Finally able to host a full-blown physical event after lockdowns and the pandemic had scuppered the aspirations of previous editions, GEA Pharma & Healthcare’s Dr Jim Holman suggested that it was somewhat ironic that the plenary presentation on day one of Manufacturing Chemist LIVE 2022 featured a Zoom call!

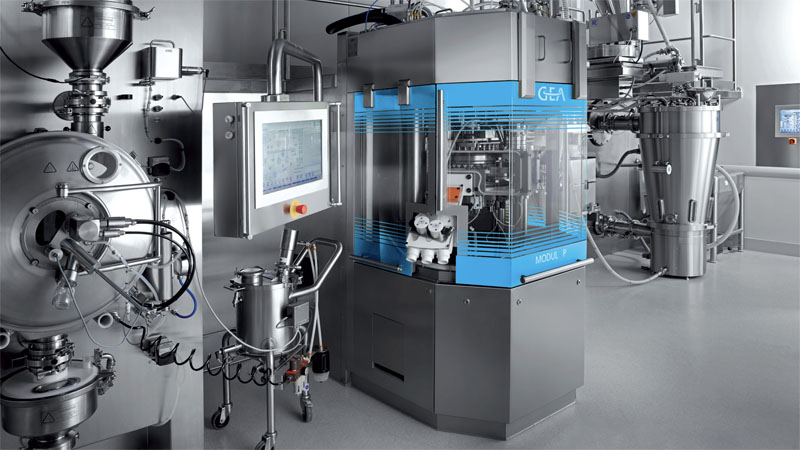

A slight understatement, of course, as he was referring to a simultaneous live-streamed video feed from the company’s GPSC (GEA Pharma Solids Center) test facility in Wommelgem, Belgium, of continuous manufacturing (CM) in action. The use of CM to produce oral solid dosage (OSD) forms has shown a number of key benefits to the pharmaceutical industry, including lower development times, increased operational flexibility and greater agility to deal with process changes.

Showcasing ConsiGma granulation and drying equipment (see image above), Jim’s talk on transforming the OSD forms of tomorrow with a continuous blended powder to coated tablet process also featured the revolutionary GEA Coater. A particular highlight for me was watching the almost instantaneous transition of cascading cores into coated tablets in a matter of seconds. Amazing to think that all this was possible within the constraints of a conference speaker’s time slot!

“Batch-less” manufacturing has been popular in the automotive, food and electronics industries for decades and generally refers to a process in which raw materials are taken from their beginning, all the way through to a final product, without a stop during production. “Going conti” is generally understood to be a quicker, more efficient concept (in terms of both energy and cost) with a lower footprint and no shutdown between batches.

Offering inherent benefits such as reduced time-to-market, lower development costs, increased flexibility, cost-efficiencies and the elimination of process pain points, Jim’s concluding points that CM represents both the future of pharmaceutical processing and the go-to-choice for new chemical entities (NCEs) within all major ethical companies going forward was well received.

A particular advocate was Dr Sara Fathollahi from DFE Pharma. Presenting an excipient manufacturer’s viewpoint of CM challenges, she examined in detail how and why understanding the functional requirements and interactions of excipients can expedite the transition from batch to continuous manufacturing.

“We believe this knowledge adds considerable value for drug companies who want to create novel formulations using CM and can leads to more successful outcomes.” She then demonstrated that, irrespective of the specific technique used, the particle size consistency, density and tabletability of excipients are critical properties during continuous wet granulation.

“The excipients play a particular role during each processing step and understanding the natural variation that occurs in terms of product knowledge may be key,” she said, adding that any good supplier should be able to provide valuable advice.

And, she suggested, a certificate of analysis doesn’t necessarily provide all the available information. “An open, two-way conversation between innovator companies and suppliers — that aligns with current IPEC/FDA thinking — is a key contributor to robust process success.

