytical performance.

In addition to the implementation of the ICH guidelines Q8 to Q11, a new proposed ICH guideline, Q12, will guide the management of post-approval changes in a more predictable and efficient manner across the product lifecycle.1

It has been drafted to create a more harmonised approach to technical and regulatory considerations for MLCM — as the existing guidelines take more science- and risk-based approaches to assessing change across lifecycles.

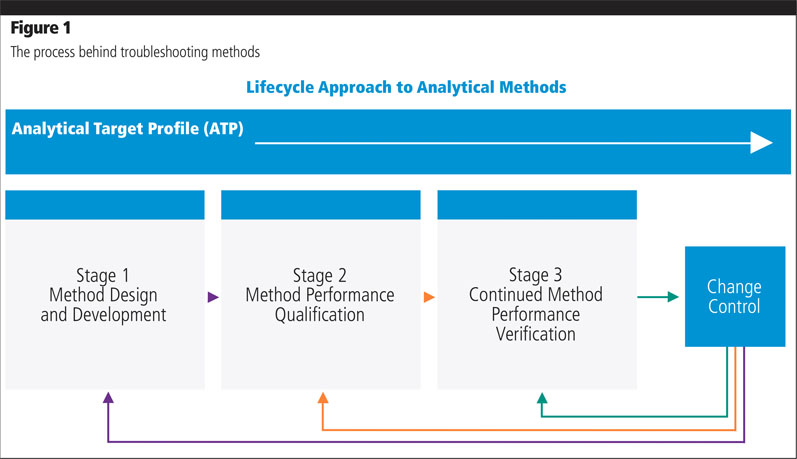

The adoption of ICH Q12 will promote innovation and continual method improvement, and strengthen quality assurance and the reliable supply of a product. In addition, further new ICH guidelines and a new general chapter of the USP are under way to provide specific guidance and a more strategic approach to MLCM across the product lifecycle … and to clarify the use of lifecycle management.2 There are three main stages of MLCM, which are outlined in ICH Q12 (Figure 1):

- procedure design and development

- procedure performance qualification

- continued procedure performance verification.

One of the challenges for pharmaceutical companies is troubleshooting existing or problematic methods. It may not be evident if poor results are from the method or product. However, the method can be evaluated with robustness testing, an AQbD process that is aided by reproducible analytical instrumentation and software. Often, by using this process, the method is found not to be robust and can be redeveloped to reduce variation.

Applying the analytical target profile

Defining the analytical target profile (ATP) is the first step of AQbD-based MCLM. The ATP represents the prospective overview of the aims of the analytical method, in addition to the quality requirements that the method must satisfy.3 It is a predefined, written record of the requirements of an analytical method and outlines the performance requirement for the analytical procedure.

It should be based on the method’s intended use and must be linked to its purpose rather than to an analytical technique.

The design and development of analytical methods can be progressed with the ATP — once the baseline is established — to define what is being measured and provide performance level characteristics. With the implementation of ICH Q12, the ATP will also be used as the basis for a regulatory submission and can be used to check how suitable the analytical procedure is in the early stages of drug development, as well as throughout the experiment.

ICH Q10 outlines a requirement for “the application of a holistic quality management system,” wherein an established ATP holds great value. It is a point of reference that can be used throughout the lifecycle if the need for change arises; and, applying this approach provides assurance that the quality objectives are being met throughout.

Taking a QbD approach

The method development and evaluation process can begin once the ATP has been defined. The AQbD approach sits under the MLCM umbrella and can be used as an early risk assessment tool to identify method parameters that have an impact on analytical performance, as well as risks associated with variability (such as sample preparation, instrument configuration and environmental conditions).

Improving the robustness of manufacturing processes, AQbD also facilitates continuous development strategies for enhanced product quality and productivity in manufacturing, encouraging both pharmaceutical manufacturers and regulatory agencies to apply these principles to products and processes. The resulting quality tool yields methods that will meet future requirements and developments, and aid the development of a more robust application within the design space.

The need for revalidation is minimised with methods developed using an AQbD approach as the impact of possible variables during a method’s lifetime has already been considered. The outcome is a systematic approach, which includes defining the method’s goal, evaluating risk assessment, developing a design space, implementing a control strategy and continually working on improvements to increase method robustness and knowledge.

Approximately half of pharmaceutical failures occur because an established method is not robust; an AQbD approach confers significant gains in this area with a very small change.4

Recognising what the problem is and knowing what to change is the primary challenge. With the regulatory authorities often overwhelmed with small changes to documentation, implementing AQbD would significantly reduce the frequency of requests for these minor amends. In turn, regulators would be able to focus on more significant changes or more important topics, benefitting the pharmaceutical industry, authorities and the consumer.

Innovative instrumentation

Pharmaceutical service providers have been able to show that the number of failures and transfer issues that occur during the method lifecycle are often reduced by using an AQbD approach. One CRO found a 50% cost saving compared with standard quality control methods because AQbD results in robust analysis techniques with minimal associated quality control costs and significantly shortened analysis run times. For commercial processes, the high quality of the data provided by AQbD methods may also allow for more timely data release, reduced regulatory risk and lower costs.4

Innovative instrumentation and software are particularly advantageous in troubleshooting methods because such tools need to be highly robust, dependable and reproducible, even for the most demanding separations. The prospect of changing an already approved analytical method can push pharmaceutical companies outside of their comfort zones, but it is easy to show how the issue can be solved by taking an AQbD approach. There is also greater regulatory flexibility because results that fall within the well-defined design space are not considered to be changes in the method.

Pharmaceutical companies and instrument manufacturers play a role in the proactive education of customers about the benefits of MLCM and AQbD, particularly regarding how these approaches can be used under the current guidelines to develop methods that are robust, user-oriented, designed for routine analysis, easily transferable to any laboratory and both time- and cost-efficient.

Data trending is the backbone of an AQbD approach. By enabling timely identification and actions, and controlling variability and risk, it can serve as the basis for continuous improvement during the product lifecycle. Data trending also contributes to reducing risk, lowering costs and improving regulatory compliance.4

Using instruments and software that enable laboratories to understand how sources of variability impact method performance is crucial. Adopting technology that can provide more information faster and earlier in the method development process is fundamental, along with software that can handle the data and ensure its integrity for successful MLCM.

Lifecycle management in the future

As global regulatory bodies continue to develop new guidelines that specifically address the lifecycle management of analytical methods, MLCM and AQbD approaches are set to have a big impact, changing the way the pharmaceutical industry brings products to market. The paradigm shift of MLCM moves the focus of pharmaceutical method development from regulatory compliance back to the scientific advances that are the catalysts for advancing the field of modern medicine.

References

- International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use, “Final Business Plan; Q12 Technical and Regulatory Considerations for Pharmaceutical Product Lifecycle Management,” 28 July 2014: www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q12/Q12_Final_Buisness_Plan_July_2014.pdf.

- USP Validation and Verification Expert Panel, “Proposed New USP General Chapter: The Analytical Procedure Lifecycle <1220>,” 17 October 2016: www.uspnf.com/sites/default/files/usp_pdf/EN/USPNF/revisions/s201784.pdf.

- F.G. Vogt and A.S. Kord, “Development of Quality-by-Design Analytical Methods,” Journal of Pharmaceutical Sciences 100(3), 797–812 (2011).

- Waters Corporation, “The Method Detectives: Building a New Business Model with Analytical Procedure (Method) Lifecycle Management,” January 2019: www.waters.com/chromicent.

This article will appear in the June edition of Manufacturing Chemist. In the meantime, read more articles like this in our May issue.