Patient-centric dosage forms

Dr Martin Koeberle from HERMES PHARMA reminded delegates that optimal oral drug delivery depends on more than just the active pharmaceutical excipient (API). To boost patient adherence, improve treatment effectiveness and reduce overall healthcare costs, the choice of dosage form is critical, he said, adding: “But, traditional tablets and capsules don’t always offer the best option. To develop truly successful drugs, the pharma industry must more carefully consider the needs and preferences of patients.”

Given that swallowing difficulties affect more than half of the global population, patient-centric user-friendly dosage forms (UFDFs) are incredibly industry relevant, said Martin. Using a series of case studies, he demonstrated advantages such as ease-of-use, convenience, increased compliance and their ability to accommodate large quantities of APIs.

Highlighting technologies such as hot melt coating for taste masking, he also examined the benefits of being able to offer a range of different flavours, single-dose delivery in a variety of formats (no measuring required) and the reduced risk of drug-induced esophagitis.

And, from a business perspective point of view, he reminded the audience that UFDFs offer economic benefits such as opportunities for line extensions, brand rejuvenation and patent protection, as well as optimising intellectual property strategies for NCEs.

Enter the excipients

Dr Michael Black from BENEO took to the podium to discuss the convenient formulation of orodispersible minitablets for paediatric administration. “Minitablets are a convenient and effective drug delivery system for patients and consumers who have dysphagia (swallowing problems),” he said: “Orodispersible versions have the further advantage in that they dissolve in the oral cavity within 30 seconds … enabling rapid drug release.”

His presentation covered the formulation, production and testing of the properties of the tablets — containing a WHO-listed active ingredient drug substance — with the results of the study demonstrating that low-dose enalapril maleate orodispersible minitablets can be successfully produced by direct compression using agglomerated isomalt (galenIQ) as a filler-binder.

For a deeper dive into Dr Black’s views about the trends and challenges facing today's pharmaceutical excipient market, check out our video interview with him here.

Continuing the ingredient theme, Shilpa Mistry from Chemlink Specialities reviewed the challenges that often need to overcome when working with poorly soluble drugs. Expounding the benefits of amorphous solid dispersion (ASD) technologies such as hot melt extrusion (HME), spray granulation and the use of highly purified polyvinyl alcohol (PVA) and hypromellose acetate succinate (AQOAT), respectively, she described the following advantages.

For HME, PVA as a plasticiser eliminates dose dumping, acts as a good alternative to cellulose, presents a narrow processing window and promotes super-saturation. During spray granulation, tests showed that solid dispersion using AQOAT in combination with L-HPC (low-substituted hydroxypropylcellulose) enhanced the solubility of nifedipine.

Furthermore, she noted that L-HPC as disintegrant can be used in the granulation and/or external phase, and that dissolution at certain pH can be designed by choosing the proper AQOAT grade.

And … breathe …

Rounding off the first day, Copley Scientific’s Anna Sipitanou gave the audience a “Quick Guide to Dry Powder Inhaler (DPI) Testing.” DPIs are an attractive option to an industry well used to powder formulations, she offered. Commonly used for the immediate treatment or alleviation of conditions such as chronic obstructive pulmonary disease (COPD) and asthma, most DPIs rely on a patient's inspiration effort to operate.

However, patients suffering from either of the aforementioned conditions will typically suffer from diminished respiratory function and may be less capable of producing a sufficient enough inhalation effort for effective aerolisation of the DPI.

Establishing guidelines for testing standards that represent common DPI use has been a longstanding task for regulators. Anna gave a comprehensive overview of the basics of DPIs testing and the current pharmacopoeial requirements for Delivered Dose Uniformity (DDU) and Aerodynamic Particle Size Distribution (APSD) testing — two of the critical quality attributes (CQAs) required to help determine the safety, quality and efficacy of all DPIs.

For more information about “what you missed” during the event, please take a look at the post from my colleague, Sophie Bullimore, and look at for the next instalment from me. I’ll be taking a look at Day Two in detail and some of the stragglers from Day One.